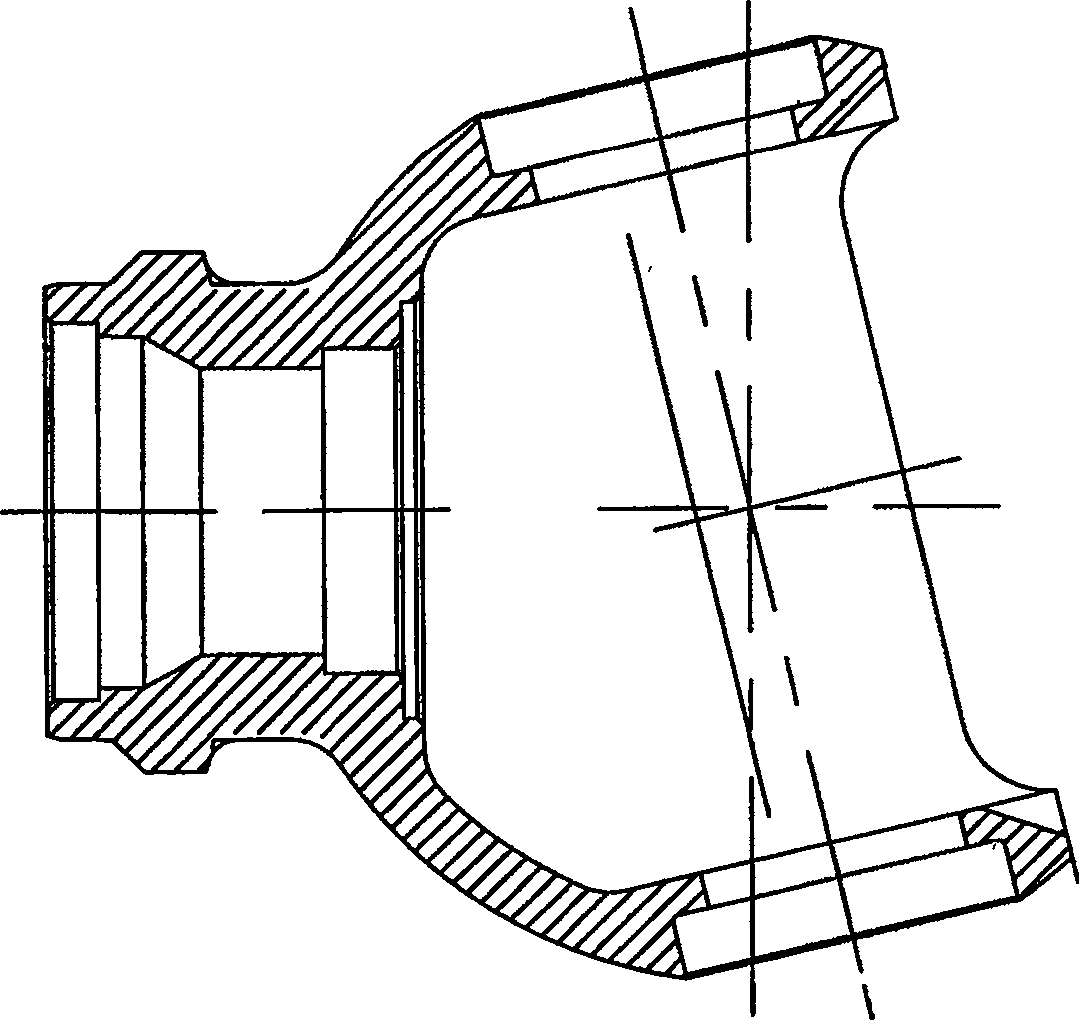

Welding clamp and welding process for axle housing assembly

A welding fixture and welding process technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult processing, high requirements for the concentricity of the two holes of the spherical support, and high requirements for dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

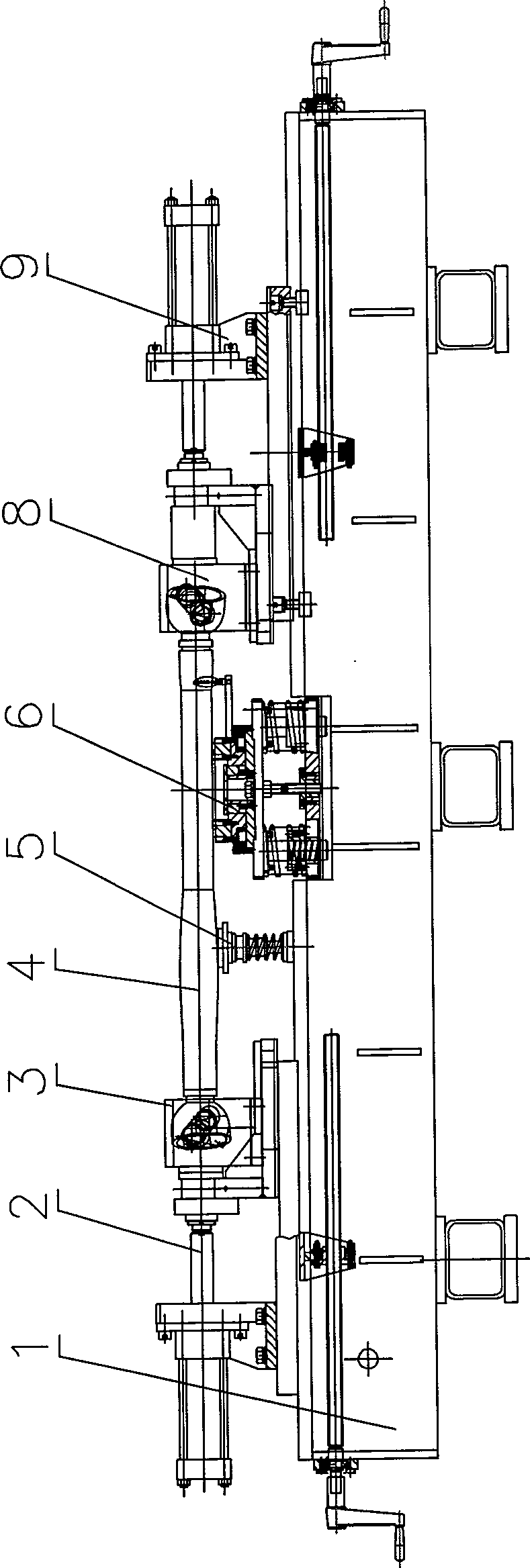

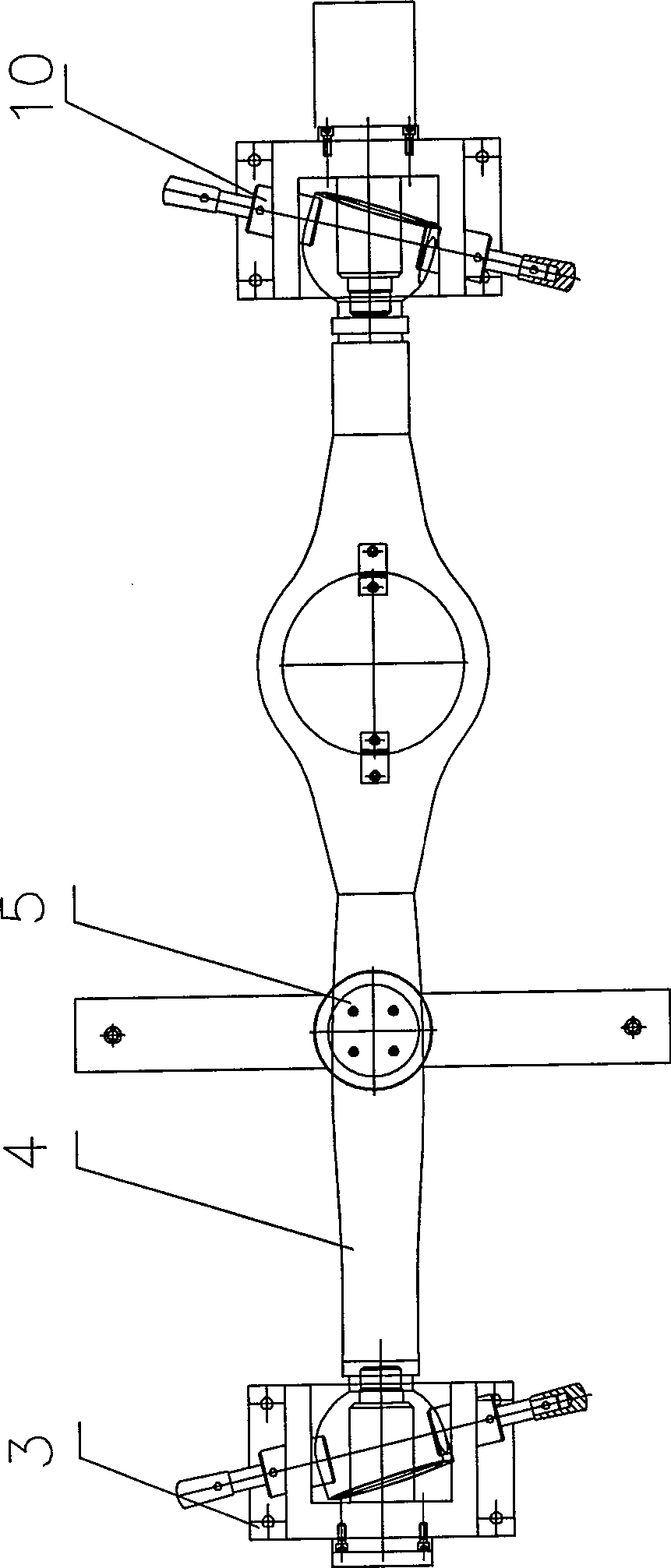

[0012] Embodiment 1: Taking the spherically supported front axle housing assembly as an example, the welding fixture is composed of bed 1, headstock 2, supporting left clamp body, axle housing body assembly balance support device 5, and axle housing body assembly center positioning device 6. The supporting right clamp is composed of a tailstock 9, a pin 10 and a control system. The headstock 2 and the tailstock 9 are respectively connected to the bed 1 through guide rails. The axle housing body assembly balance support device 5 and the axle housing body assembly center The positioning device 6 is connected with the bed 1 through the connecting key, the supporting left clamp body and the supporting right clamping body are respectively connected with the headstock 2 and the tailstock 9 through the connecting keys, and the supporting left clamping body and the supporting right clamping body are connected with the hydraulic power unit and the supporting right clamping body respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com