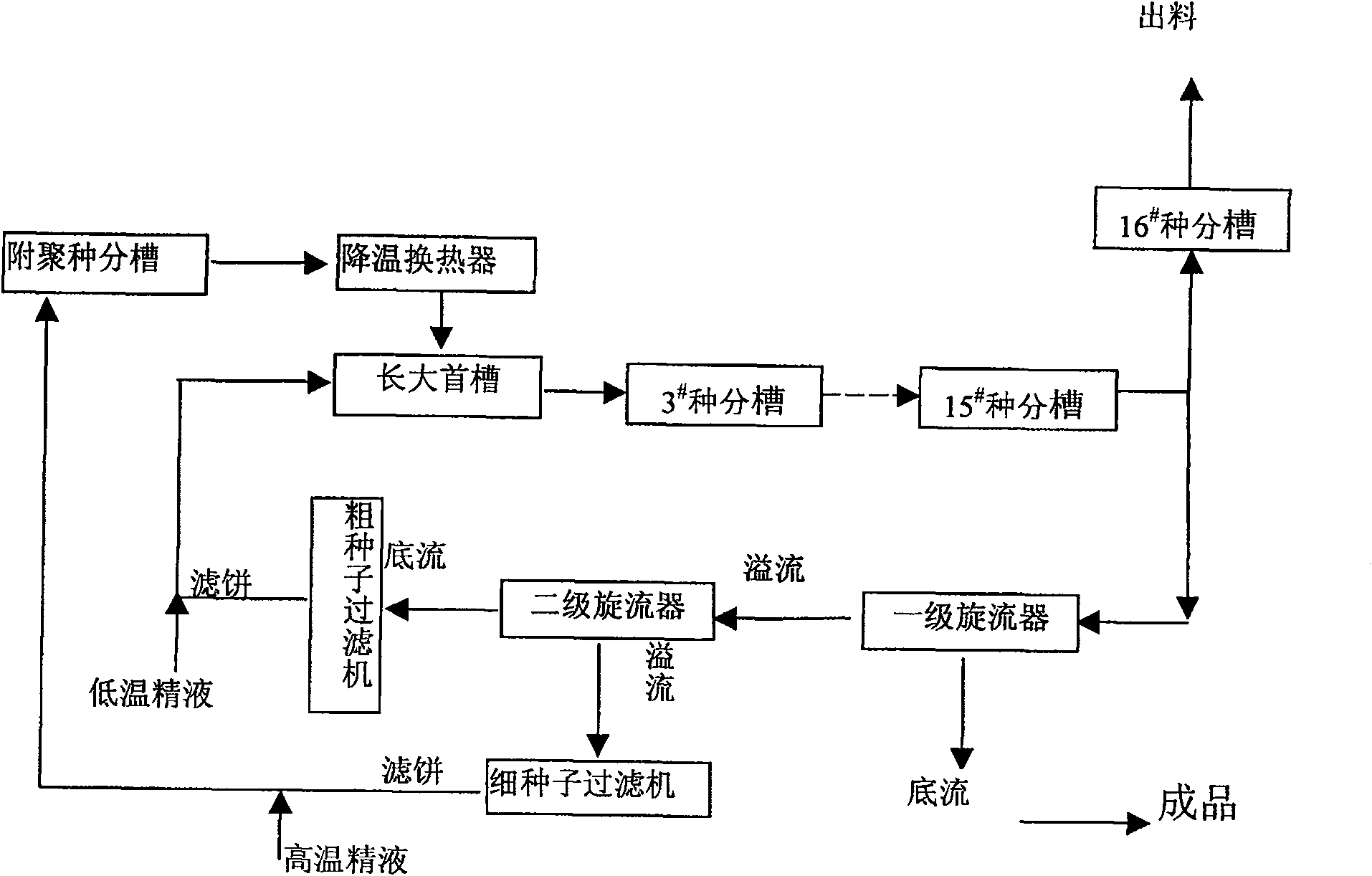

Small two-stage method aluminium hydroxide crystal seed decomposing method

A technology of aluminum hydroxide and two-stage method, which is applied in the direction of aluminum oxide/aluminum hydroxide, to achieve the effects of reasonable process, good economic and social benefits, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Use 20% of the 81°C decomposed stock solution for high-temperature agglomeration, and the other 80% of the decomposed stock solution is cooled to 61°C and decomposed by a one-stage method. The average content of the product aluminum hydroxide-45μ is 14.5%, the decomposition rate is 52.12%, and the output rate is 84.84 kg-A0 / m 3 -semen.

Embodiment 2

[0013] Use 25% of the 81°C decomposed stock solution for high-temperature agglomeration, and the other 75% of the decomposed stock solution is cooled to 61°C and decomposed by a one-stage method. The average content of the product aluminum hydroxide-45μ is 12.5%, the decomposition rate is 52.75%, and the output rate is 85.02 kg-A0 / M 3 -semen.

Embodiment 3

[0015] Use 45% of the 78°C decomposed stock solution for high-temperature agglomeration, and the other 55% of the decomposed stock solution is cooled to 63°C and decomposed by a one-stage method. The average content of the product aluminum hydroxide-45μ is 13.5%, the decomposition rate is 52.35%, and the output rate is 85.01 kg-A0 / m 3 -semen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com