Vacuum processing device, diagnostic method for static electricity chuck and storing medium

A technology of vacuum processing device and electrostatic chuck, which is applied to positioning devices, circuits, electrical components, etc., can solve problems such as electrostatic damage and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

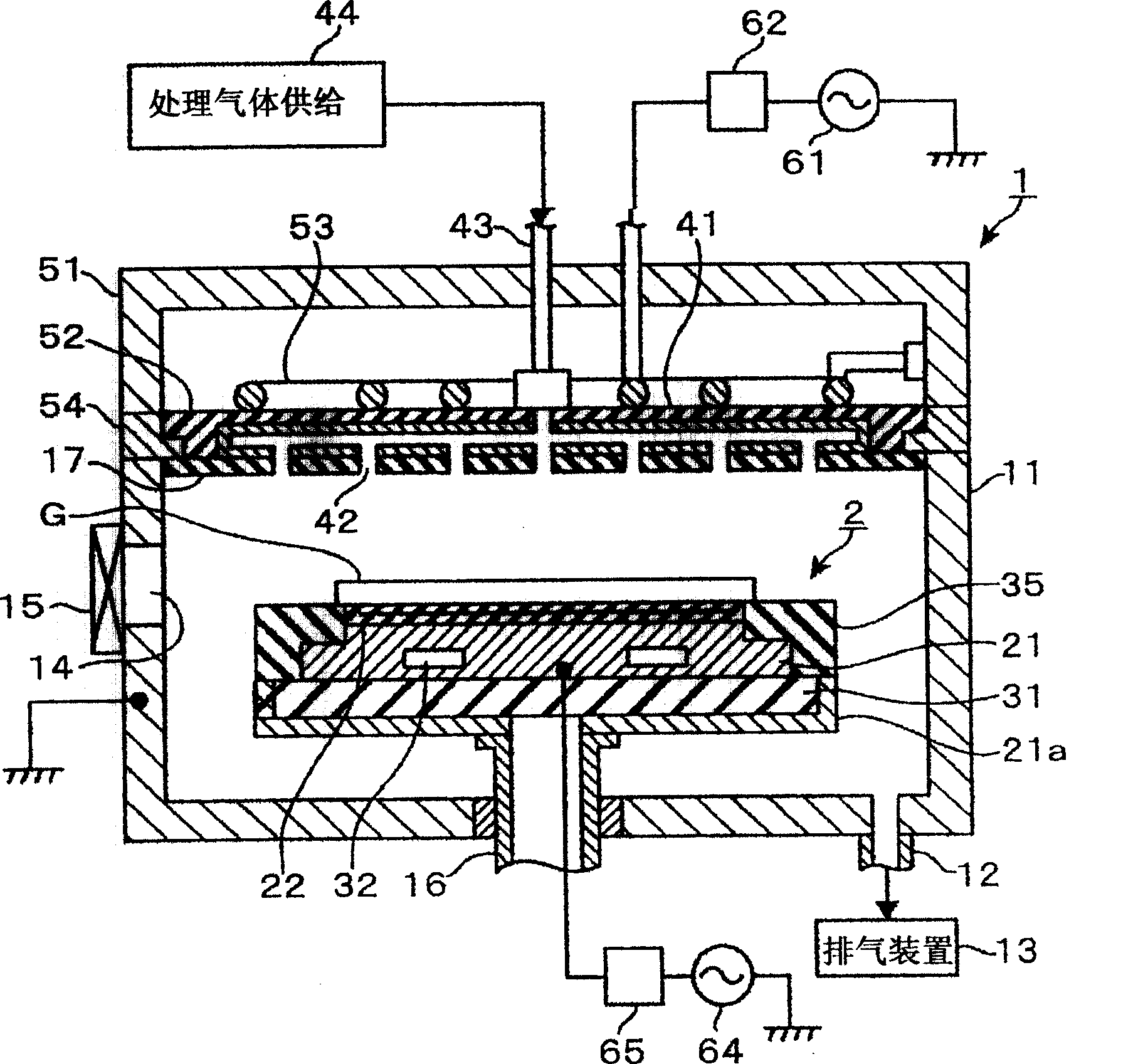

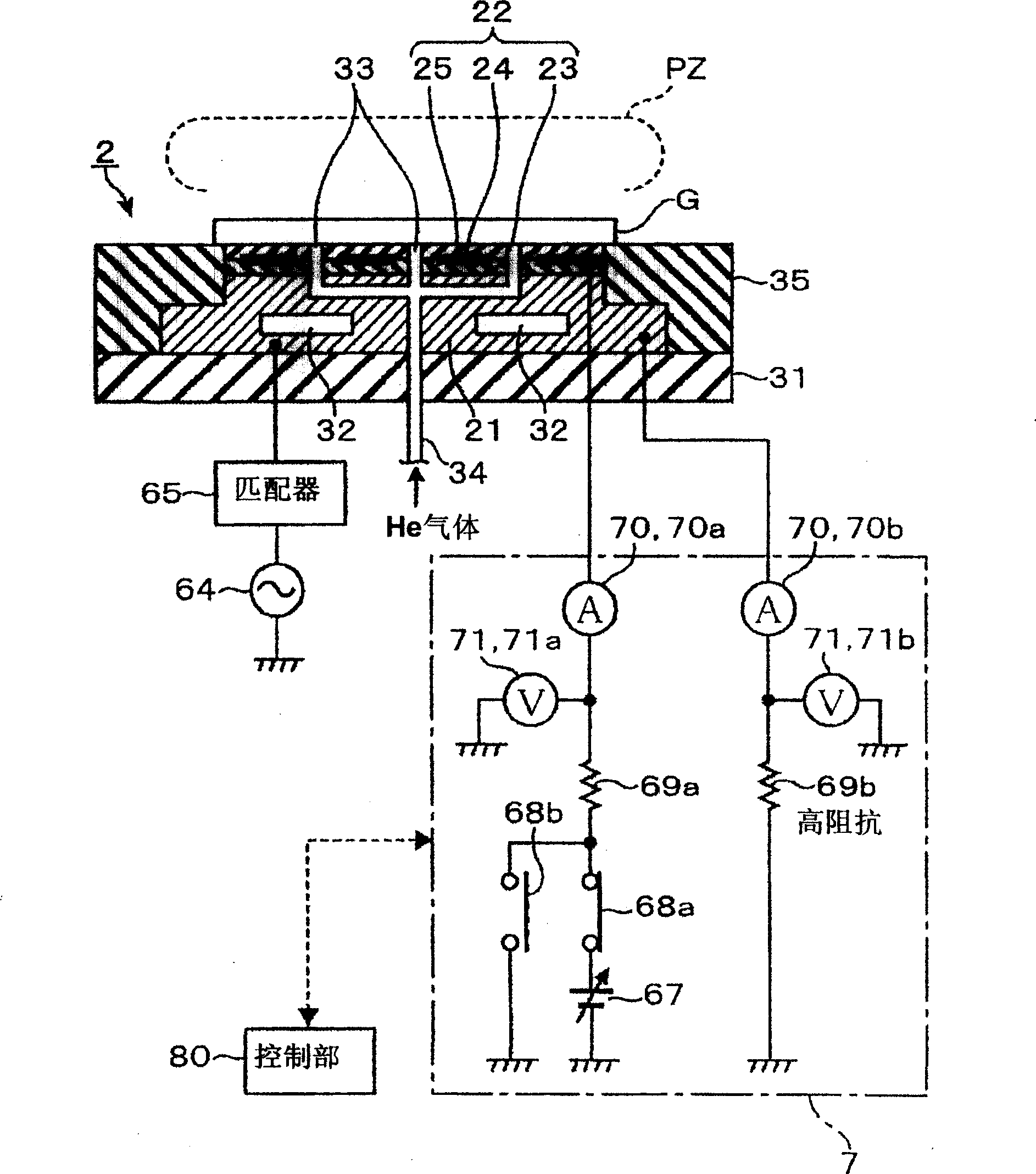

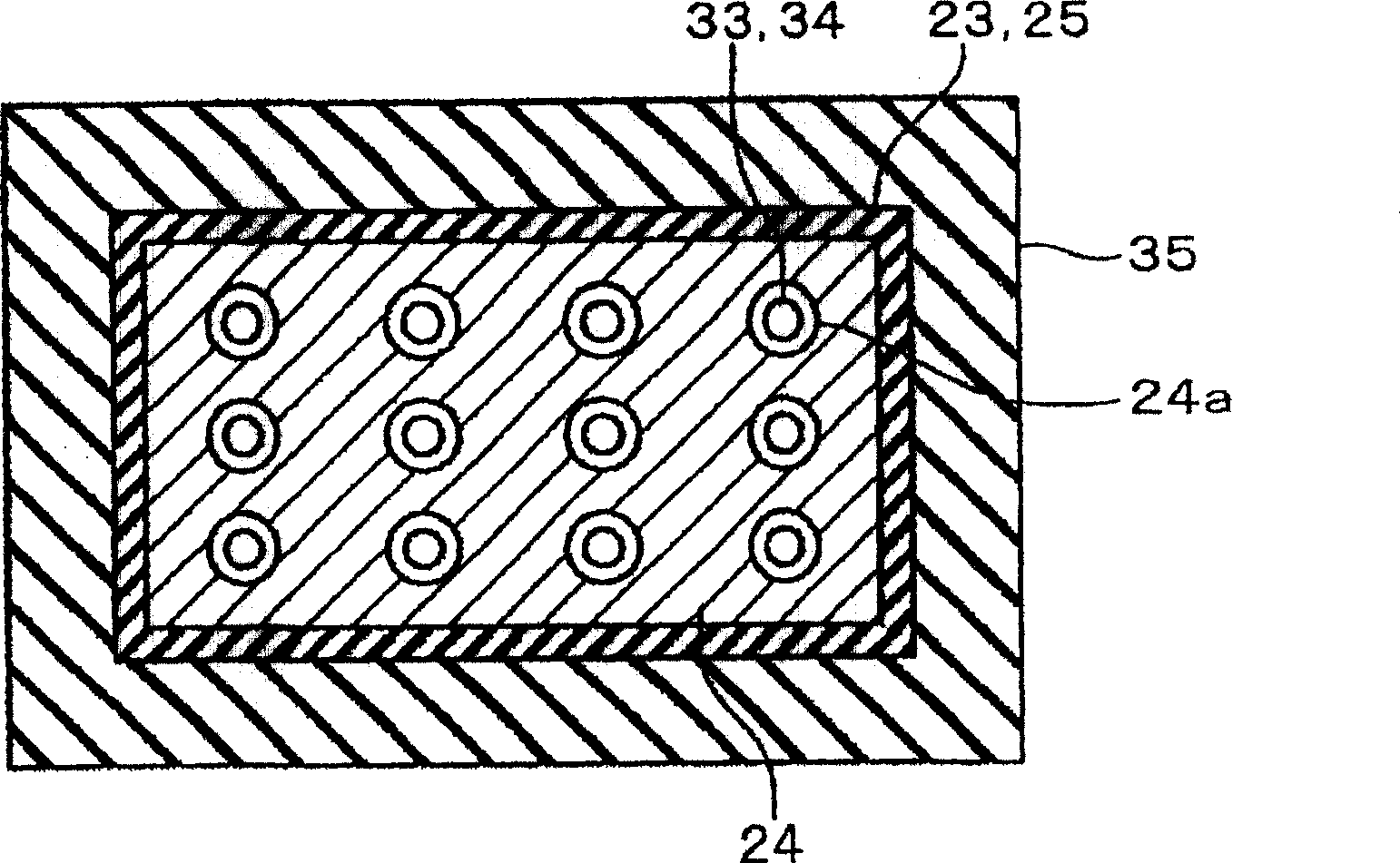

[0091] refer to Figure 1 ~ Figure 3 , an embodiment in which the vacuum processing apparatus of the present invention is applied to a plasma processing apparatus for etching a glass substrate for a liquid crystal display will be described. figure 1 is an example of the plasma processing apparatus 1 . For example, the plasma processing apparatus 1 has a processing container 11 composed of a vacuum container whose interior is a sealed space, an antenna container 51 provided on the upper part of the processing container 11, and a gas shower provided between the processing container 11 and the antenna container 51. The head 41 is the mounting table 2 arranged to face the gas shower head 41 at the center of the bottom surface of the processing chamber 11 .

[0092] A mounting table 2 and a hollow support 16 supporting the mounting table 2 and containing piping and the like are housed in the processing container 11 , and an exhaust device 13 including a vacuum pump and the like is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com