Plastic regeneration process and plastic regeneration machine

A process method and recycling machine technology, applied in the field of plastic recycling, can solve the problems of screw and barrel wear, easy twisting of the screw, high maintenance costs, etc., and achieve the effects of improving quality, saving production costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

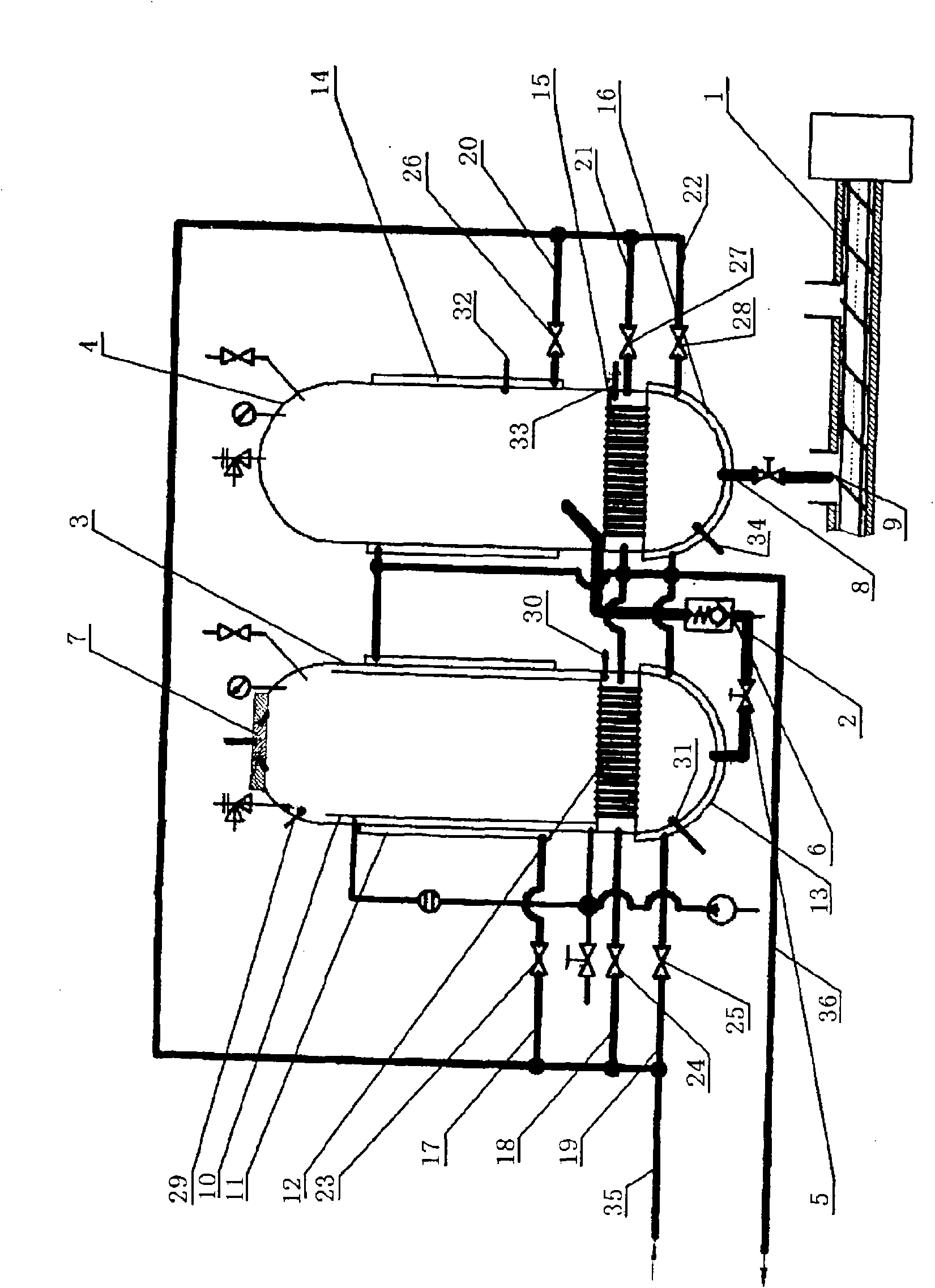

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] The steps of the plastic regeneration process are as follows: A. Put the cleaned plastic into a container and heat it to melt. The containers used for melting the plastics in this step are two containers connected in series in sequence. After the plastics are put into the containers, they are heated in stages along the direction of entering and flowing out, and their temperatures are increased sequentially. The feed port of the plastic container is provided with locks and seals, and its discharge port is provided with a regulating valve. The container is provided with a water-filled interlayer, and heat is transferred to the plastic by means of high-temperature water vapor formed after heating. And squeeze the melted plastic out of the container. B. Inject the melted plastic into the extruder and extrude it.

[0011] exist figure 1 In the embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com