Needle-thread guiding out device of sewing machine

A technology for exporting devices and sewing machines, which is applied in the direction of sewing machine thread take-up devices, sewing machine components, sewing equipment, etc., and can solve the problems of unavoidable half-moon bulge sewing quality reduction, reduction, and sewing quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

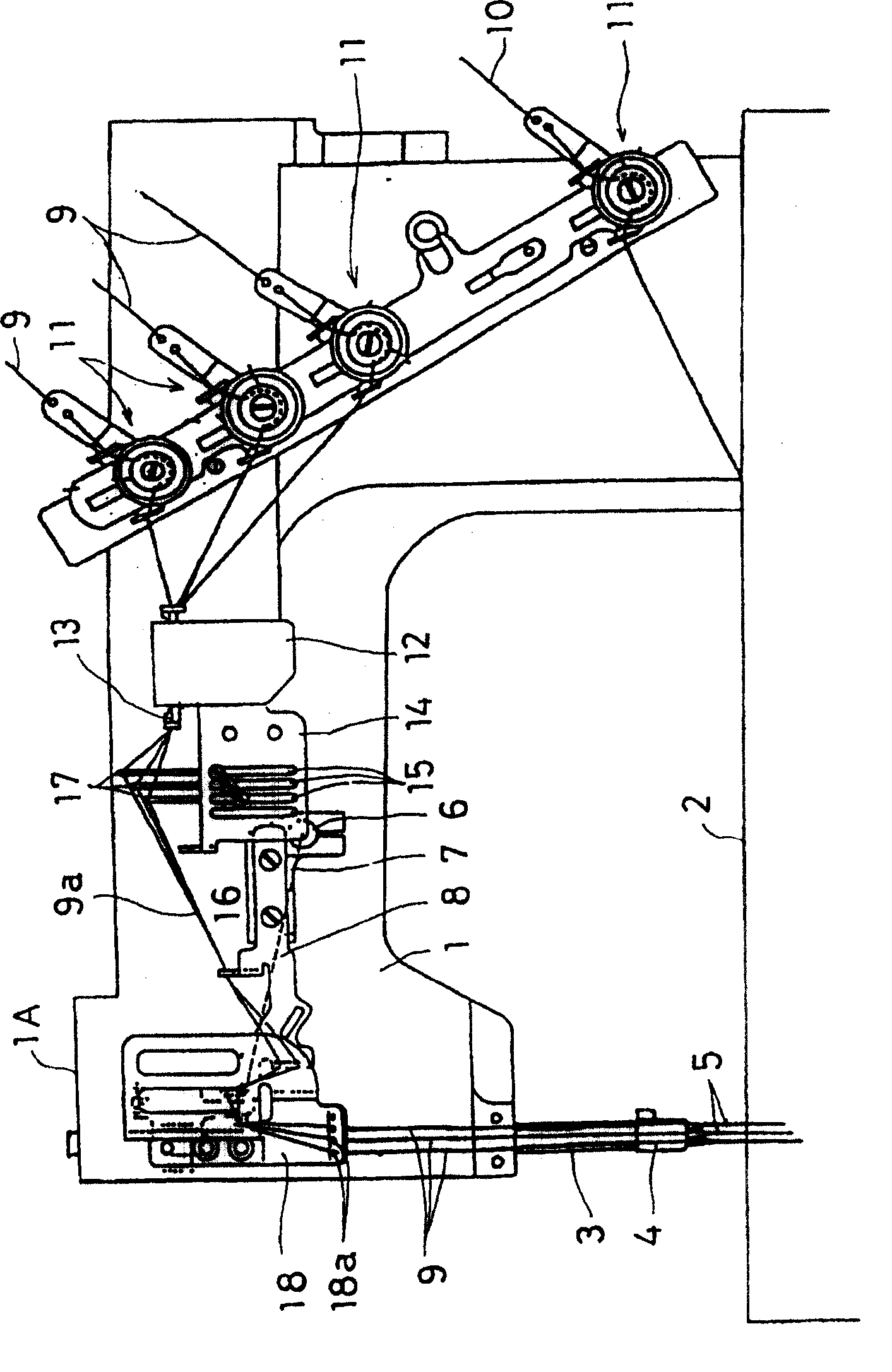

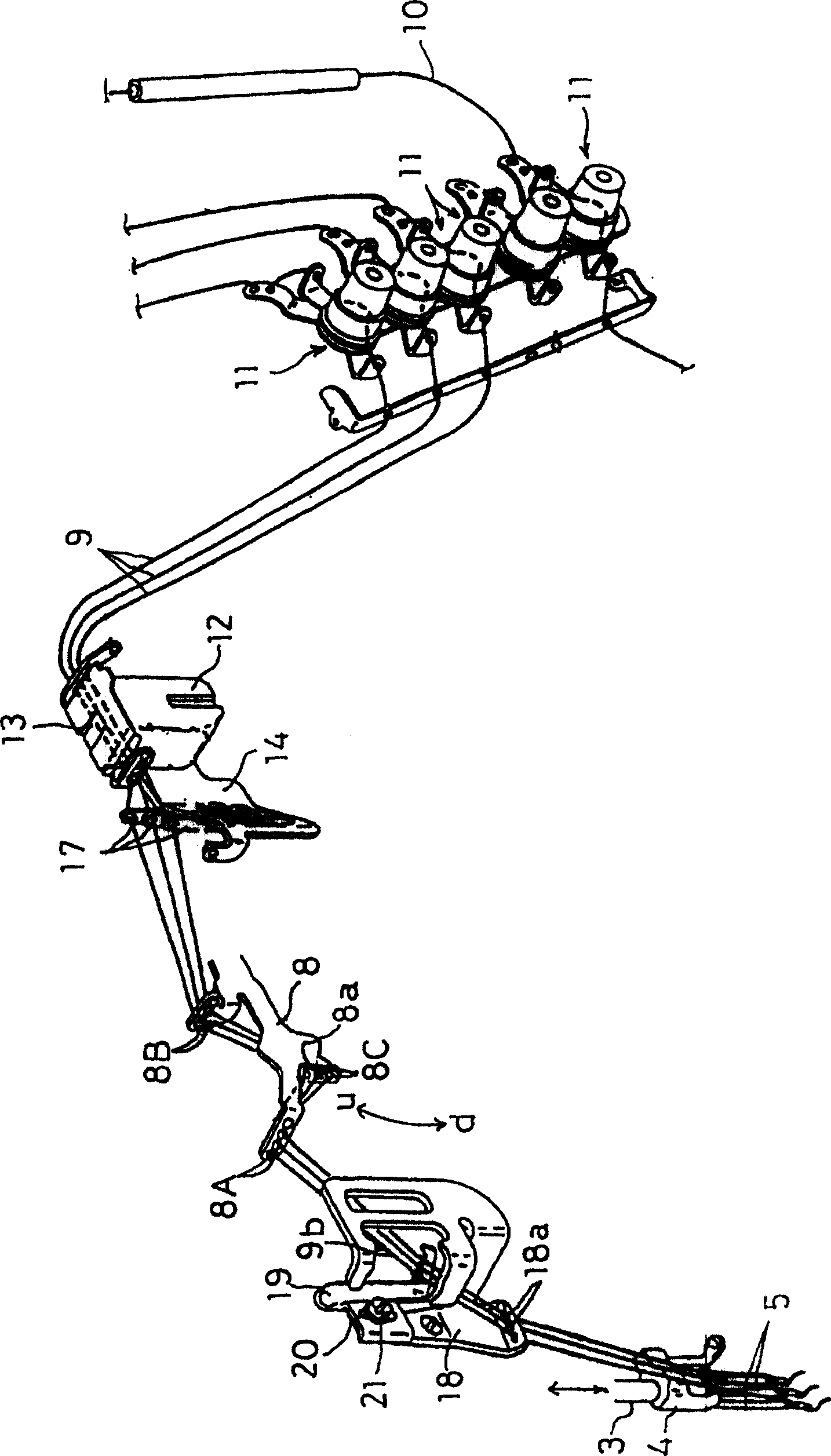

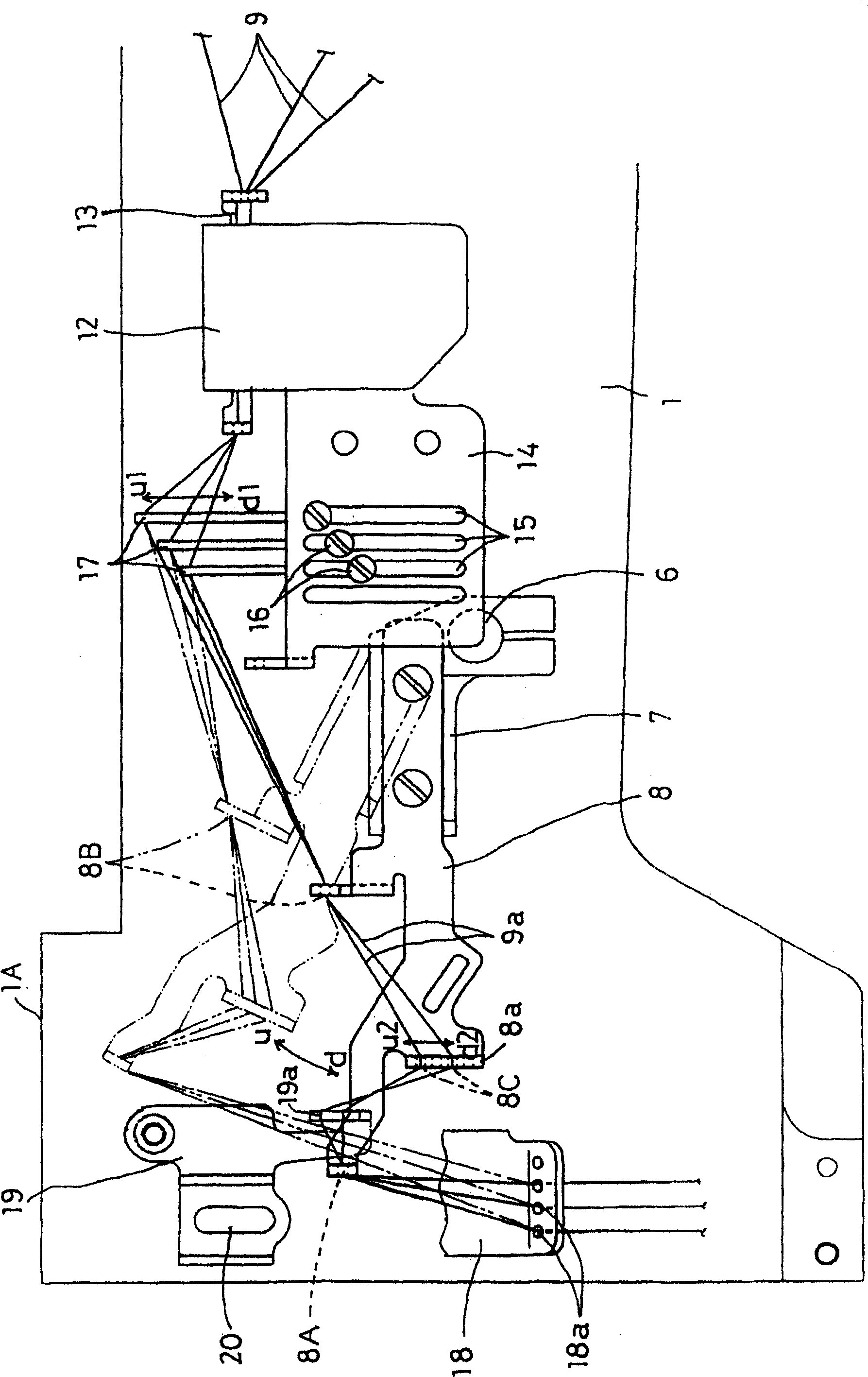

[0027] figure 1 It is an overall front view of a 3-needle flatbed interlock sewing machine using the present invention, figure 2 It is a perspective view showing the configuration of the main part of the needle thread lead-out device in the above-mentioned 3-needle flat chain sewing machine, image 3 yes figure 2 The enlarged front view of the main part. In each of these figures, 1 is a sewing machine arm, 2 is a sewing machine bottom plate, and the left end of the sewing machine arm 1 is supported by a known crank mechanism and a drive spindle inserted and supported in the sewing machine arm 1 (not shown). Shown) interlocking, the needle bar 3 that can reciprocate in the up and down direction, and the gray cloth pressing mechanism is set adjacent to the needle bar 3 simultaneously (because it is well known, the detailed description is omitted).

[0028] Three needles 5 are installed on the lower end of the above-mentioned needle bar 3 through the needle clamp 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com