High polymer adjuvant adding device of disposal sanitary product production line

A technology for adding hygienic products and auxiliary materials, which is applied in the field of polymer auxiliary materials adding devices, can solve the problems that the amount of polymer auxiliary materials cannot be guaranteed to be consistent, the uniformity of polymer auxiliary materials cannot be guaranteed, and the operation, adjustment and maintenance are inconvenient. Simplified operation, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

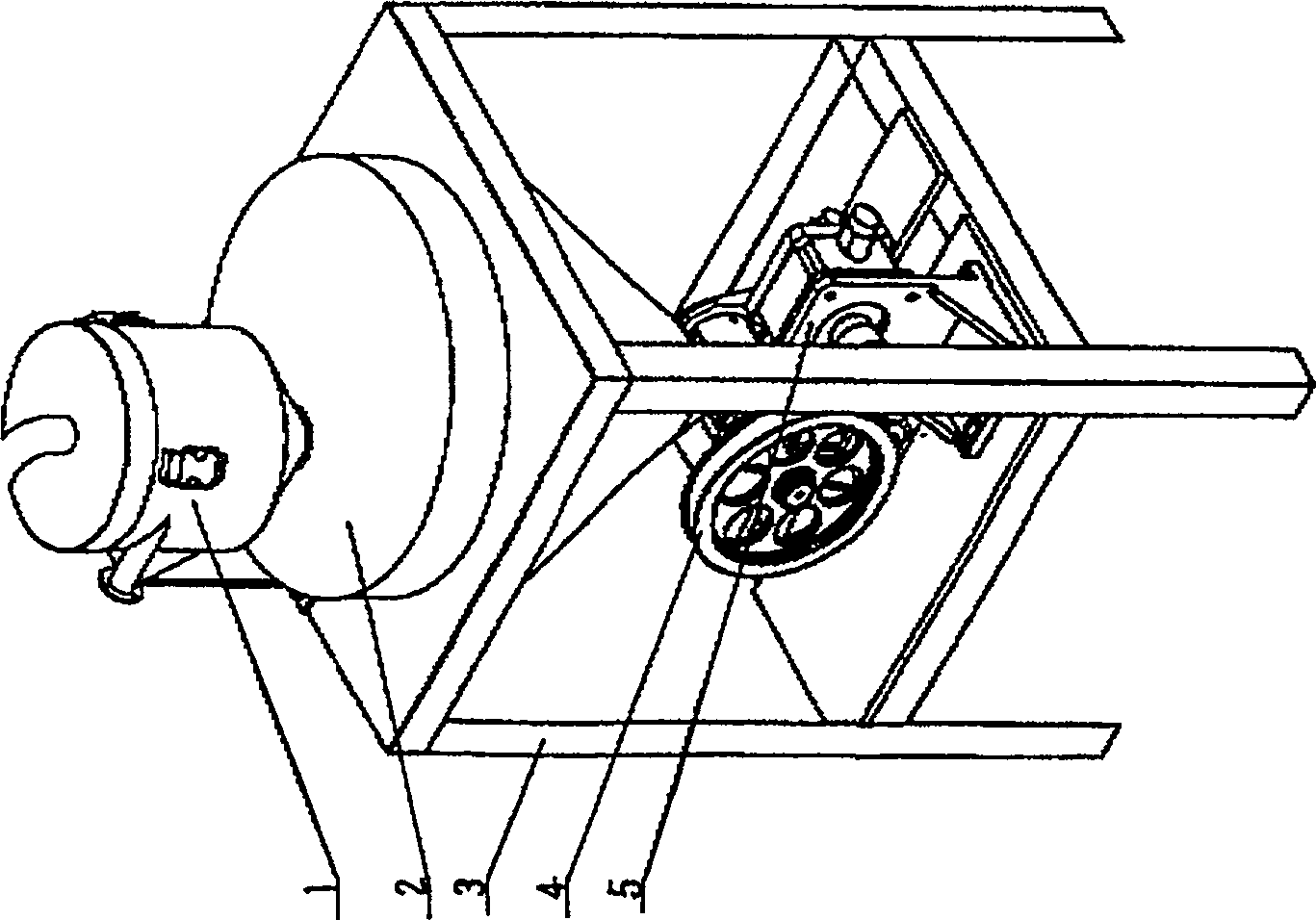

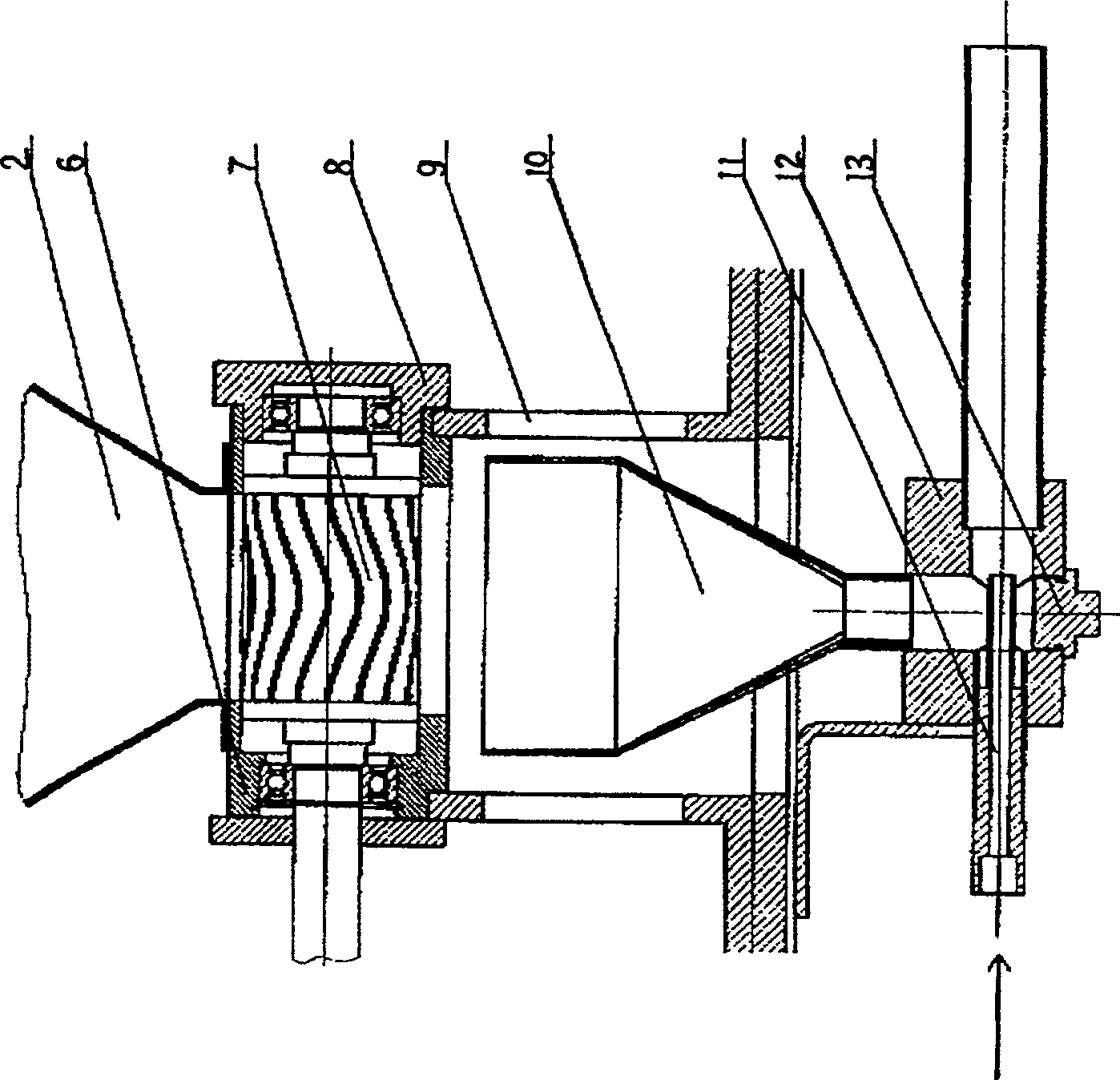

[0019] The polymer auxiliary material adding device on the disposable sanitary product production line includes a frame 3 , a suction hopper 1 , a storage hopper 2 , a feeding shaft 7 , a blowing hopper 10 and a blowing pipe 11 . The feeding shaft 7 is horizontally located at the outlet of the lower part of the storage hopper 2, the extended end of the feeding shaft 7 is connected to the motor 5 through the belt drive 4, the blowing hopper 10 is located below the feeding shaft 7, and the lower end of the blowing hopper 10 is connected to the horizontal blowing pipe 11, see figure 1 .

[0020] The outer surface of the feeding shaft 7 corresponding to the outlet of the storage hopper 2 is evenly distributed with "herringbone" grooves, and the "herringbone" groove section of the feeding shaft 7 is installed in the feeding shaft seat 6 through a bearing, and the feeding shaft seat 6 plays a sealing role on the feeding shaft 7, and the gland 8 seals the two ends of the "herringbon...

Embodiment 2

[0024] The blowing block 12 is fixedly installed on the frame 3, the blowing block 12 is provided with a cross through hole, the upper port of the vertical through hole is connected to the discharge port of the blowing hopper 10, and the lower port is equipped with a screw plug 13; the horizontal through hole It is a horizontal blowing tube, the diameter of the inlet end on one side is 10-15mm, and the diameter of the outlet end is 30-45mm; the inlet end of the blowing tube is connected to the air supply pipe of the air compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com