Shaping device of crocheting apparatus

A forming device and crochet machine technology, applied in crochet, knitted fabrics, knotting, etc., can solve the problems of unsuitable wire crochet, etc., and achieve the effect of saving raw materials, tall and straight appearance, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

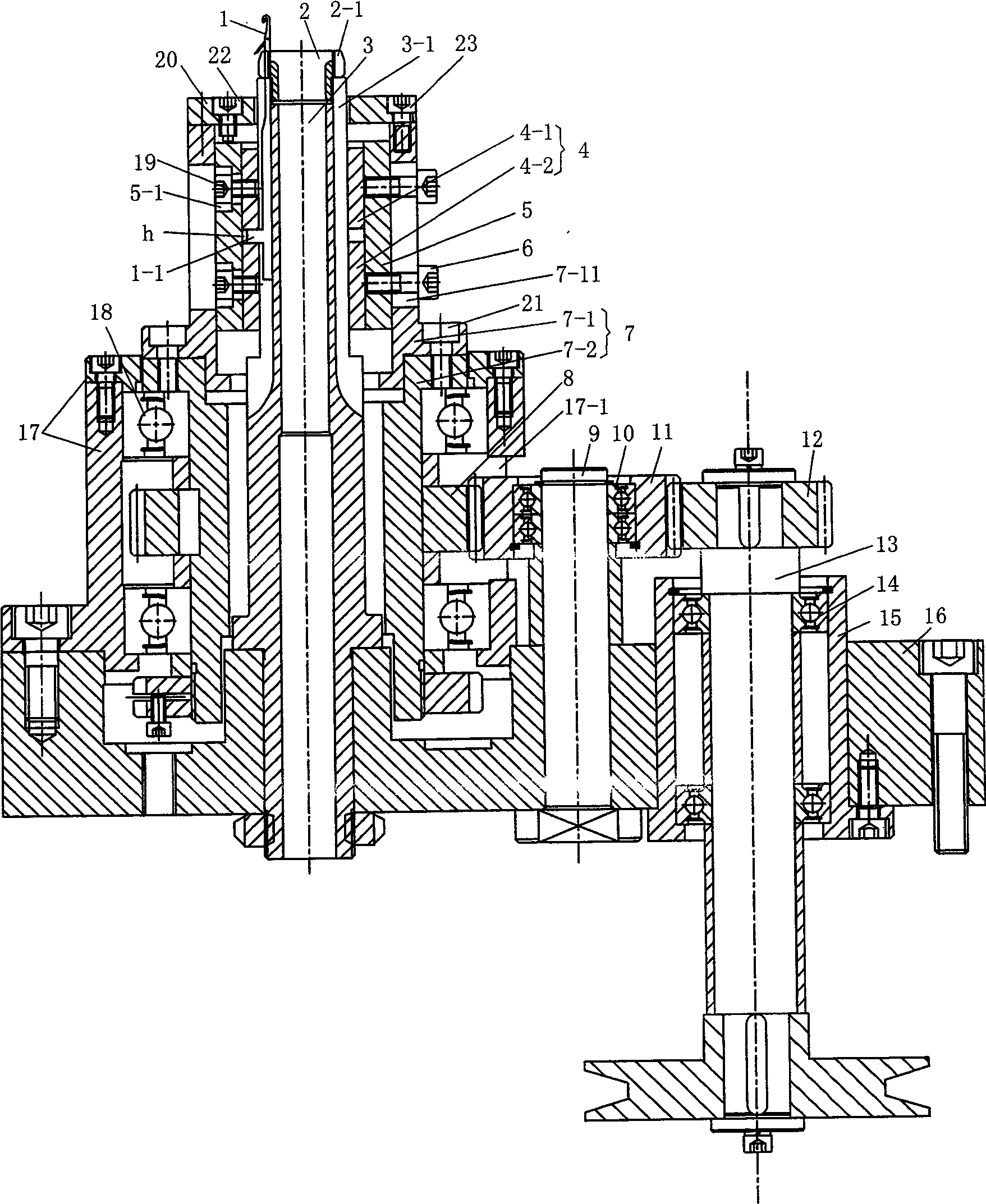

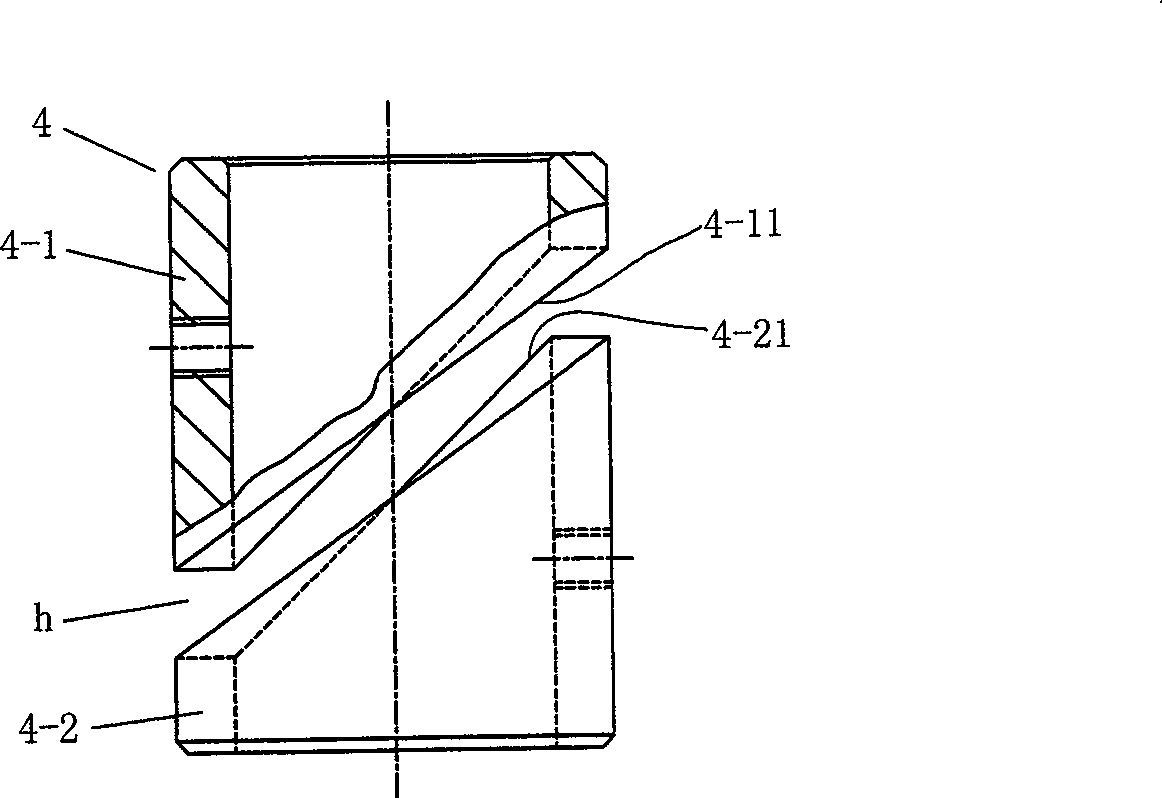

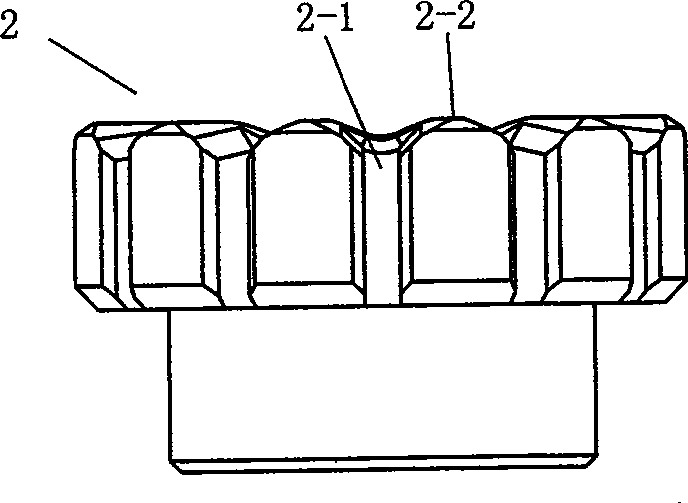

[0025] Figure 1 to Figure 4 The illustrated embodiment comprises a base 16 , a hollow mandrel 3 , a hollow forming head 2 , a drive shaft 13 . A molding head 2 is inserted into the upper end of the mandrel 3 . The cylindrical surface of the mandrel 3 is evenly provided with axial grooves 3-1, and the cylindrical surface of the forming head 2 is also uniformly provided with axial grooves 2-1. The number of axial grooves 3-1 is consistent. The top surface part 2-2 between two adjacent axial grooves 2-1 of the forming head 2 protrudes upwards in two stages of slopes to form a concave-convex surface. The hollow cavity of the forming head 2 and the mandrel 3 is the channel of the metal mesh pipe.

[0026] The bottom of described mandrel 3 is fixed in the mandrel hole of base 16, and bearing seat 15 is fixed in the transmission shaft hole of base 16, and transmission shaft 13 is supported by two bearings 14 up and down in bearing seat 15. The outer periphery of the upper and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com