Production process of five-ester droplet

A production method and technology for ester dropping pills, applied in the production field of pentaester dropping pills, can solve the problems of increasing interfacial tension, difference in pellet weight, small interfacial tension, etc., and achieve control of pellet roundness, control of pellet weight difference and , The effect of improving the rate of qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

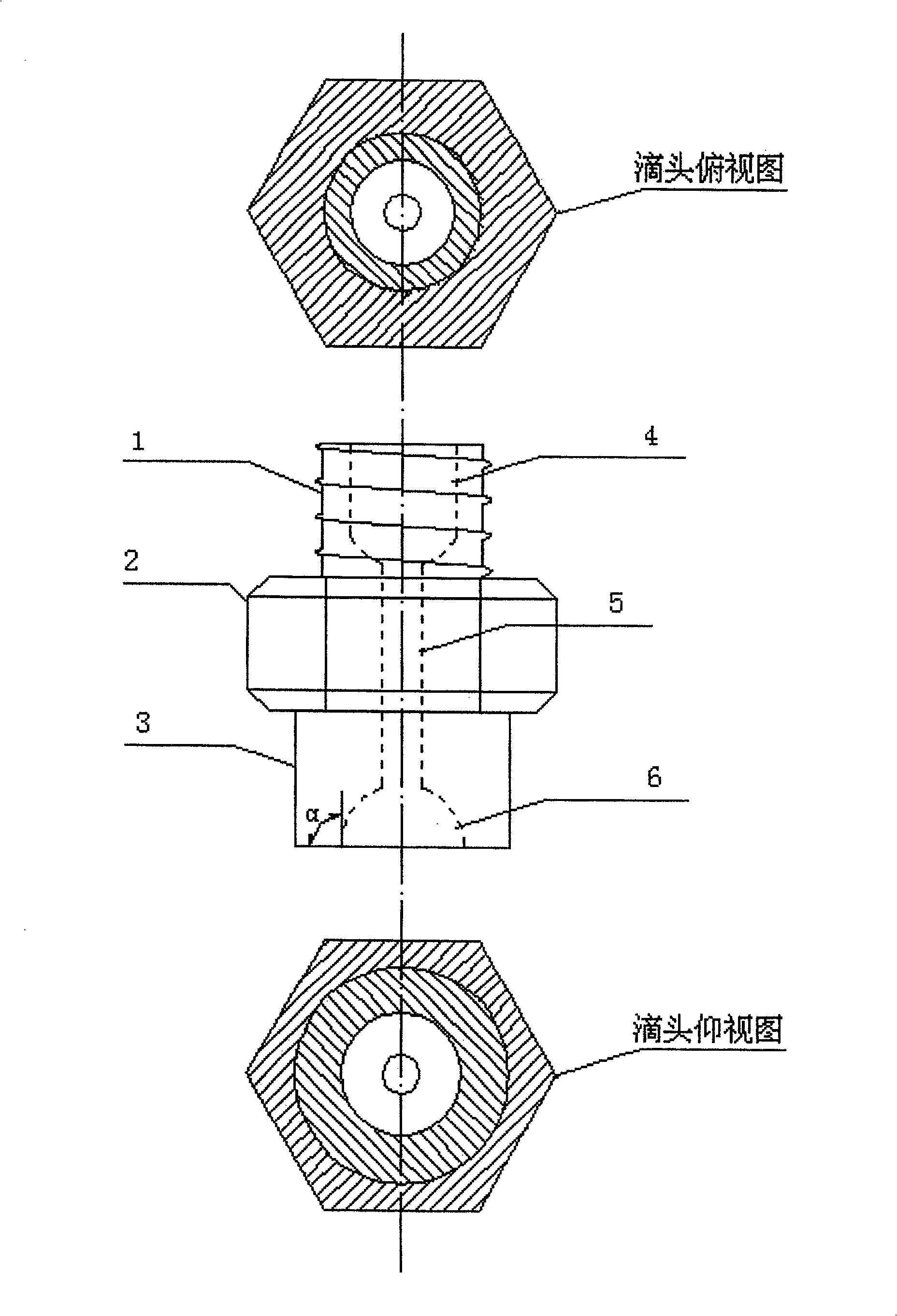

Method used

Image

Examples

Embodiment 1

[0014] Take 1 part by weight of Schisandra Alcohol Extract and add it to the mixed and melted matrix of 2-5 parts by weight of polyethylene glycol 6000 and 1-4 parts by weight of polyethylene glycol 4000, stir well to make a uniform medicinal solution. Under the condition of heat preservation at ℃, use the dripping method of the diameter-limited cylindrical concave nozzle dripper, and gradually cool with 35℃~0℃ dimethyl silicone oil, and separate the oil pellets, at a temperature of 30℃ and a relative humidity of 50%. Dry for 60 minutes under certain conditions, sieve the pills to select the pills, inspect, pack, and obtain.

[0015] Compared with the cylindrical plane nozzle dripper, the difference in pellet weight and qualified product rate of pellet roundness produced by the invention are increased by 27%.

Embodiment 2

[0017] Take 1 part by weight of Schisandra chinensis alcohol extract and add it to 2-6 parts by weight of molten polyethylene glycol 6000 matrix, stir well to make a uniform liquid, and use a diameter-limited cylindrical concave tube under the condition of 90 ° C heat preservation Oral dripping method, cooling with 35°C-5°C dimethyl silicone oil, separating the oil pellets, drying for 30 minutes at a temperature of 30°C and a relative humidity of 50%, and screening the pellets. Inspection, packaging, that is.

[0018] Compared with the cylindrical plane nozzle dripper, the difference in pellet weight and qualified product rate of pellet roundness produced by the invention are increased by 36%.

Embodiment 3

[0020] Take 1 part by weight of Schisandra Alcohol Extract and add it to the mixed and molten matrix of 1-3 parts by weight of polyethylene glycol 6000, 2-6 parts by weight of polyethylene glycol 4000 and 0.1-3 parts by weight of sodium lauryl sulfate, Stir well to make a uniform drug solution, drip it with a cylindrical concave nozzle dropper with a limited diameter at 75°C, cool it with 35°C-5°C dimethyl silicone oil, and separate the oil pellets , dried for 60 minutes under the conditions of a temperature of 30° C. and a relative humidity of 55%, sieving and selecting pellets, inspecting, and subpackaging to obtain the product.

[0021] Compared with the cylindrical plane nozzle dripper, the difference in pellet weight and qualified product rate of pellet roundness produced by the invention are increased by 33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com