Linear slide rail with detachable oil tank

A technology of linear slide rails and fuel tanks, which is applied to manufacturing tools, bearings for linear motion, large fixed members, etc., can solve the problems of troublesome work of adding fuel, stoppage of mechanism operation, limited fuel tank, etc., to improve market competitiveness and simplify Work procedure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

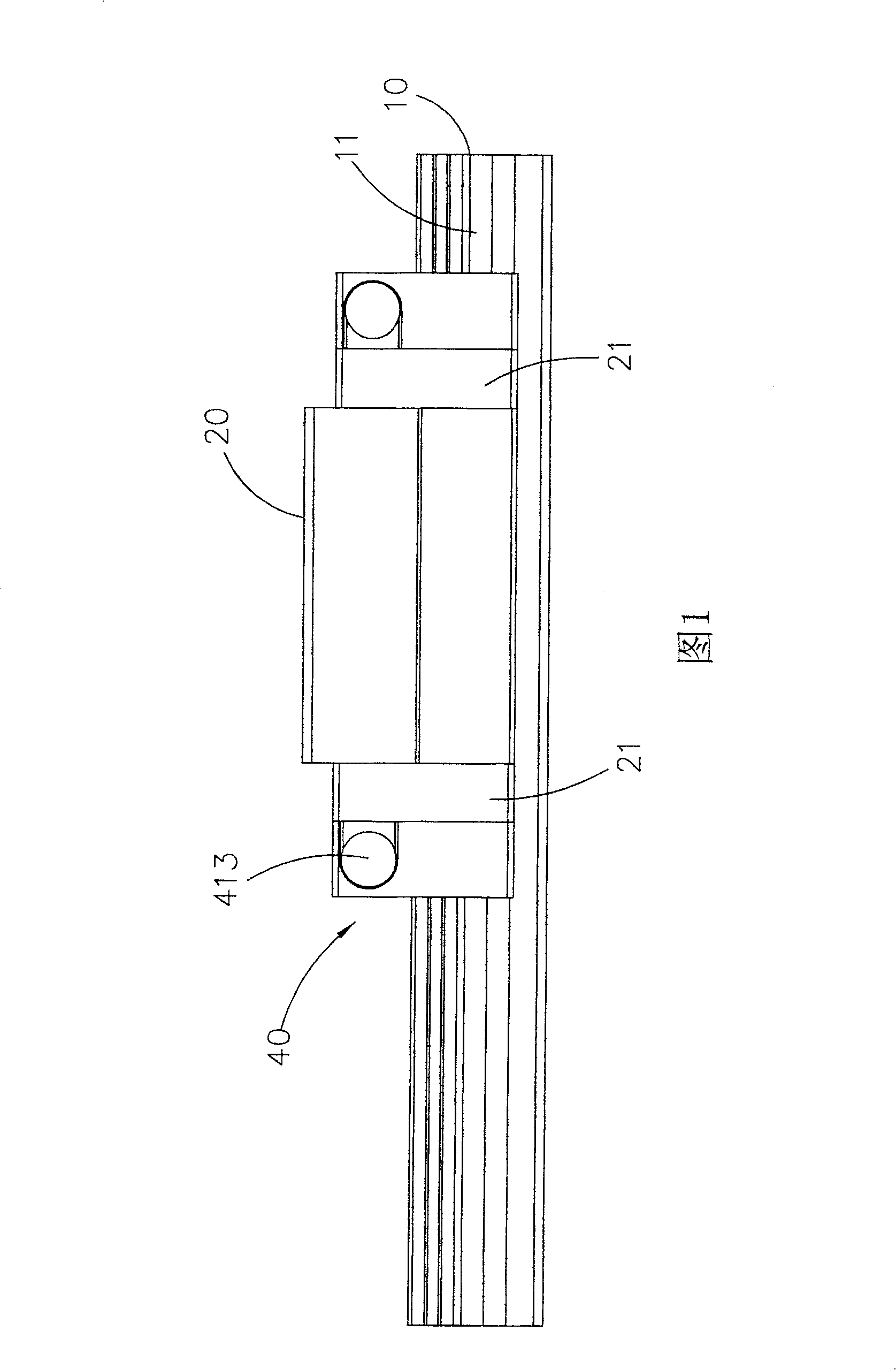

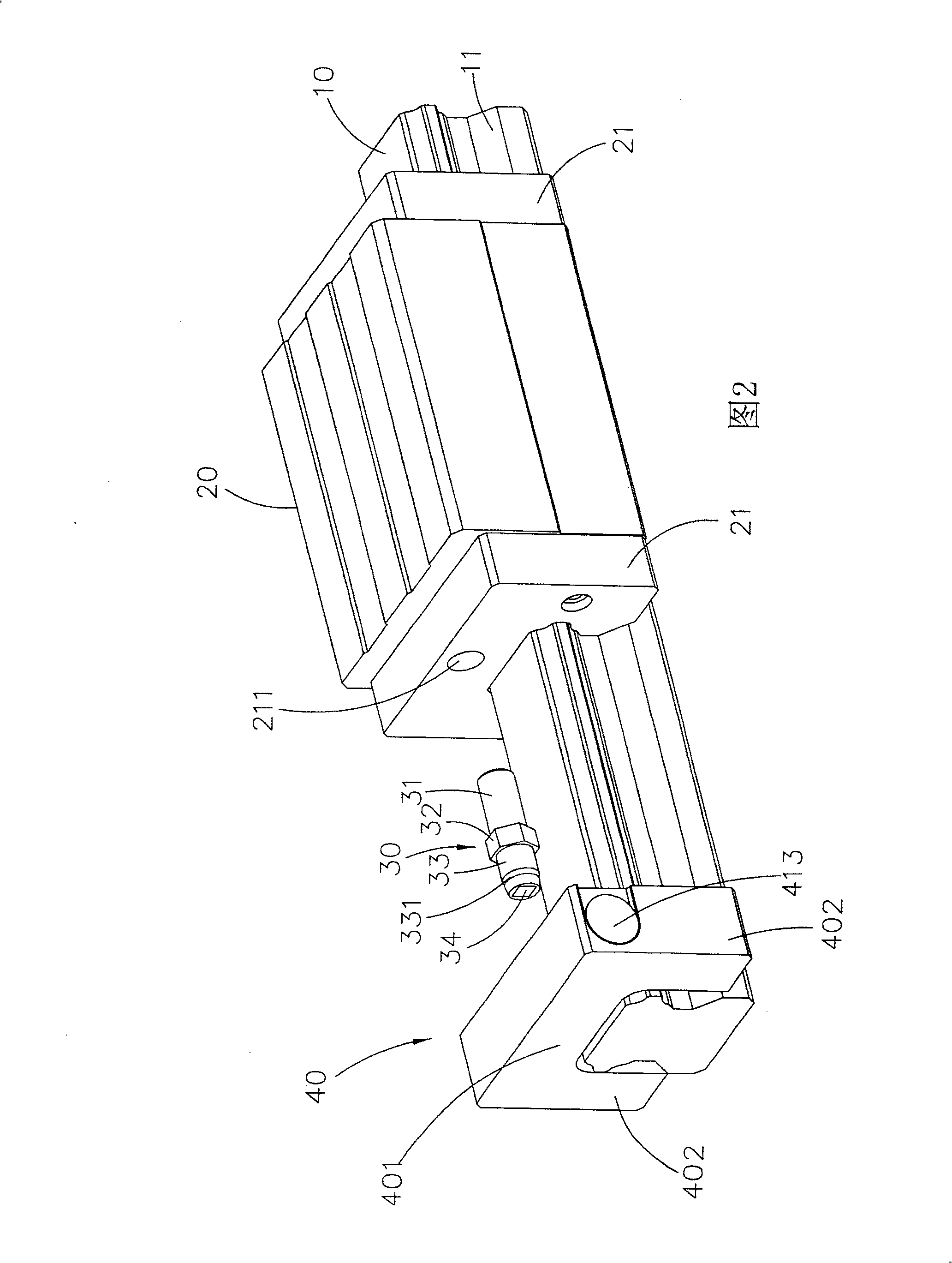

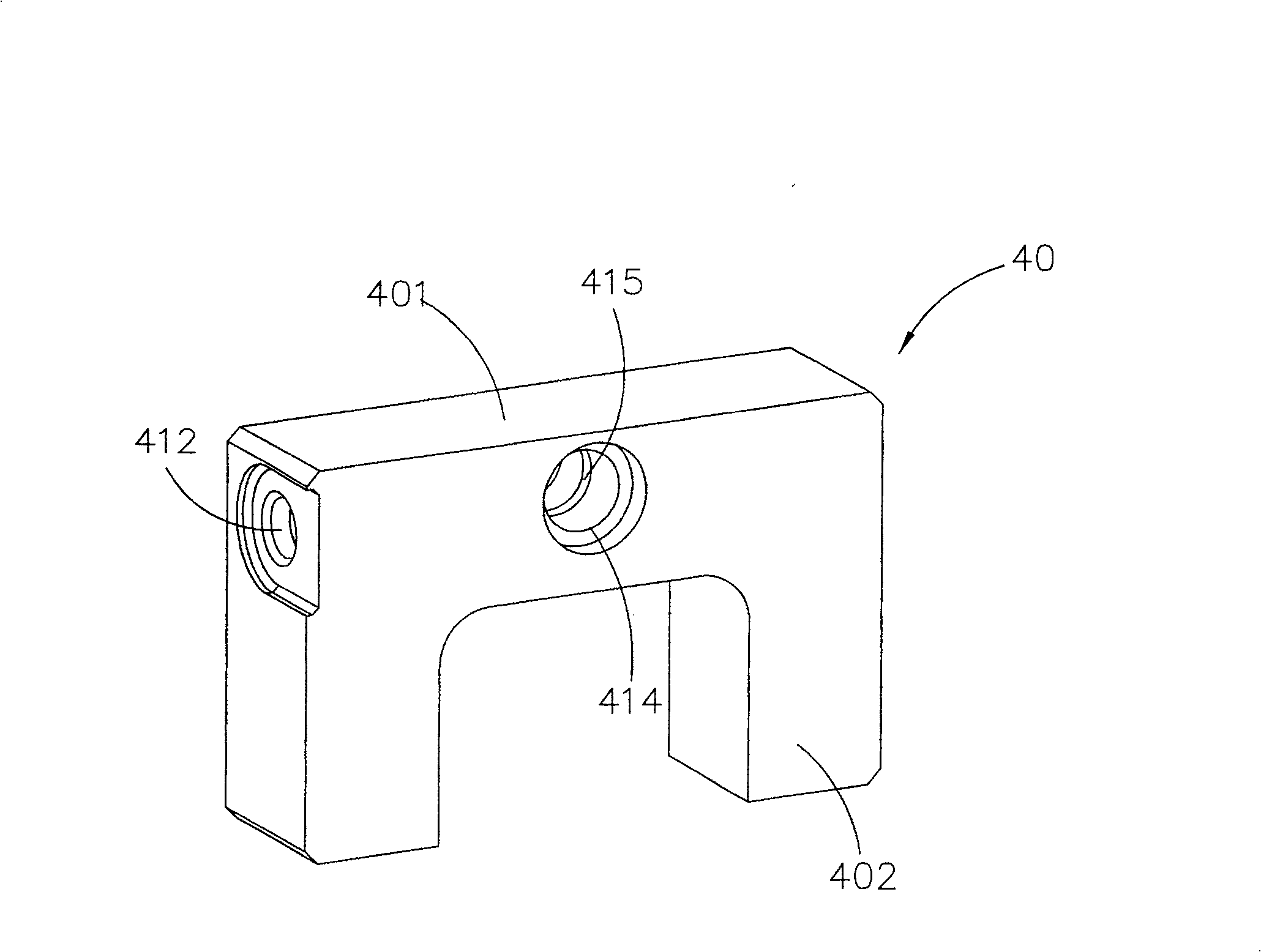

[0042] Relating to the present invention to achieve the above-mentioned purpose, the highly technical thinking and means adopted, hereby enumerate a preferred embodiment and cooperate with each drawing in detail as follows, believe that the purpose, characteristics and other advantages of the invention of the present case should be obtained by it For in-depth and specific understanding, please refer to Figure 1-7 shown.

[0043] The linear slide rail with removable fuel tank of the present invention comprises a slide rail 10, a slider 20, two connectors 30 and two fuel tanks 40, and its structure is described in detail as follows:

[0044] The slide rail 10 is provided with concave-convex track structures 11 on both sides.

[0045] The slider 20 is equipped with end caps 21 at both ends, and the slider 20 and the end caps 21 are all arranged on the track structure 11 of the slide rail 10, and the end surface of the end cap 21 is provided with a threaded connection. seat 211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com