Cleaning-free smoke purifier

An oil fume purifier and no-cleaning technology, applied in the fields of oil fume removal, chemical instruments and methods, and household heating, etc., can solve the problems of easy-to-stick oil pollution, poor economy and practicability, and secondary pollution, and achieve no secondary pollution. secondary pollution, significant technological advancement, and the effect of removing oily fume odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

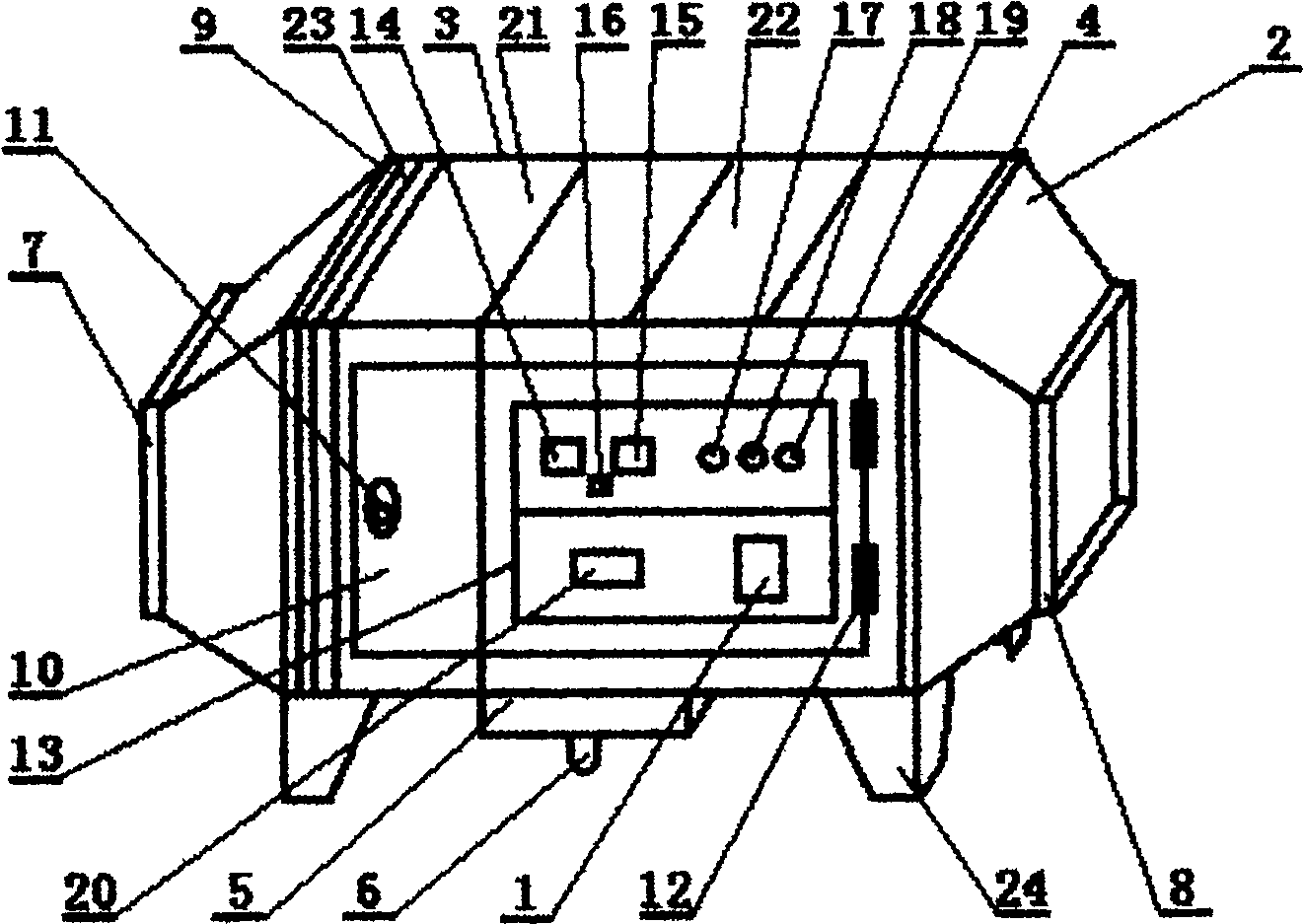

[0019] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

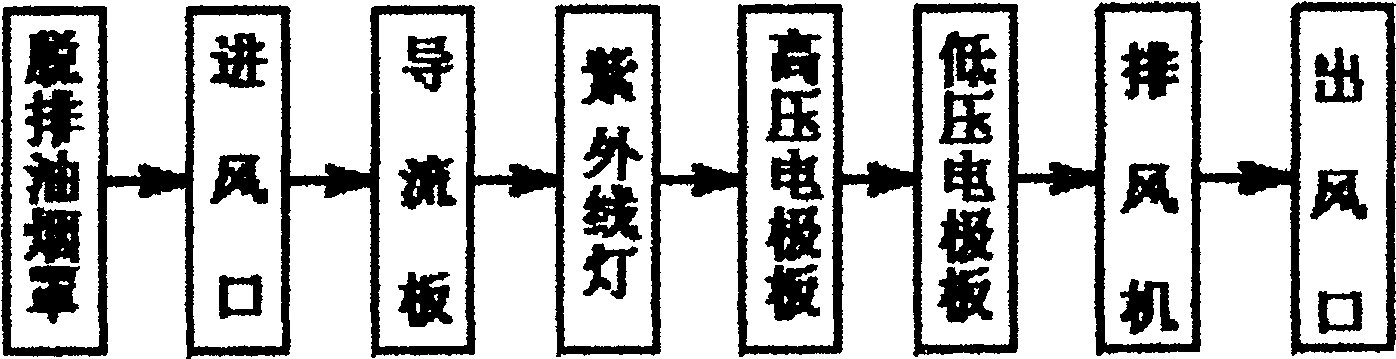

[0020] exist figure 1 and figure 2 Among them, the no-clean oil fume purifier of the present invention is mainly composed of a distribution box 1, an outer shell 2, an inner tank 3, an oil screen 4, an oil receiving tray 5 and a valve 6. Among them, the distribution box 1 is equipped with a fully sealed, modular high-frequency, high-voltage pulse dedicated power supply, on which are equipped with relays, delayers, transformers, overvoltage, overcurrent protection devices, and special control buttons for adjusting current and frequency Switch; the shell 2 is made of stainless steel plate, which is a closed part with an opening door 10, and the left and right ends are respectively provided with an air inlet flange 7 and an air outlet flange 8, through which the air inlet flange 7 and the air outlet flange 8 are connected The exhaust fume hood p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com