Component, chamber device and transfer device having the component

A transfer device and component technology, which is applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve the problems of expensive and bellows, and achieve simple manufacturing, good sealing effect, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

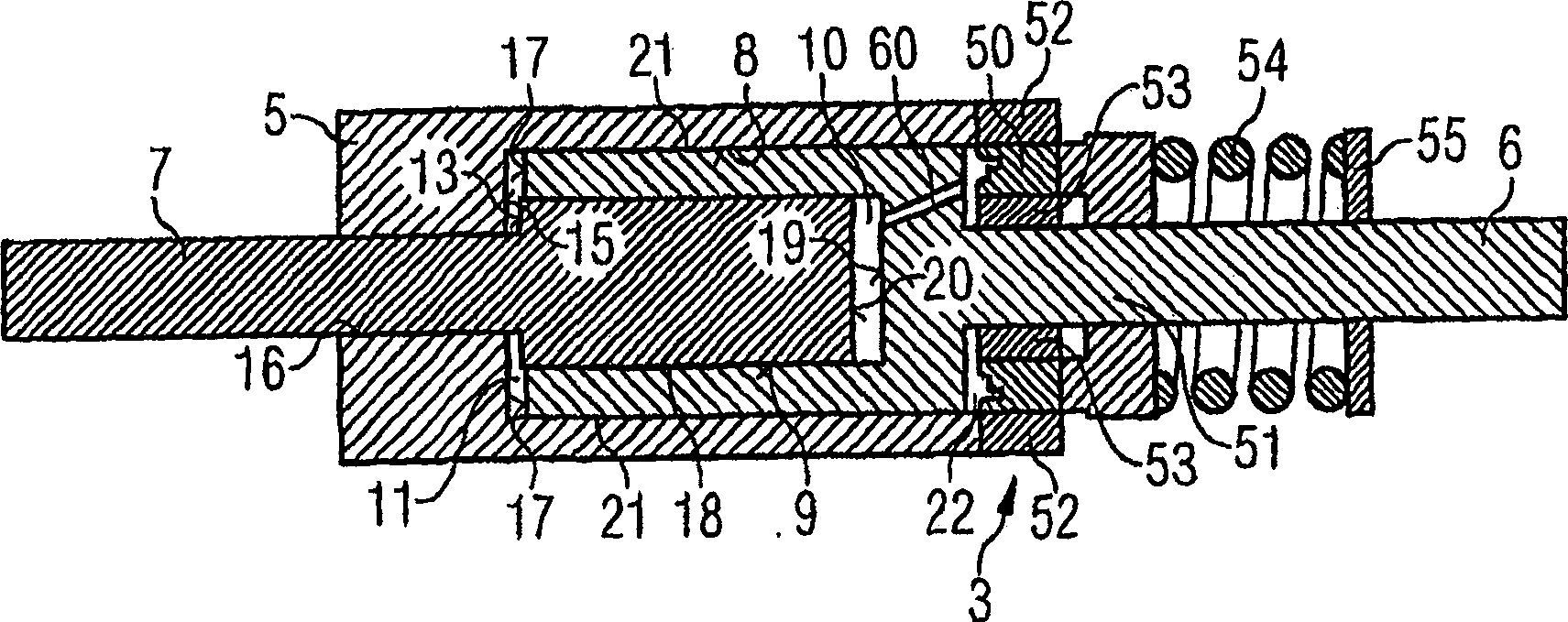

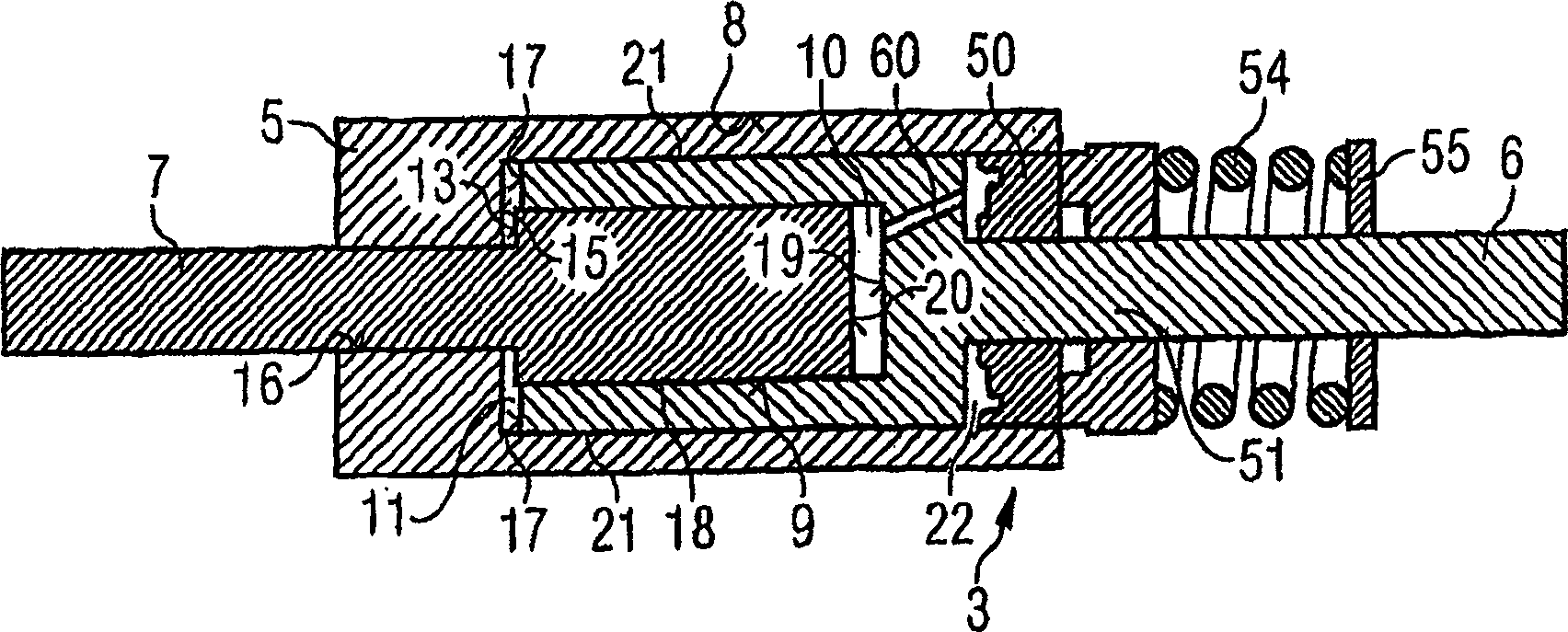

[0026] Components with the same structure and function are denoted by the same reference numerals in the figures.

[0027] An injection valve 1 has an actuator 2 which is functionally connected via a transmission device 3 to a nozzle needle 4 . The actuator 2 is preferably formed as a piezoelectric actuator. However, it can be another actuator that generates a stroke. The transfer device 3 preferably converts the deflection of the actuator 2 in the direction of the nozzle needle 4 such that a deflection of the actuator 2 in the direction of the nozzle needle 4 is transmitted as an amplified deflection of the nozzle needle 4 . Furthermore, the transfer device preferably also compensates for temperature-induced changes in the length of the actuator. Depending on its position, the nozzle needle closes or releases a nozzle 41 in the injector 1 and thus controls the fuel metering.

[0028] According to the exemplary embodiment, the transmission device 3 can also transmit a defle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com