Coating agent for recording layer protection and recording medium coated therewith

A recording medium and recording layer technology, applied to the surface coating liquid device, temperature recording method, coating, etc., can solve the problem of insufficient effect and achieve the effect of excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

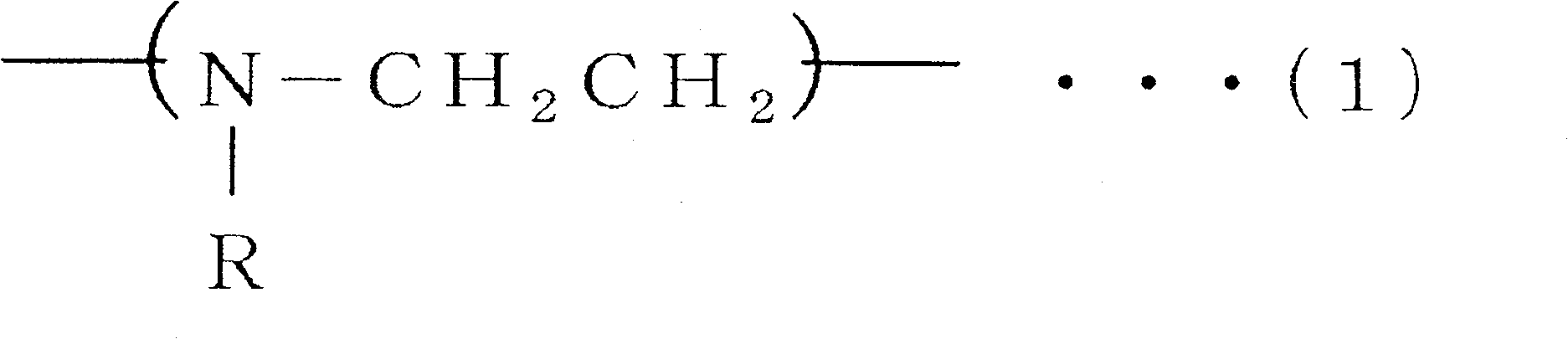

Method used

Image

Examples

Embodiment 1

[0050] Carboxyl-modified polyvinyl alcohol KL-118 manufactured by Kuraray Co., Ltd. was used as component (A), and heated and dissolved in water (cooked) so that the solid content concentration became 9%. Resin b obtained in the above synthesis example as component (B) and Catiofast SF (polyethyleneimine) manufactured by BASF Corporation as component (C) were added thereto, and they were respectively After reaching 5 parts, it was diluted with water so that the solid content concentration of KL-118 was 7%, and the coating agent D for protecting the recording layer was obtained. Table 1 shows the evaluation test results.

Embodiment 2

[0052] Except that the addition amount of resin b of component (B) was changed to the amount shown in Table 1, it carried out similarly to Example 1, and obtained the recording layer protection coating agent E. Table 1 shows the results of the evaluation test.

Embodiment 3

[0070] In the recording layer protective coating agent D obtained in Example 1, silica (P-527, manufactured by Mizusawa Chemical Industry Co., Ltd.) was mixed as a filler, stirred so that the solid content concentration relative to the liquid became 2%, and the Coated on the roll paper for facsimile machine ST138B41 (heat-sensitive recording paper without protective layer) manufactured by Pudokumento System Co., Ltd., so that the solid content was 3 g / m 2 Thereafter, drying was performed to obtain a thermosensitive recording medium F having a recording layer protective layer. Table 2 shows the evaluation test results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com