Wave-guide integrated on substrate-band-pass filter of coplanar wave-guide

A substrate-integrated waveguide and band-pass filter technology, which is applied to waveguide-type devices, waveguides, electrical components, etc., can solve the problems of high machining accuracy, bulky band-pass filters, and expensive band-pass filters. Achieve the effect of improving performance, simple design method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

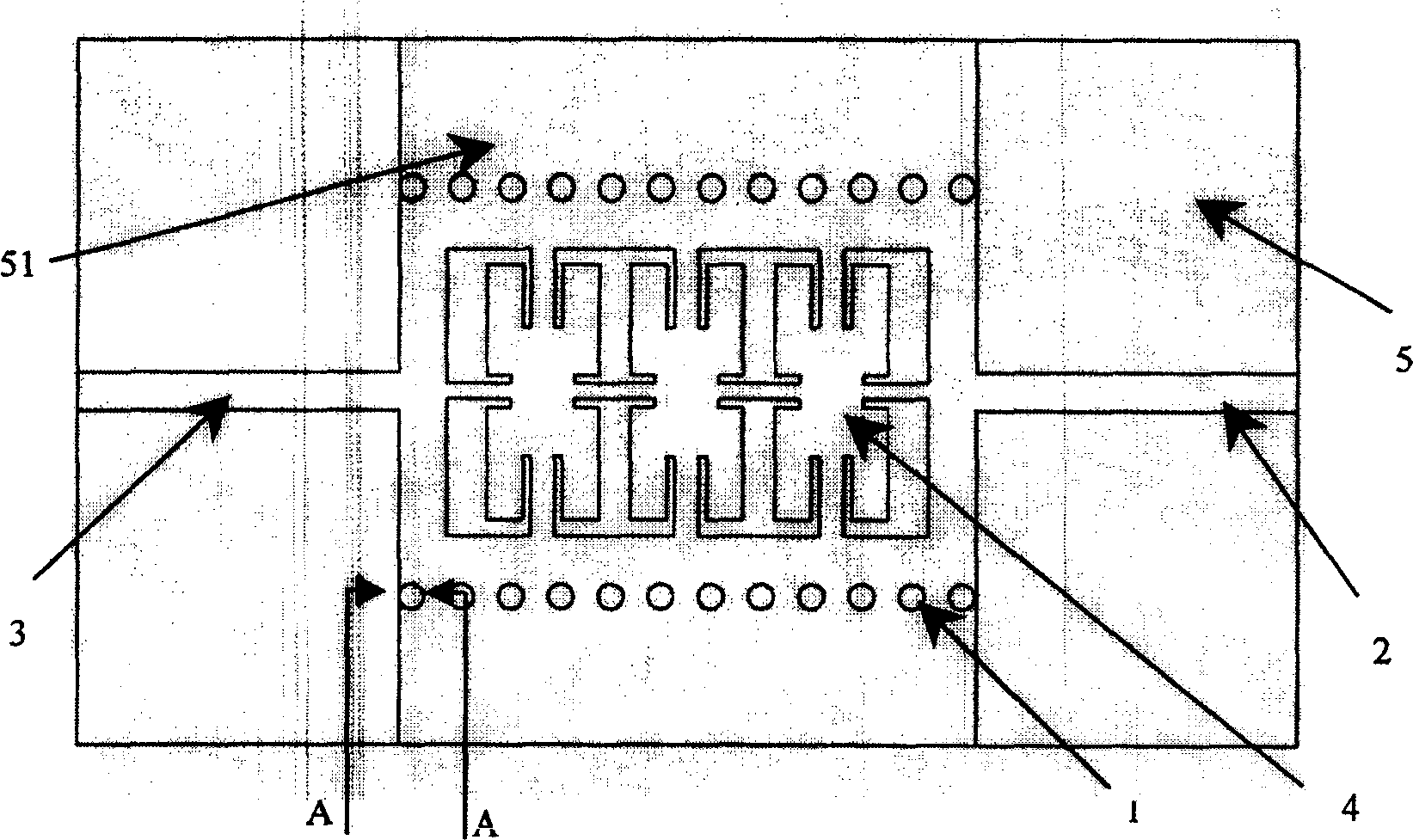

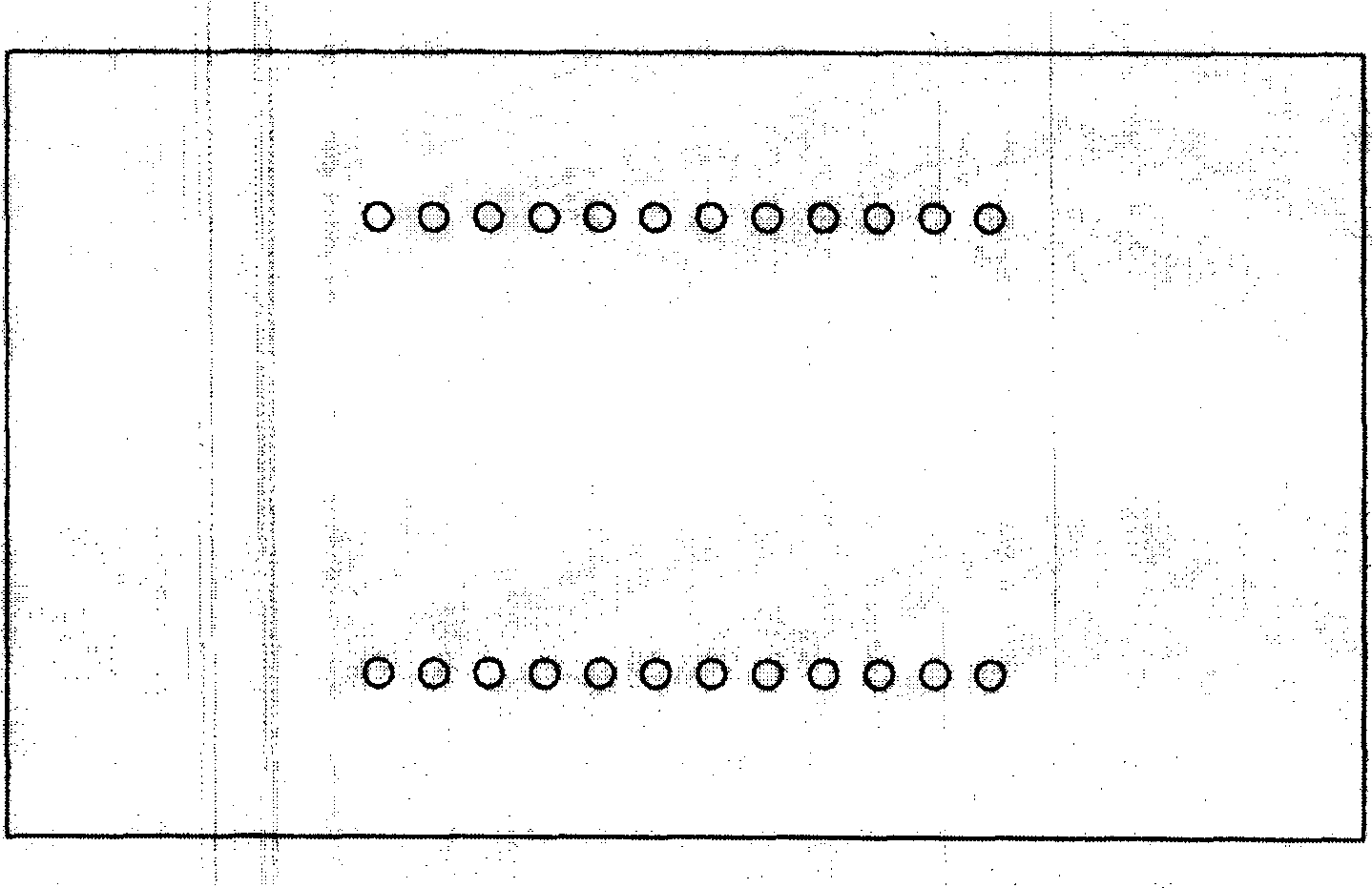

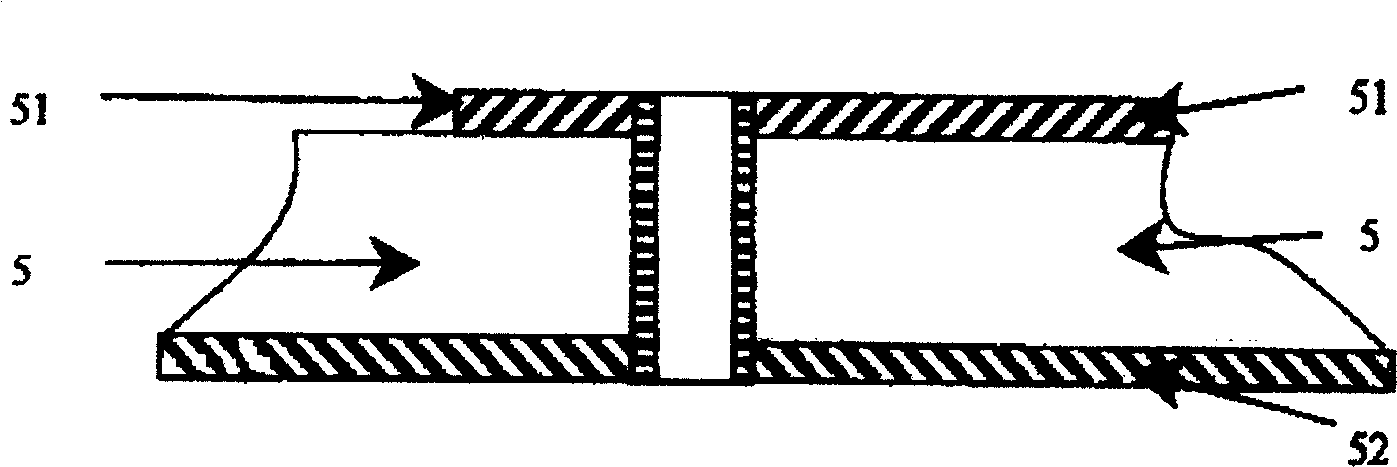

[0017] A substrate-integrated waveguide-coplanar waveguide bandpass filter, which is composed of a substrate-integrated waveguide and a coplanar-waveguide periodic structure, and an input terminal 2 and an output terminal 3 are provided on the substrate-integrated waveguide, and the substrate-integrated waveguide includes The dielectric substrate 5 is provided with metal patches 51, 52 on the upper and lower surfaces of the dielectric substrate 5, and at least two rows of metallized through holes 1 are arranged on the dielectric substrate 5. The metal patches 51 and 52 are connected by metallized through holes 1, and the coplanar waveguide periodic structure includes at least one coplanar compact coplanar waveguide unit 4 whose bottom surface is a metal patch, and the coplanar compact coplanar waveguide unit 4 Located inside the integrated waveguide of the substrate, the above-mentioned metallized through holes may be in 2, 3, 5, 8 or 11 rows. In this embodiment, the coplanar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com