Inspection method of high-speed rail contact wire guide height and pull-out value based on airborne lidar

A technology of airborne laser radar and laser radar, which is applied in the direction of using optical devices, radio wave measurement systems, instruments, etc., to achieve the effect of expanding the detection time range, improving accuracy, and releasing line capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

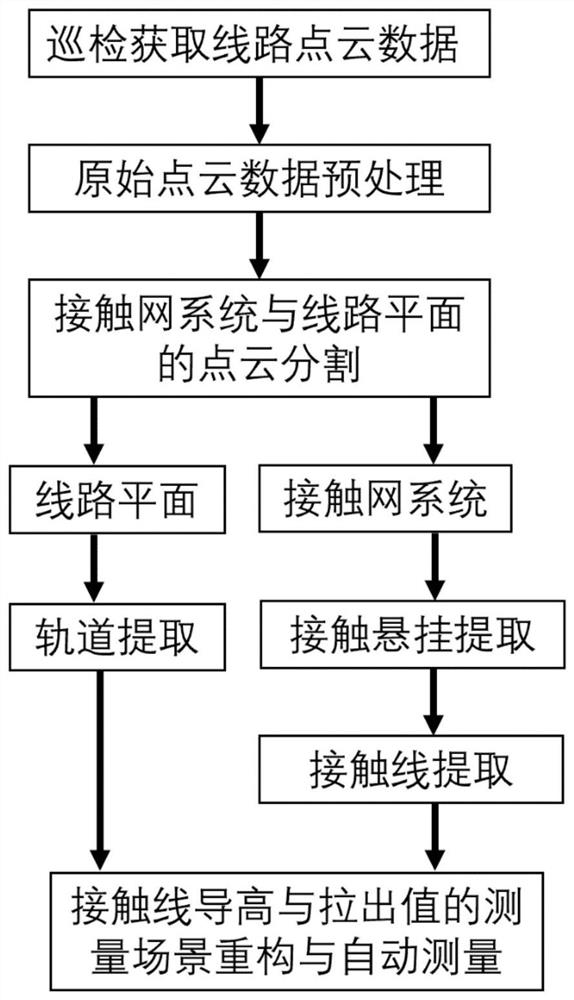

[0047] like figure 1 As shown, an airborne lidar-based high-speed rail contact line conduction height and pull-out value inspection method includes the following steps:

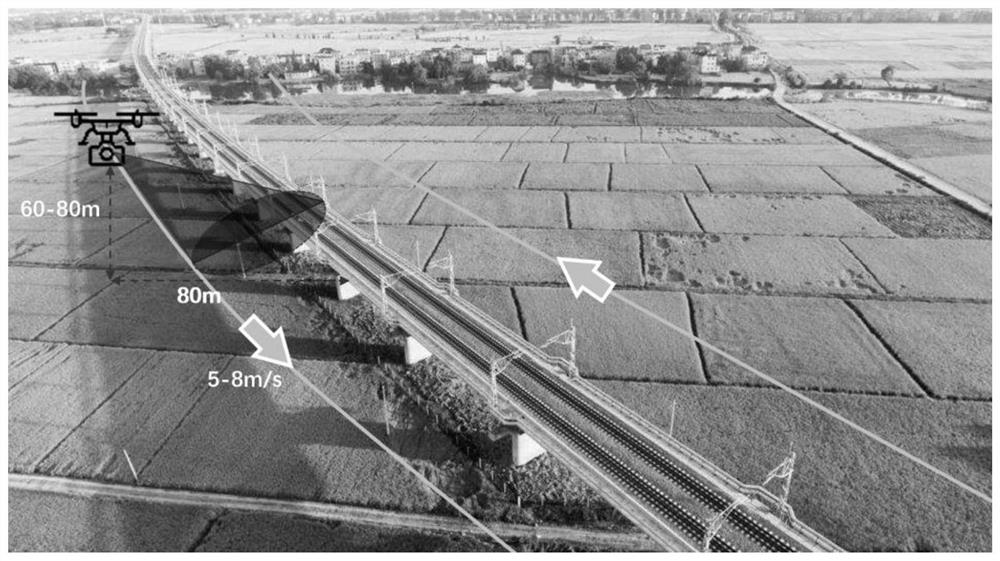

[0048] Step 1: Use the drone equipped with lidar to inspect along the upper side of the railway line to obtain the original point cloud data of the line;

[0049] Step 2: Preprocessing the original point cloud data;

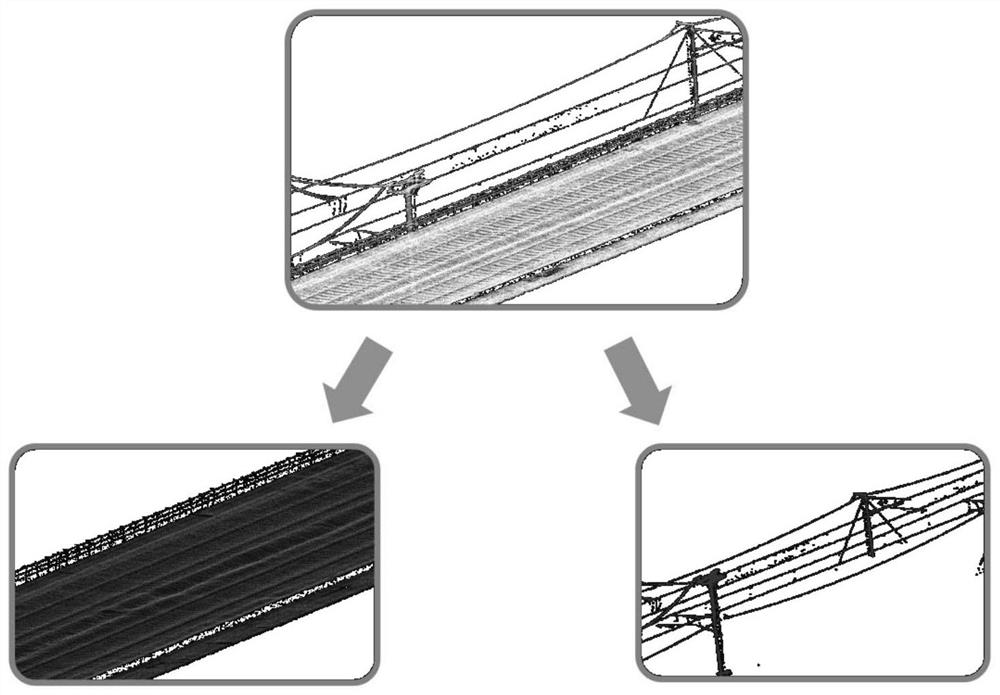

[0050] Step 3: Use random sampling consensus algorithm to segment and extract the processed original point cloud data to obtain catenary system point cloud and line plane point cloud;

[0051] Step 4: Extract the track in the line plane point cloud;

[0052] Step 5: Segment the point cloud of the contact suspension and pillar support in the catenary system;

[0053] Step 6: Extract the contact line in the contact suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com