Immersed tube prefabricated multistage under-reamed pile

A technology for expanding bottom piles and immersing pipes, which is applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve problems such as application limitations, adverse effects on end bearing, broken piles, necking, etc. Utilization, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

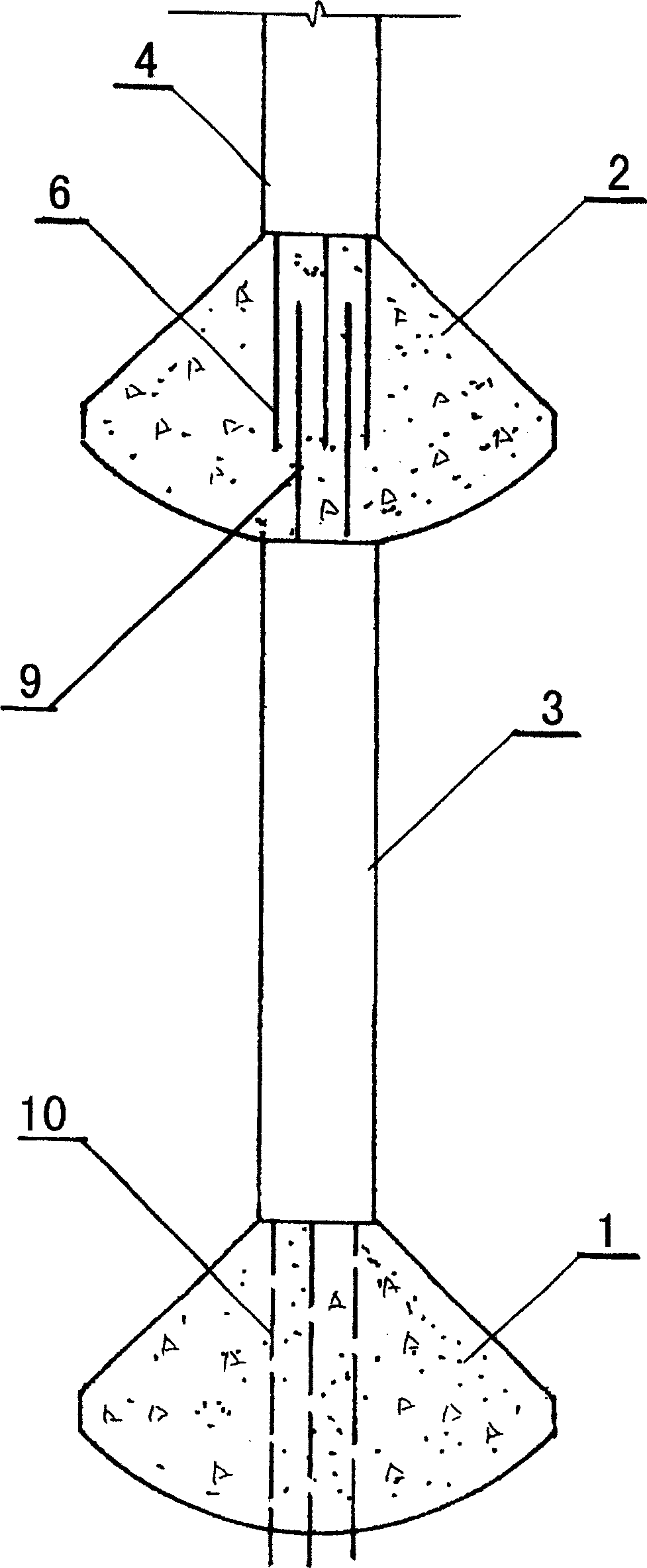

[0023] Such as figure 1 Shown is the schematic diagram of the main structure of the cast-in-place concrete base of the prefabricated pile body of the present invention, the upper section of the prefabricated prestressed pile body 4 is provided with the lower insert ribs 6 of the upper section of the prefabricated pile body, and the lower section of the prefabricated pile body 3 is provided with the lower section of the prefabricated pile The upper ribs 9 of the body and the pre-buried lower ribs 10, the upper ribs 9 of the lower prefabricated pile body overlap with the lower ribs 6 of the upper prefabricated pile body, and then the upper prefabricated prestressed The pile body 4 and the lower prefabricated pile body 3 are anchored together, and the lower end of the lower prefabricated pile body 3 is provided with a cast-in-place concrete base 1 . The construction method of this embodiment can be constructed according to conventional techniques.

Embodiment 2

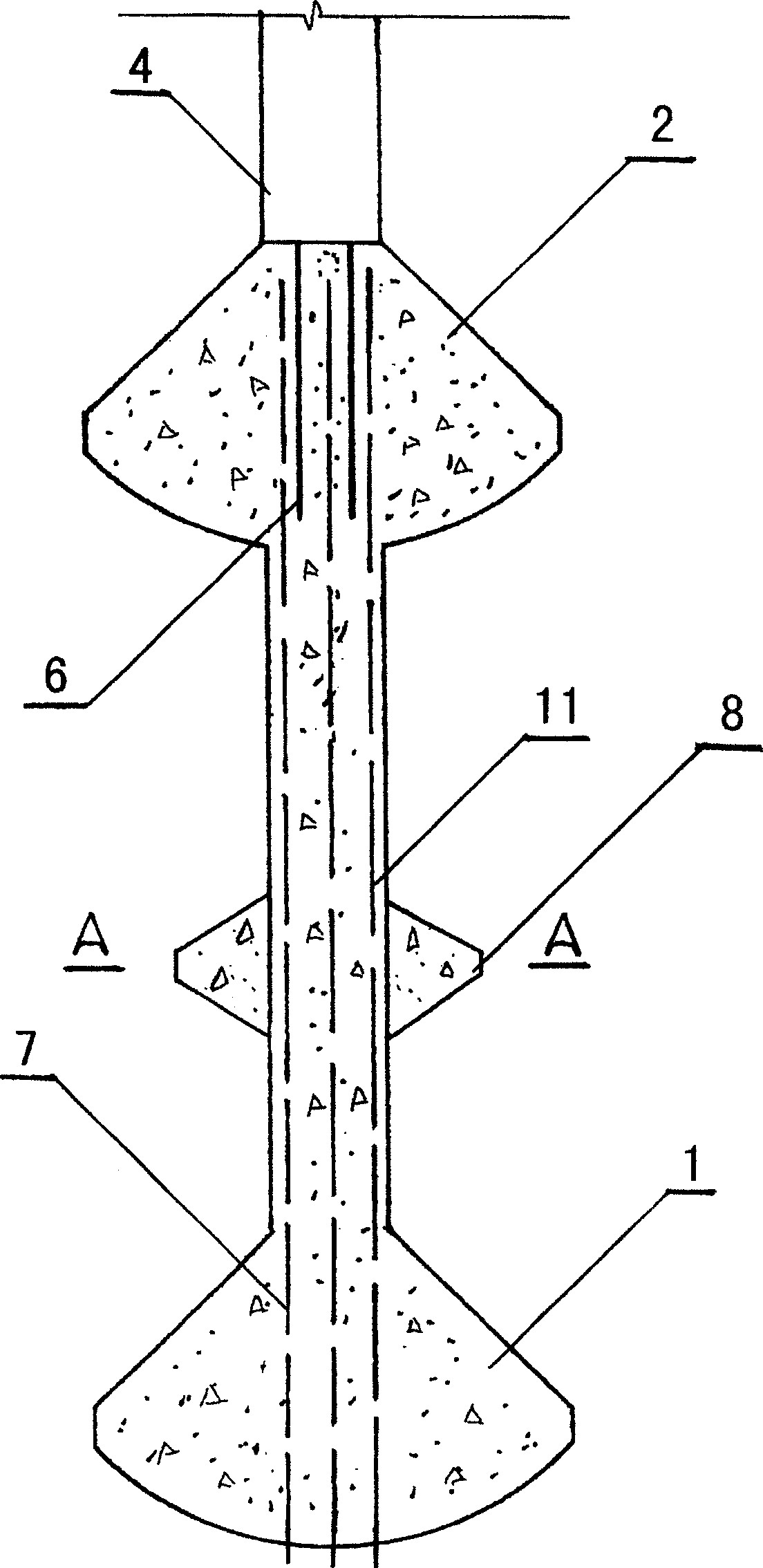

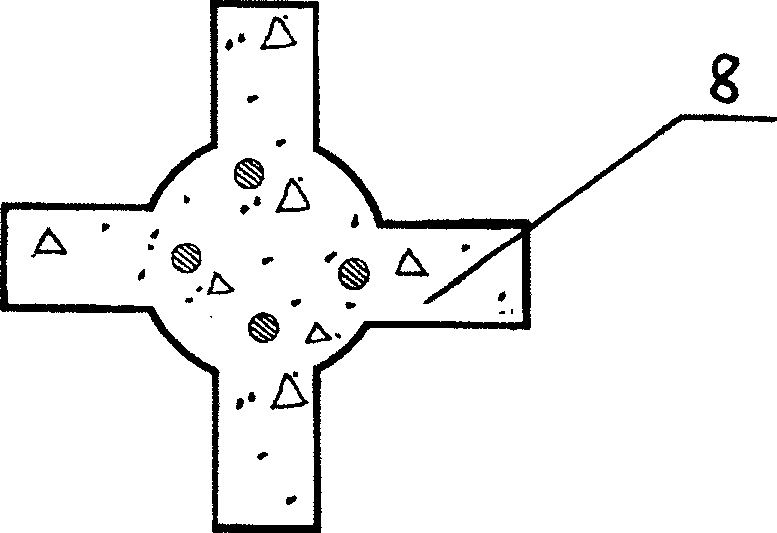

[0025] Such as figure 2 Shown, the pile body of the upper section is the prefabricated prestressed pile body 4 of the upper section, the pile body of the lower section is the cast-in-place pile body 11 of the lower section, and the ribs 7 of the cast-in-place pile body of the lower section of the cast-in-place pile body 11 are generally arranged and are connected with the prefabricated prestressed pile body of the upper section. The lower insert ribs 6 of the upper section of the prefabricated pile body embedded in the lower end of the pile body 4 are overlapped. The lower cast-in-place pile body 11 is provided with cross-shaped branches 8 for increasing the frictional resistance between the pile body and hard soil, such as image 3 The cross-shaped branch 8 shown in the figure can be extruded by YEJ800 hydraulic support plate forming machine to reproduce the cast steel concrete; or for the same purpose, the outer surface of the lower section of the cast-in-place pile body 11...

Embodiment 3

[0027] Figure 4 Shown is the lower insertion rib 6 of the upper prefabricated pile body 4 directly extending into the lower tubular prefabricated pile body 12 of the upper section prefabricated prestressed pile body 4, and the lower insertion rib 5 of the lower section prefabricated pile body arranged in the lower section tubular prefabricated pile body 12 Through the cast-in-place base 1 and nailed into the hard soil layer, one-stage, two-stage or multi-stage prefabricated or cast-in-place piles can be provided on the upper end of the upper prefabricated prestressed pile body 4 as required, and other structures are the same as those in the above-mentioned embodiment. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com