Spacing mechanical arm parallel modularized joint

A space manipulator and modular joint technology, applied in manipulators, manufacturing tools, joints, etc., can solve the problems of small output torque per unit mass, large joint volume, high power consumption, etc., and achieve high overall rigidity, reliable transmission, power low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

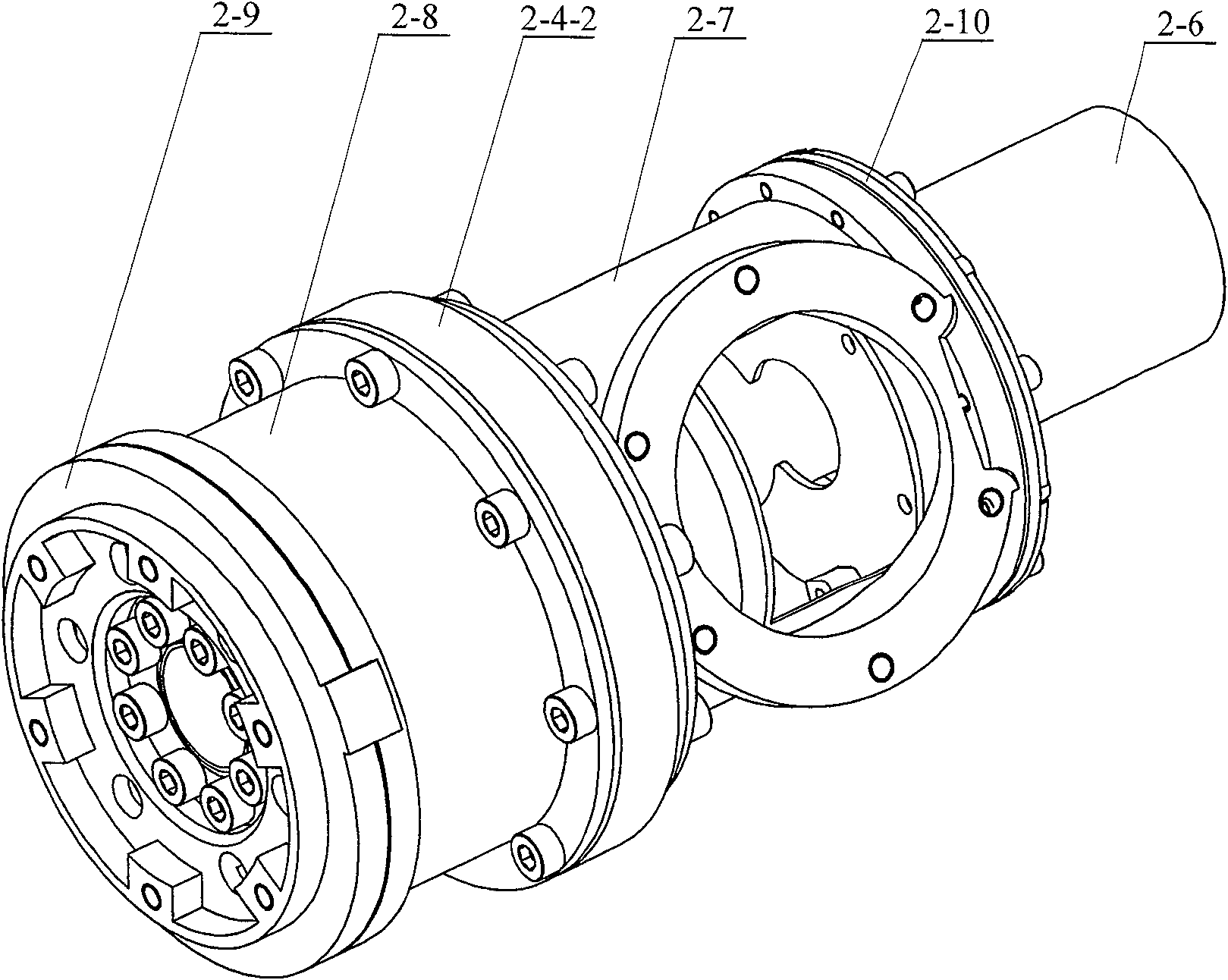

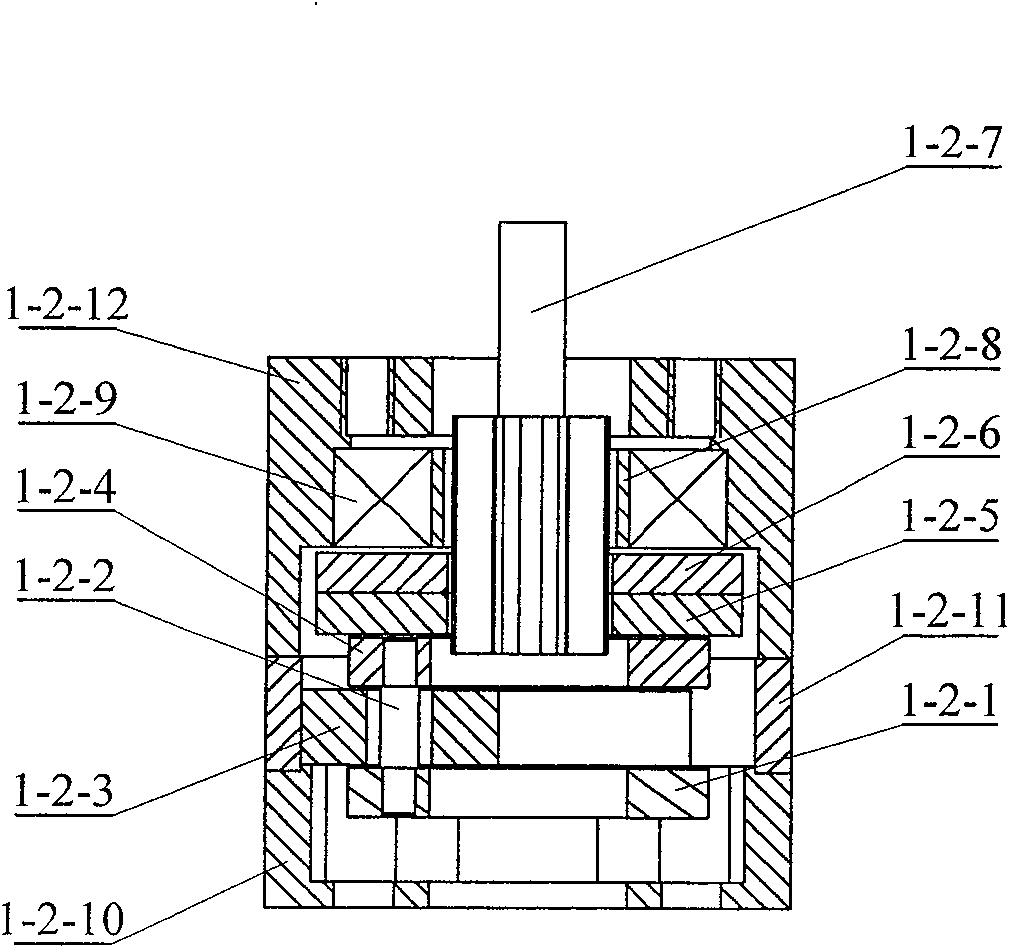

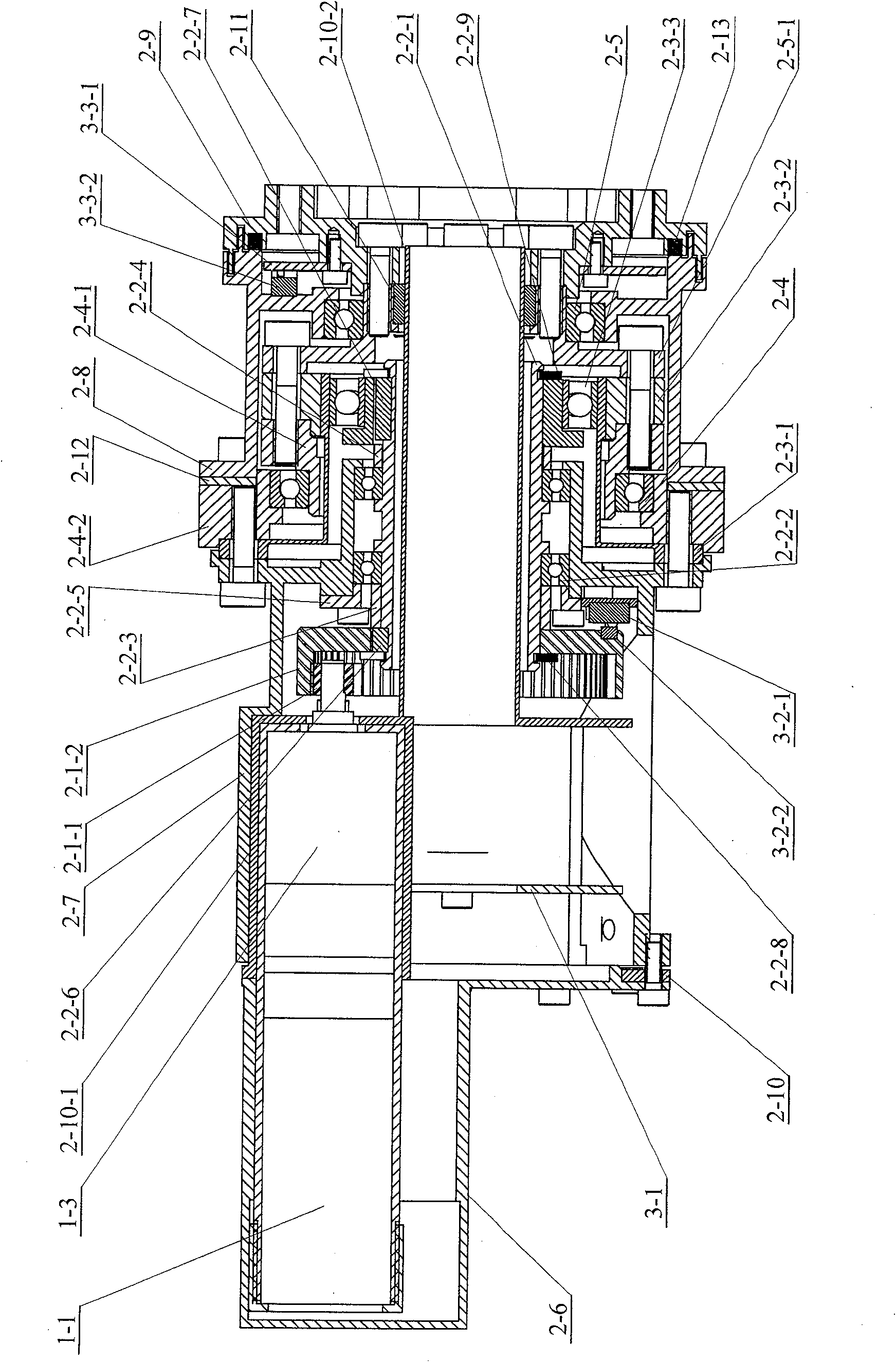

[0006] Specific implementation mode one: (see Figure 1 to Figure 13) This embodiment is composed of a drive device, a joint mechanism and an electrical part. The drive device is composed of a DC brushless motor 1-1, a friction reverse brake, a planetary reducer 1-3, a motor sleeve 1-4 and a motor The sleeve cover 1-5 is composed of, and the joint mechanism is composed of an internal meshing gear device, a hollow drive shaft device, a harmonic reducer, a thin-walled bearing 2-4, a thin-walled bearing 2-5, and an inner thin-walled bearing Ring support seat 2-4-1, thin-wall bearing first outer ring support seat 2-4-2, thin-wall bearing second inner ring support seat 2-5-1, joint rear end cover 2-6, first shell 2- 7. The second shell 2-8, the output flange 2-9, the sleeve 2-10, the isolation support ring 2-11, the adjusting gasket 2-12 and the felt 2-13, the electrical part is composed of connected to circuit board 3-1, hall switch and position sensor 3-3, and the internal meshi...

specific Embodiment approach 2

[0007] Specific embodiment 2: The coefficient of friction between the inner walls of friction plate 1-2-5, friction plate 2 1-2-6 and shell 3 1-2-12 described in this embodiment is greater than Where r is the radius of the pitch circle of the output gear shaft 1-2-7, R is the inner diameter of the housing 3 1-2-12, and b is the width of the opening groove on the friction plate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0008] Embodiment 3: In this embodiment, the radius of the inner hole of the thin-walled bearing-inner ring support seat 2-4-1 is 0.8 mm larger than the maximum radius of the toothed end of the flexspline 2-3-1. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com