Continuous drilling flowrate process capable of predicting coal draft outburst and its apparatus

A coal roadway outburst and flow method technology, applied in mining equipment, safety equipment, earthwork drilling and other directions, can solve problems such as failure to reflect the distribution of pressure relief zones, worker panic, and failure to directly measure gas flow distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

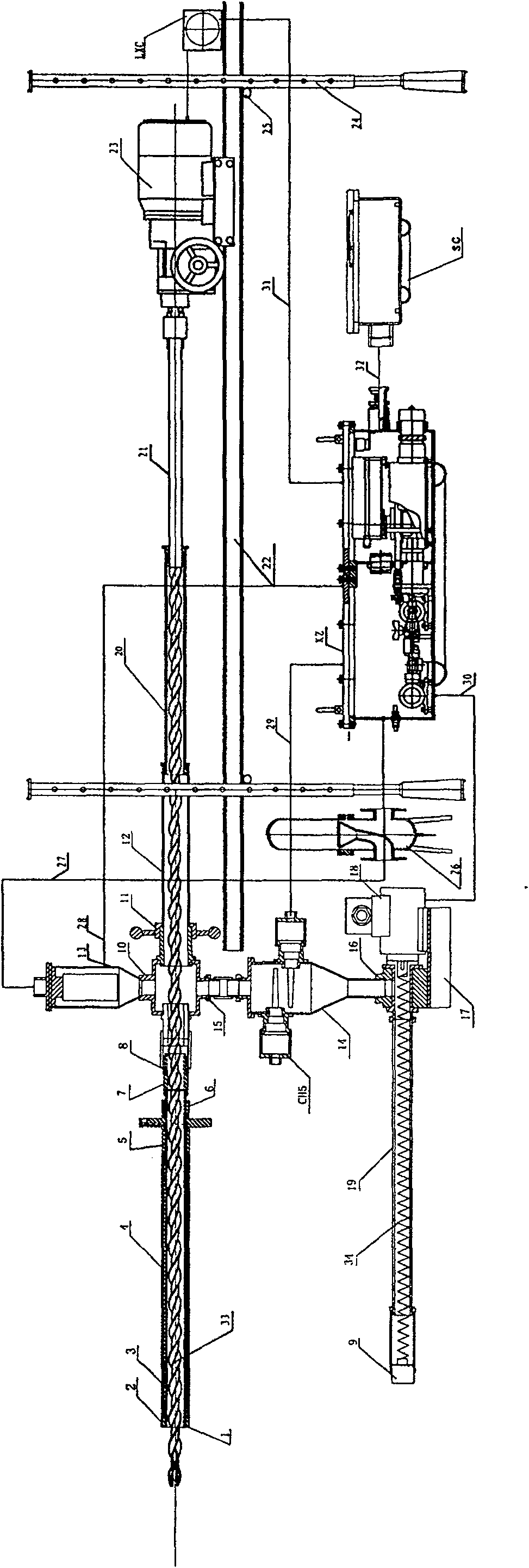

[0023] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

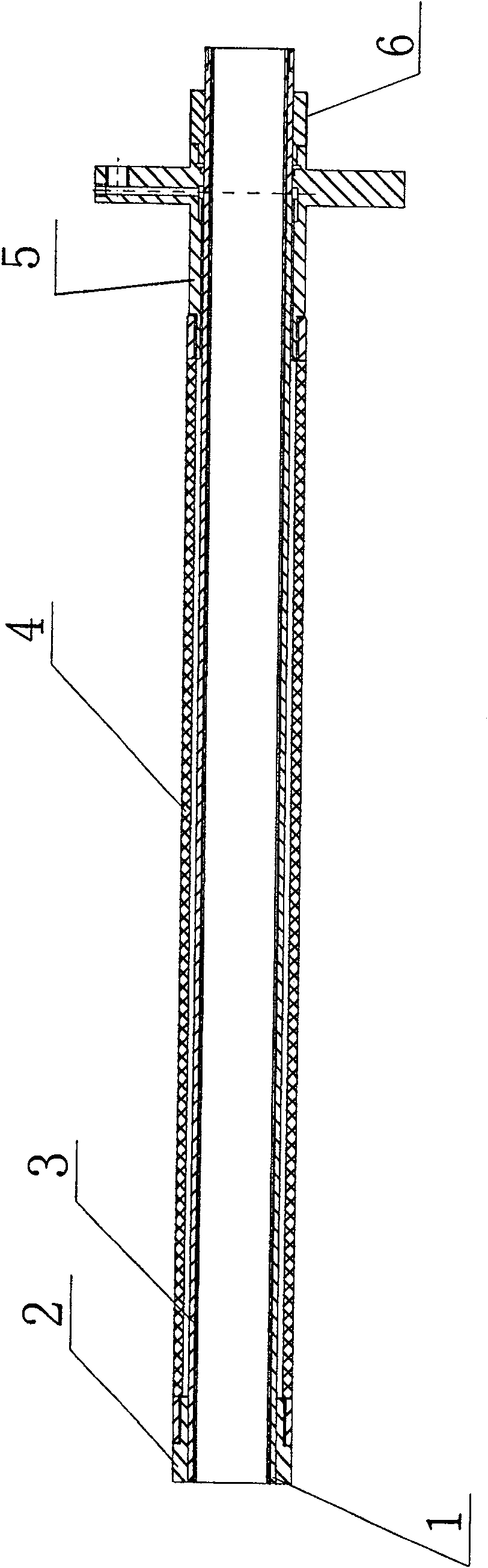

[0024]The present invention predicts the continuous drilling flow rate method of coal roadway protrusion. Firstly, it is required to drill a Φ85mm hole with a length of about 900mm in the direction of the soft coal seam in front of the coal roadway through the coal roadway, and put the hole sealing device in it to make it expand and seal it. Drilling; then connect the front end of the solid-gas separation device 10 with the sealing device, the coal chip controller 14 is connected with the lower part of the solid-gas separator 10, insert the twist drill rod 33 into the hole sealing device and then pass through the telescopic tube 20 is connected with the push rod 21 on the rock electric drill, and the telescopic device is connected to the rear end of the solid-gas separator 10 through the connector 11; the steel wire rope on the displacement sensor LXZ placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com