Organic-inorganic hybrid solid super strong alkali and preparation method thereof

A solid super base and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve limited applications, complex processes, equipment, and preparation steps cumbersome and other problems, to achieve the effect of high selectivity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

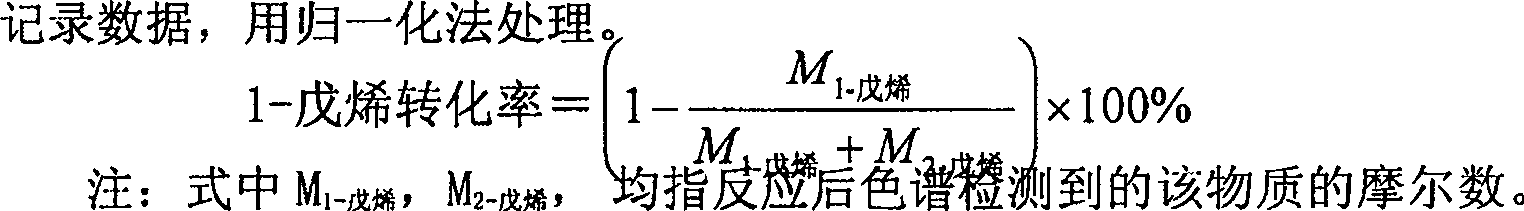

Image

Examples

Embodiment 1

[0026] in N 2 Quickly cut 0.05g of metal potassium from the stream, add it to a three-necked bottle containing 10ml of n-hexane, heat and stir to 75°C under the protection of high-purity nitrogen, and keep it for about 1h. At this time, K is in hexane Disperses as tiny blue particles. Add 0.95g of hydrotalcite activated in a nitrogen stream at 500°C to the hexane with K dispersed, the activation time is 2 hours, stir, and evaporate the excess n-hexane at 80°C to form a blue powder K n R / MgAl(O) samples. in N 2 Add 20ml of benzaldehyde solution that has been purified and dried beforehand under the protection of Stir and react at 140°C. After 30 minutes, the product is taken out for analysis. The yield of benzyl benzoate is 63.5%, and the selectivity is 97.4%.

Embodiment 2

[0028] in N 2 Quickly cut 0.1g of metal potassium from the stream, add it to a three-necked bottle containing 10ml of n-hexane, heat and stir to 75°C under the protection of high-purity nitrogen, and keep it for about 1h. At this time, K is in hexane Disperses as tiny blue particles. Add 0.9g of hydrotalcite activated in a nitrogen stream at 500°C to the hexane dispersed with K, the activation time is 2 hours, stir, and evaporate excess n-hexane at 80°C to produce blue powder K n R / MgAl(O) samples. in N 2 Add 20ml of benzaldehyde solution that has been purified and dried beforehand under the protection of Stir and react at 140°C. After 30 minutes, the product is taken out for analysis. The yield of benzyl benzoate is 75%, and the selectivity is 99.9%.

Embodiment 3

[0030] in N 2 Quickly cut 0.2g of metered metal potassium from the stream, add it to a three-necked bottle containing 10ml of n-hexane, heat and stir to 75°C under the protection of high-purity nitrogen, and keep it for about 1h. At this time, K is in hexane Disperses as tiny blue particles. Add 0.8 g of K dispersed in hexane and activate (2h) the hydrotalcite at 773K in a nitrogen stream. Stir and steam excess n-hexane at 80°C to produce blue powder K n R / MgAl(O) samples. in N 2 Add 20ml of benzaldehyde solution that has been purified and dried beforehand under the protection of Stir and react at 140°C. After 30 minutes, the product is taken out for analysis. The yield of benzyl benzoate is 99.8%, and the selectivity is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com