Underground sewer repairing method

A technology for sewage pipelines and waterstops, which is used in the repair construction and treatment of large-diameter underground sewage pipeline interface cracks and leakage, and the repair construction of underground sewage pipelines. It can solve the problems of large-diameter pipeline cracks, leakage, etc. Guaranteed improvement, strong adaptability and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

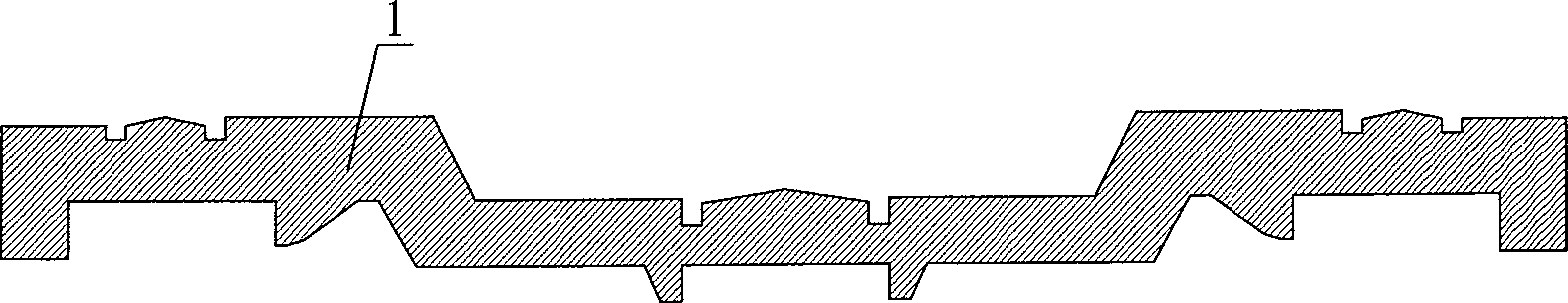

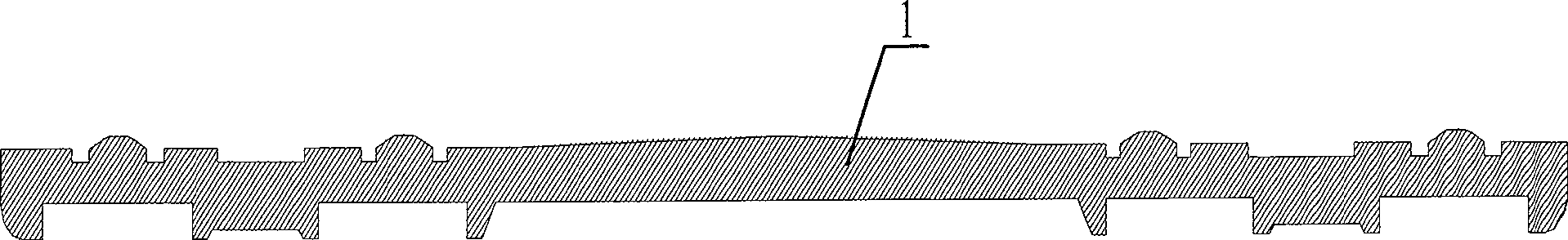

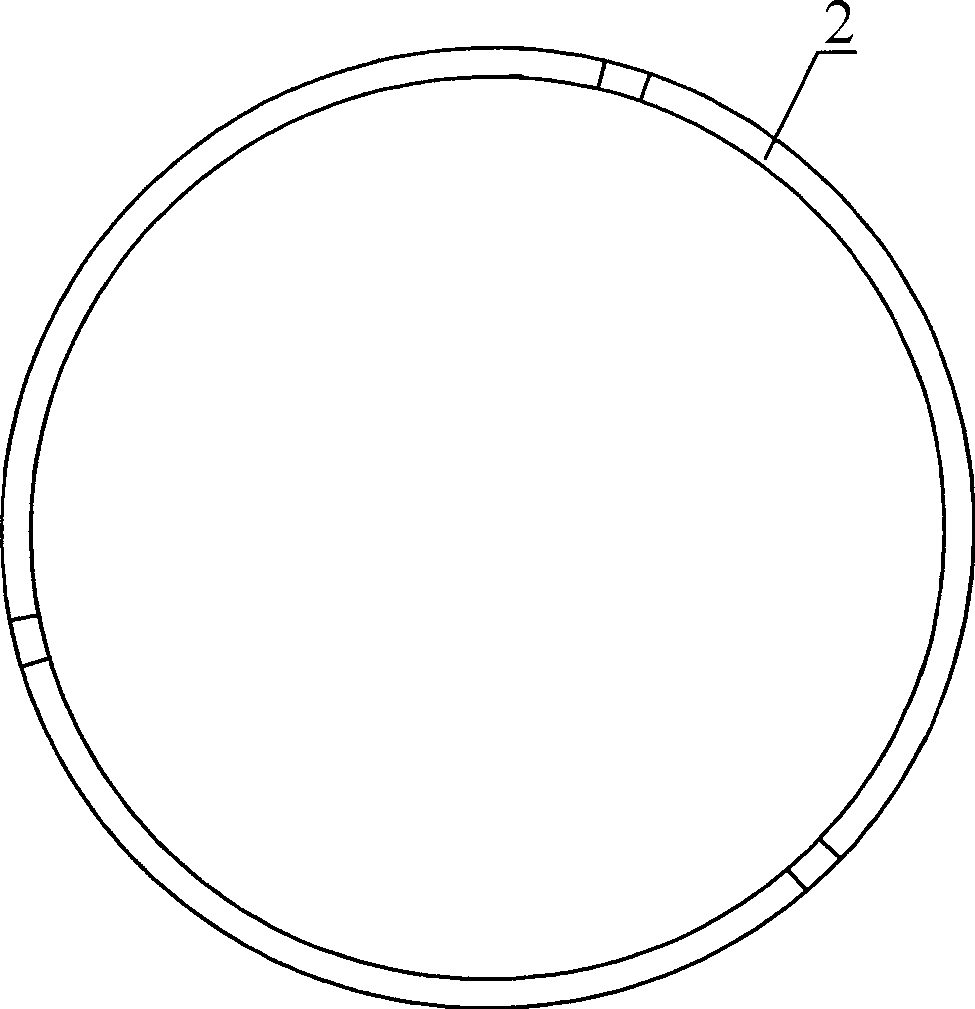

[0023] Such as Figure 1 ~ Figure 4 As shown, the water-stop belt 1, the inner expansion ring 2 and the locking connection mechanism are provided. The water-stop belt 1 has an annular belt-like structure. The water-stop belt 1 is attached to the junction of two large-diameter underground sewage pipelines. One surface of 1 is attached to the inner circular surface of the pipe, and the surface where the waterstop 1 is attached to the connecting pipe is provided with a sealing groove; the other side of the waterstop 1 is matched with the outer circular surface of the inner expansion ring 2 and stops The matching surface of the hose 1 and the inner expansion ring 2 is provided with grooves. Correspondingly, the mating surface of the inner expansion ring is provided with a convex channel; the inner expansion ring 2 is connected by at least two arc-shaped inner expansion rings. As a result, the ends of the two adjacent segments of the inner expansion ring body are connected by a snap co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com