Method for reactive sputter deposition of an ultra-thin metal oxide film

A sputter deposition, oxide film technology, applied in sputter coating, metal material coating process, manufacturing/processing of electromagnetic devices, etc., can solve problems such as MTJ performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]

[0025] The method of the present invention can be applied to the formation of the tunnel barrier required by the MTJ read head. However, this method is fully applicable to the formation of tunnel barriers for other MTJ devices and the formation of ultra-thin (less than about 100 ) More general applications of metal oxide films.

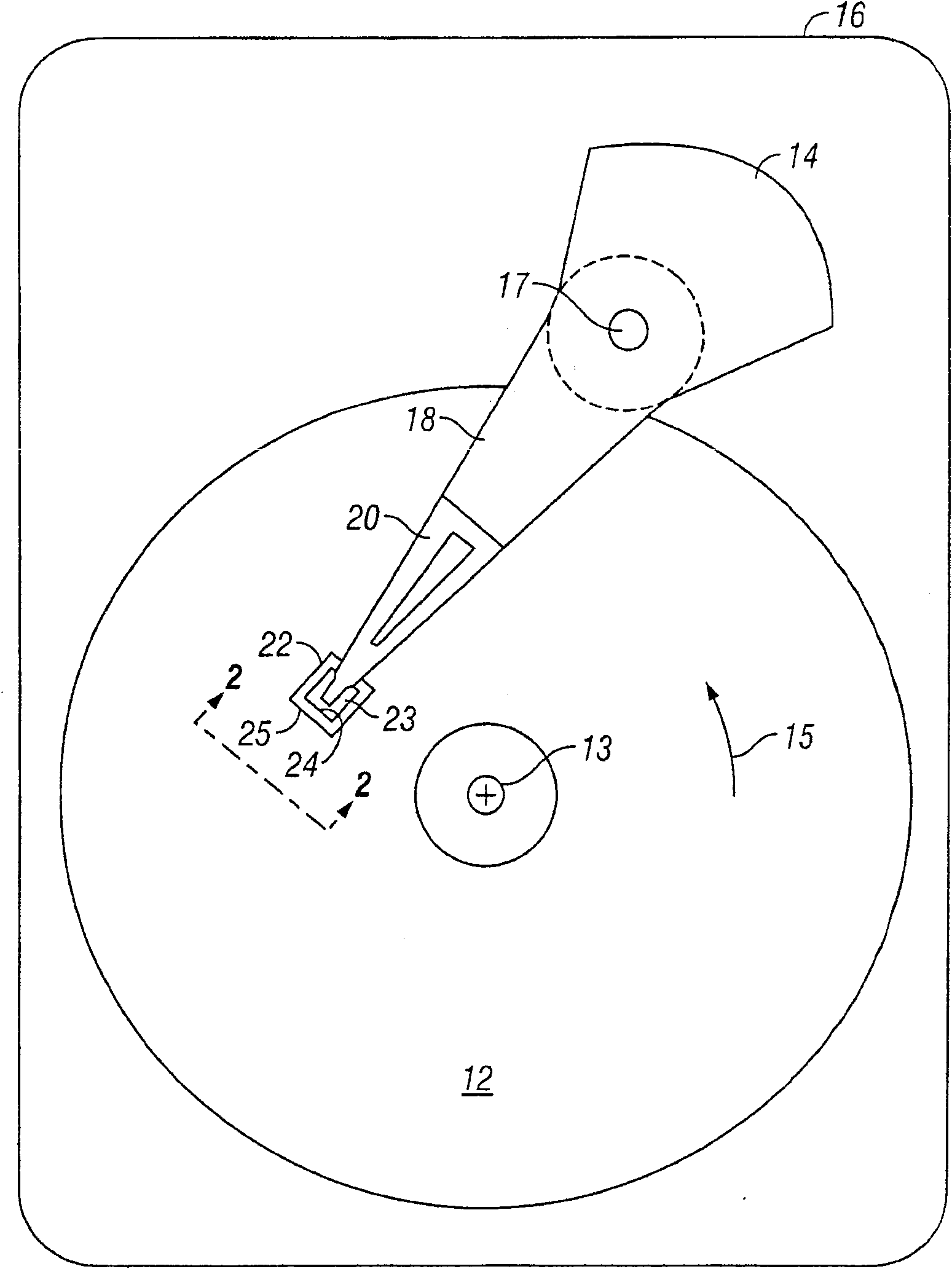

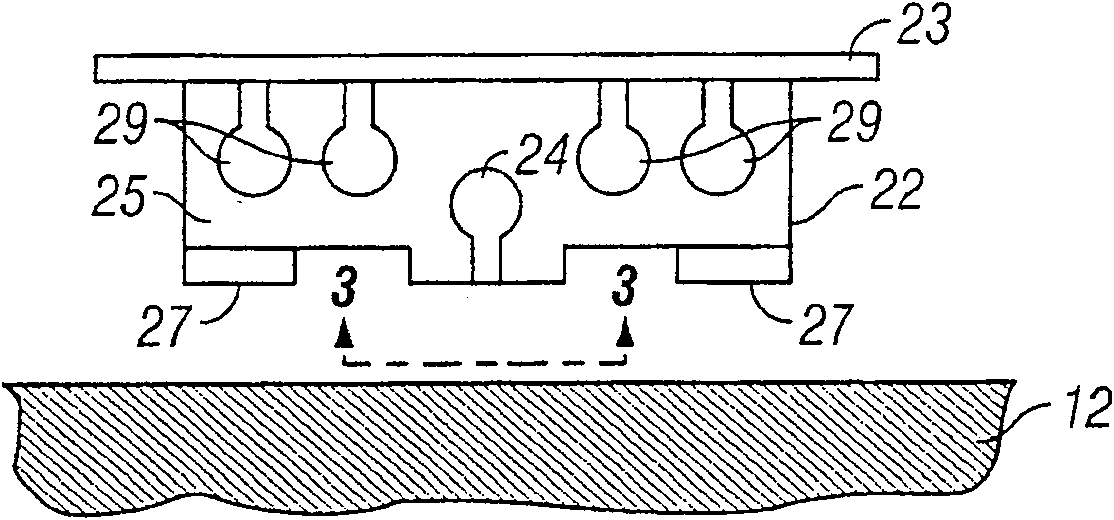

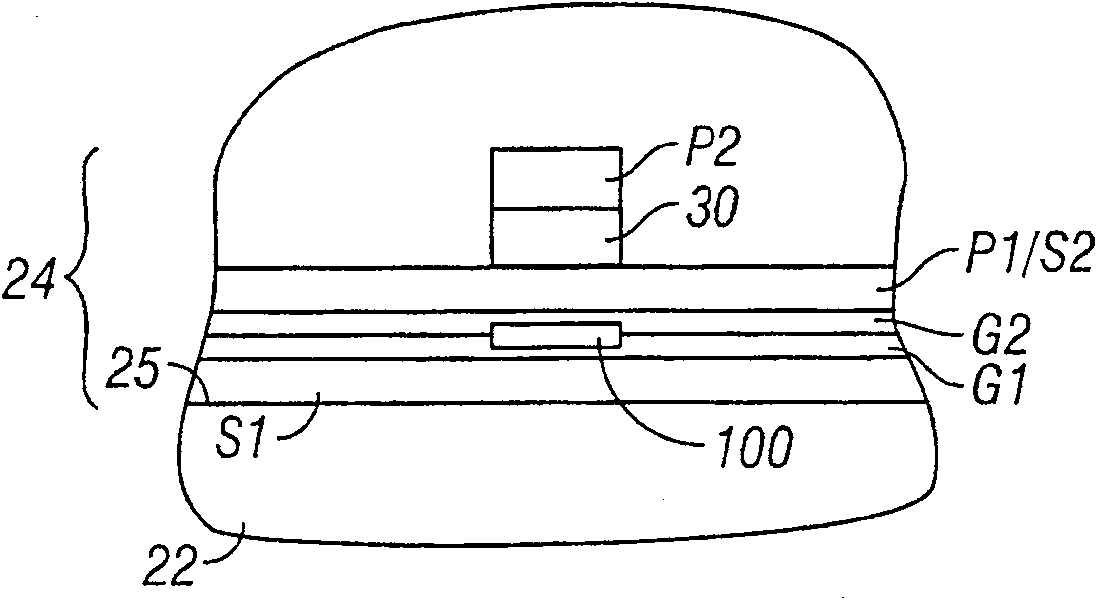

[0026] Since the MTJ read head has applications in magnetic recording disk drives, reference will be made to Figure 1-3 Briefly describe the operation of a conventional hard disk drive (HDD). figure 1 It is a simplified diagram of a conventional magnetic recording hard disk drive 10. The disk drive 10 includes a magnetic recording disk 12 and a rotating voice coil motor (VCM) actuator 14 supported on a disk drive housing or base 16. The disk 12 has a center of rotation 13 and is rotated in a direction 15 by a spindle motor mounted to the base 16. The actuator 14 rotates around a shaft 17 and includes a rigid actuator arm 18. The suspension 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com