Radiating system of light-emitting diode

A technology for light-emitting diodes and heat dissipation systems, which is applied to semiconductor/solid-state device components, semiconductor devices, electrical components, etc., and can solve problems such as deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

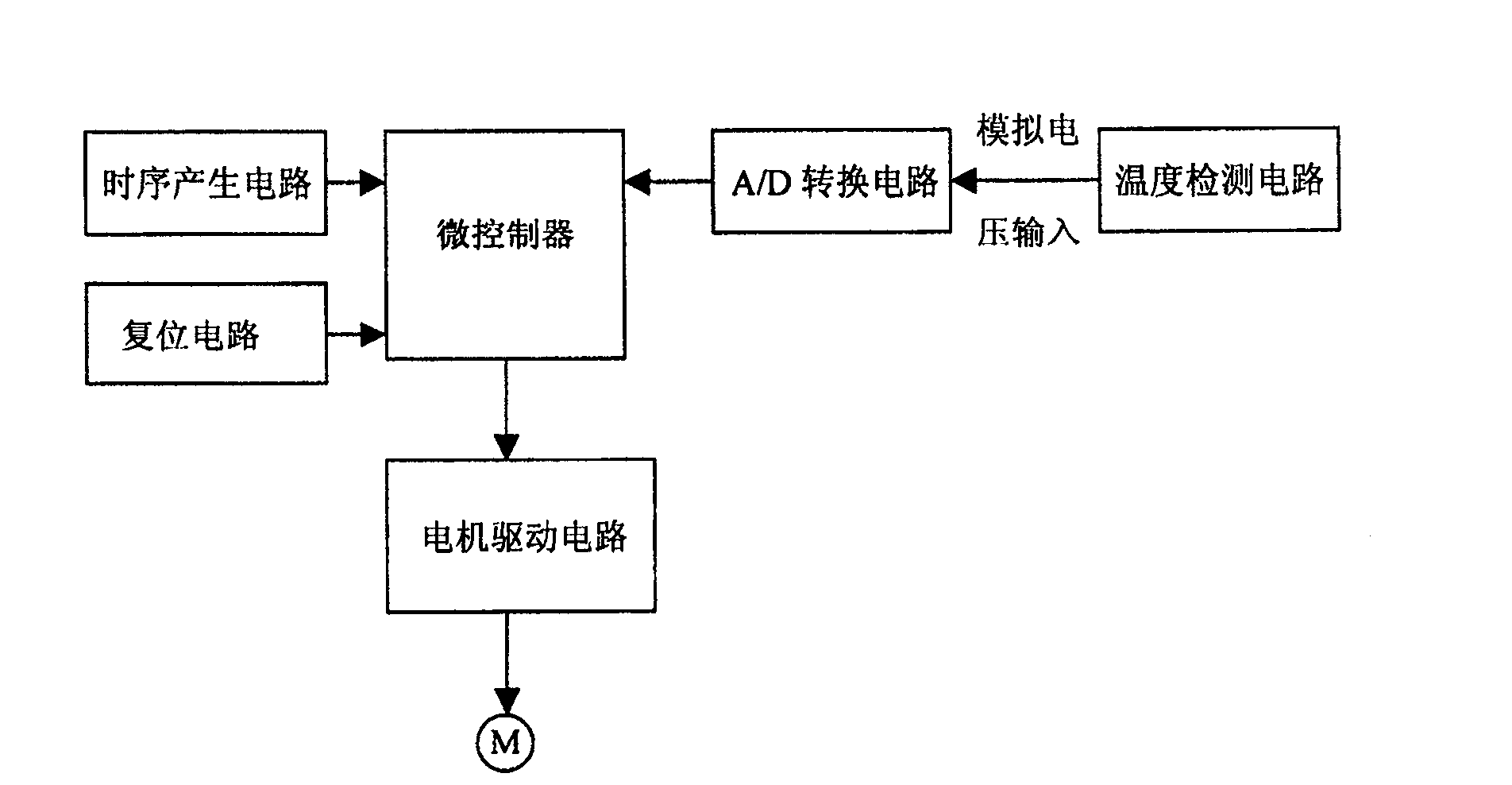

AI Technical Summary

Problems solved by technology

Method used

Image

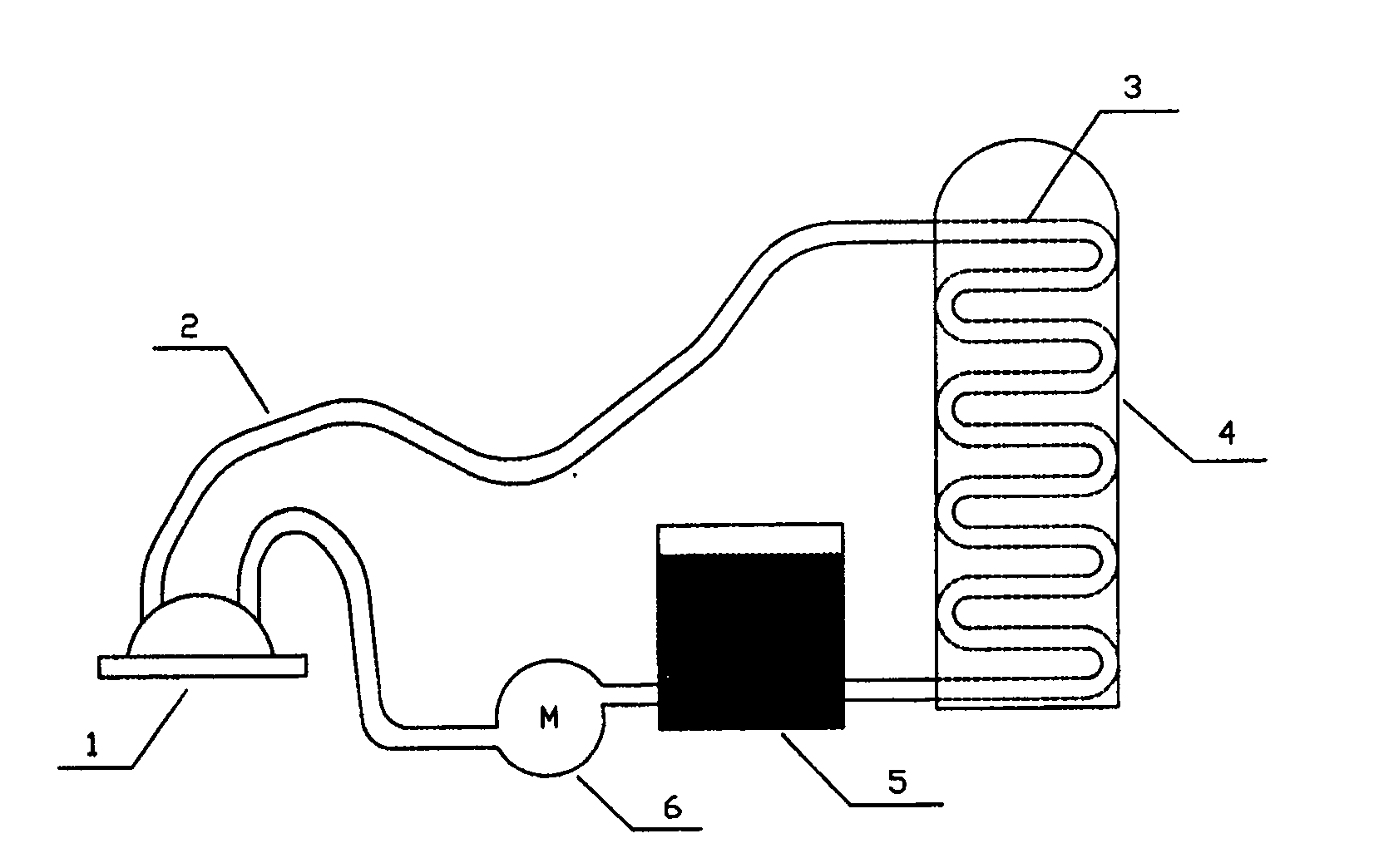

Examples

no. 2 approach

[0039] see Image 6 , other circuit parts are the same as the first embodiment, wherein the motor drive circuit is changed to a second control chip IC3 specially used for motor drive, wherein the first terminal and the fourth terminal of IC3 are output terminals, and are connected with the motor Connected, the second terminal and the third terminal are integrated circuit working voltage terminals, the fifth terminal and the eighth terminal are connected to the analog ground, the sixth terminal and the seventh terminal are logic variable input terminals, respectively connected to the first A control chip IC1 has a fifteenth connection terminal and a sixteenth connection terminal.

[0040] The working mode of the second control chip IC3 is as follows: the sixth terminal and the seventh terminal are logic variable input terminals, the first terminal and the fourth terminal are output terminals, and the logic relationship is as follows: when the sixth terminal inputs a high level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com