Paper taking module

A technology for supporting paper and paper, which is applied in the field of paper picking modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

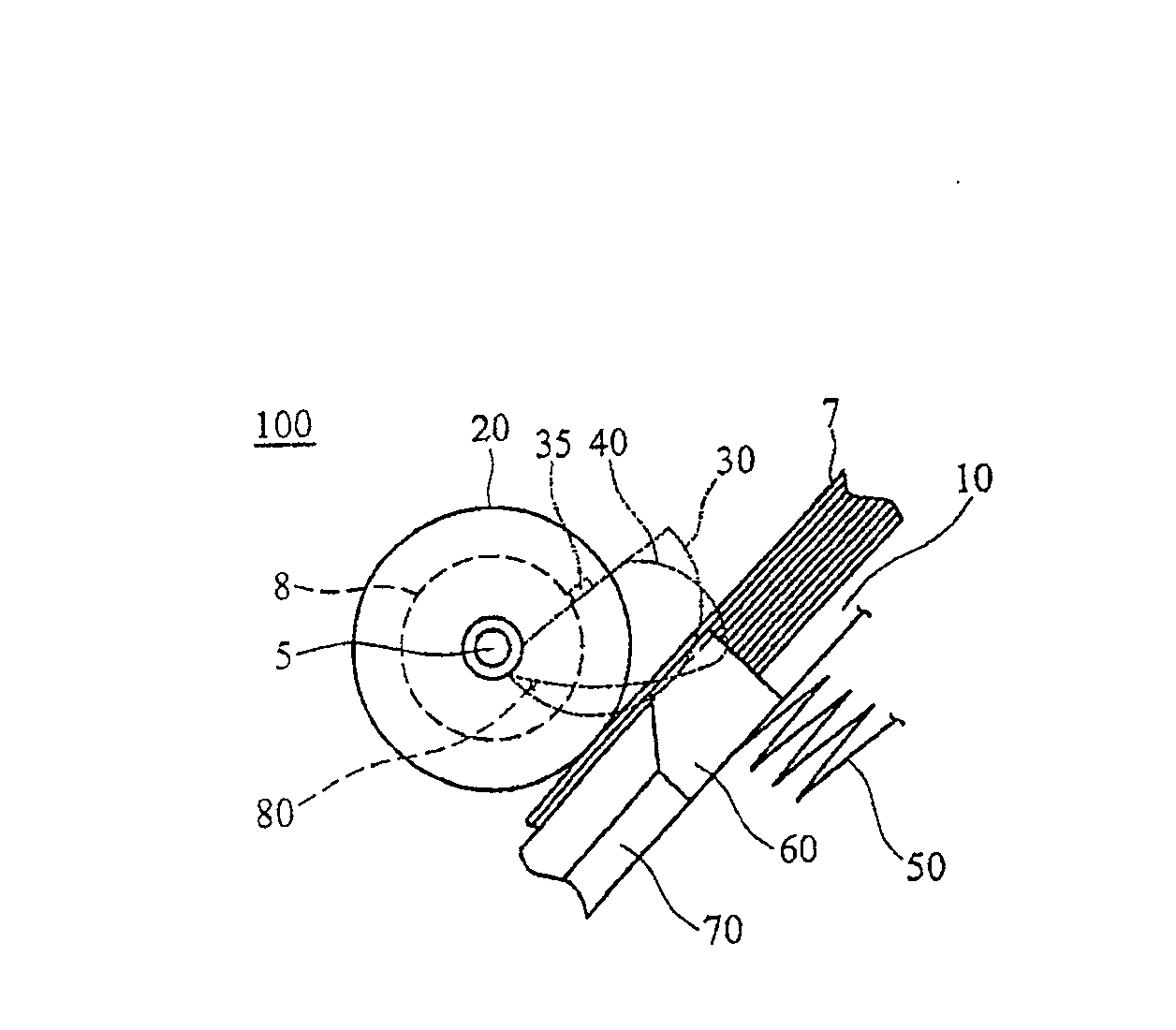

[0019] image 3 It is a schematic diagram of the first preferred embodiment of the paper picking module of the present invention. The paper pickup module 100 includes a paper holder 10 , a roll paper roller 20 , a first cam 30 , a second cam 40 , a first elastic member 50 , a first chute 60 and a second chute 70 . The paper holder 10 is used to carry the paper 7 for printing. The roll paper roller 20 is provided above the paper holder 10 and is in contact with the paper 7 for printing. The driving device 8 drives the roll paper roller 20 to rotate through the rotating shaft 5 . Both the first cam 30 and the second cam 40 are disposed above the paper holder 10 , and the second cam 40 is disposed adjacent to the first cam 30 . The first cam 30 is driven by the driving device 8 to rotate around the rotating shaft 5 , and the second cam 40 and the rotating shaft 5 can rotate relative to each other. Therefore, the second cam 40 is driven by the first cam 30 to rotate around the ...

no. 2 approach

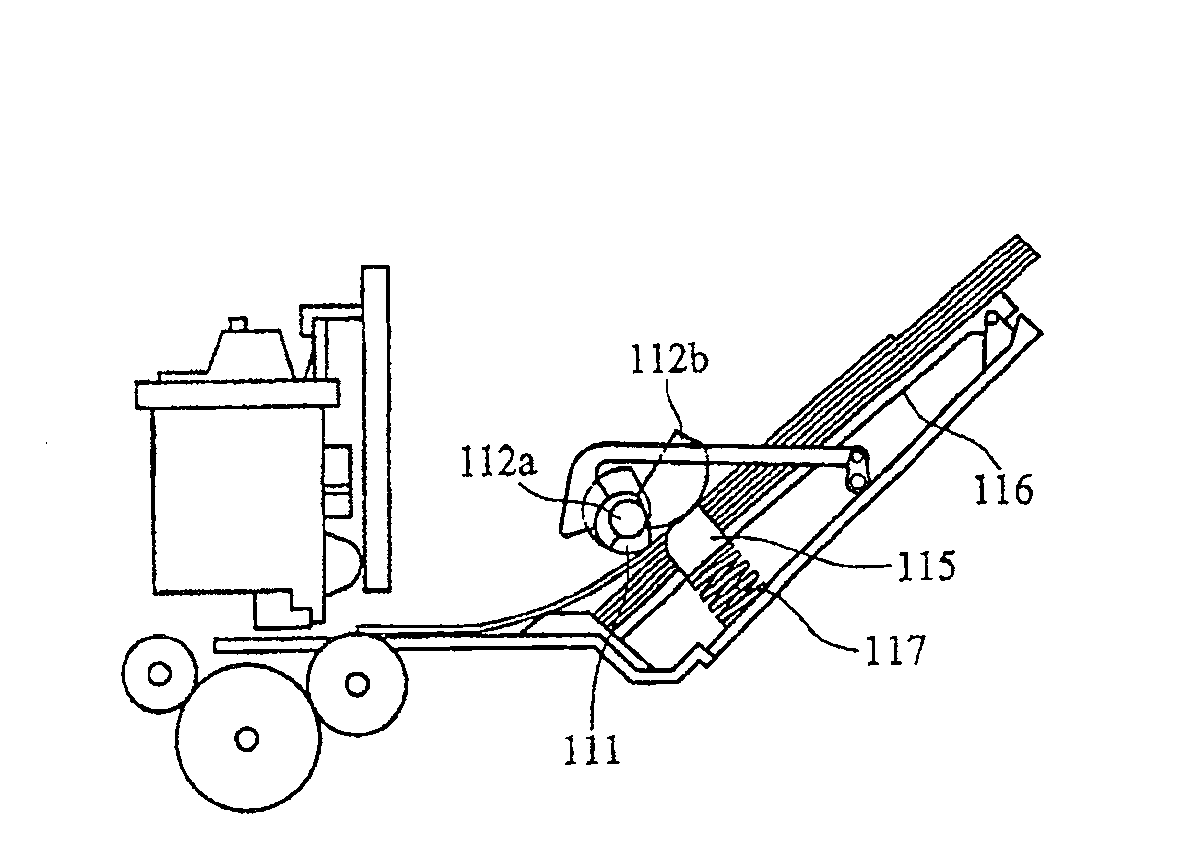

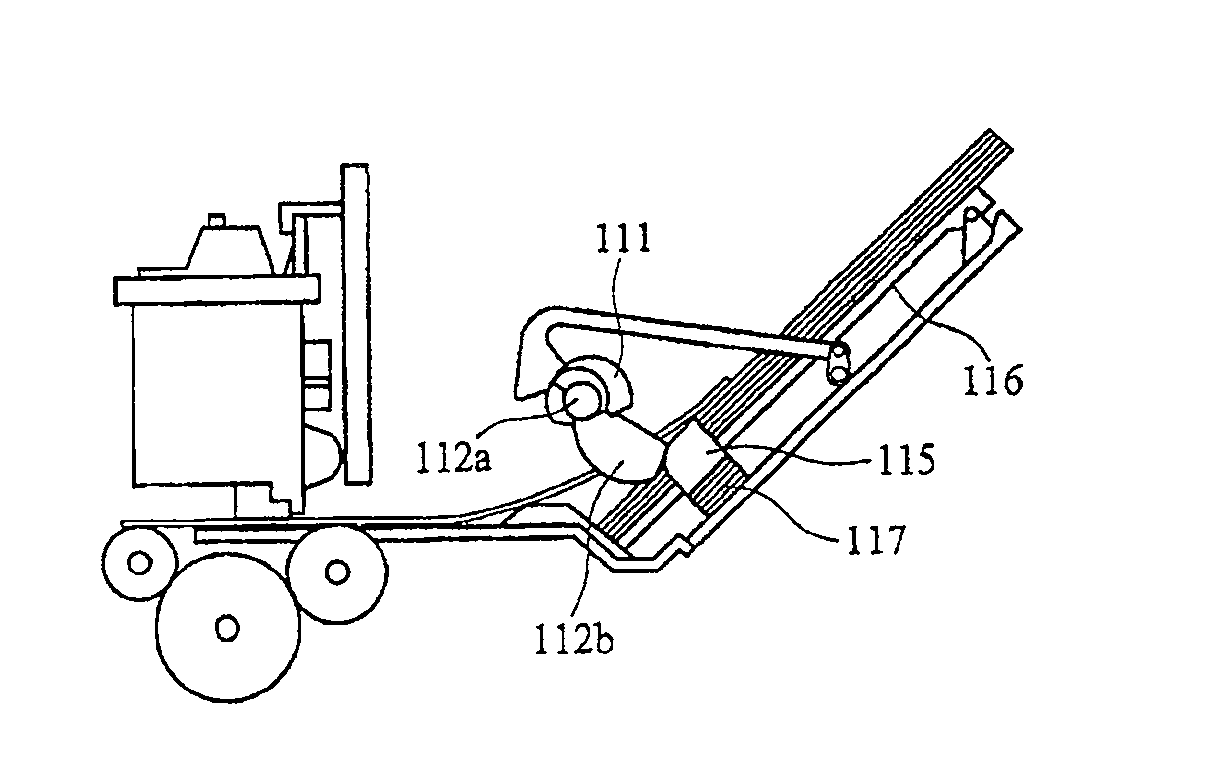

[0027] The second preferred embodiment of the paper picking module of the present invention is as follows: 11A to 11D shown. The paper pick-up module 100 includes a paper holder 10, a roll paper roller 20, a first cam 30, a second cam 40, and a first elastic member 50. The structure, function and mutual relationship of each component are substantially the same as those in the first embodiment, so the same The components are denoted by the same reference numerals. However, the relative positions of the first cam 30 and the second cam 40 in this embodiment are different, that is, the first cam 30 is on the inside and the second cam 40 is on the outside. Notches 12 are formed in the side walls to provide space for the first cam 30 to rotate, while flanges 18 extend from the edge of the paper holder 10 . In this embodiment, an opening slot 90 is further included. The opening slot 90 is formed in the notch 12 and is located on the flange 18. When the first cam 30 rotates, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com