Taking-out back water reciprocating flue type boiler

A flue-type, extraction-type technology, applied in water heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of difficult to move and transport, large coal consumption, and low heat utilization rate. The production cost is low, the safety is good, and the effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

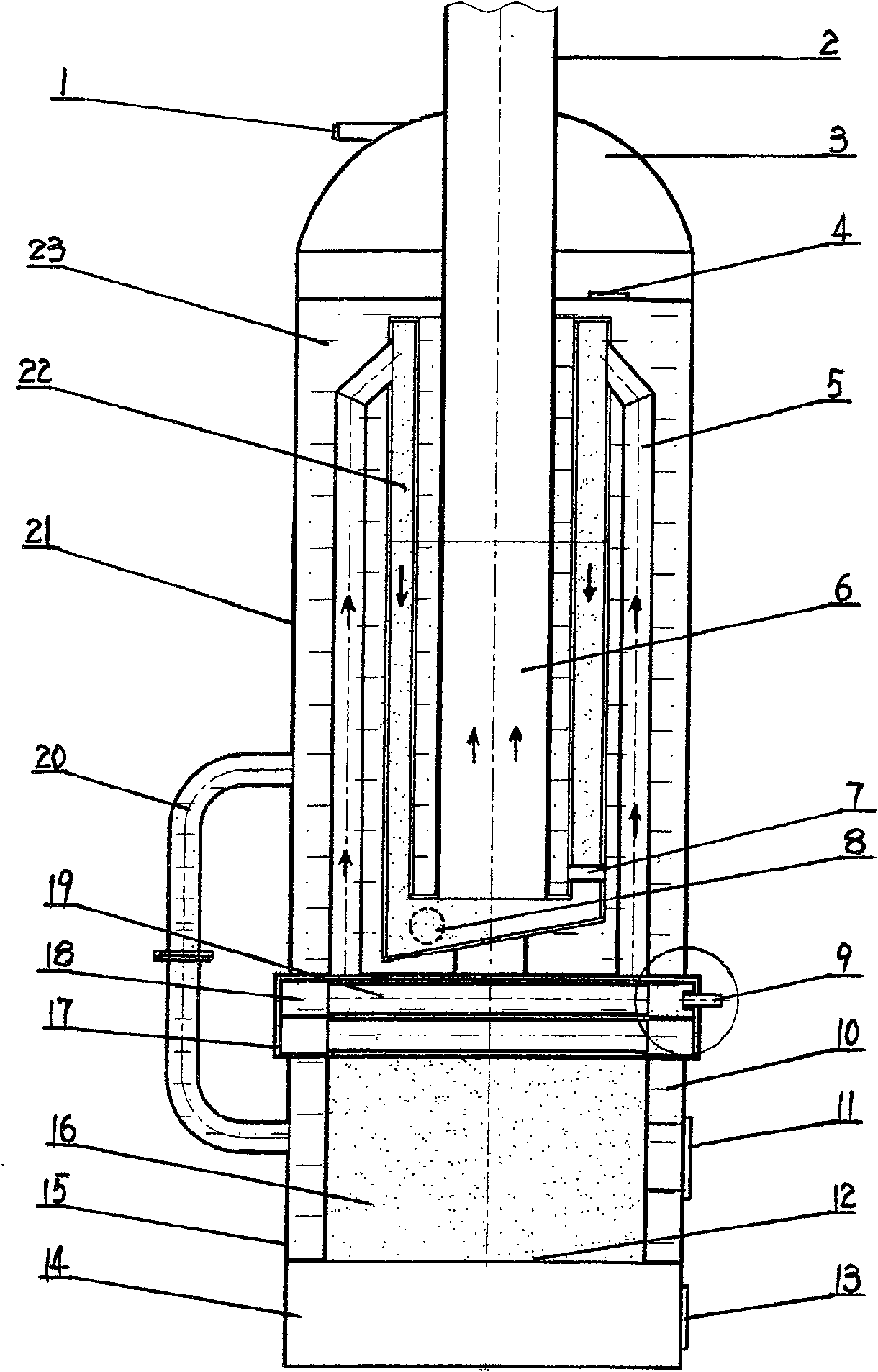

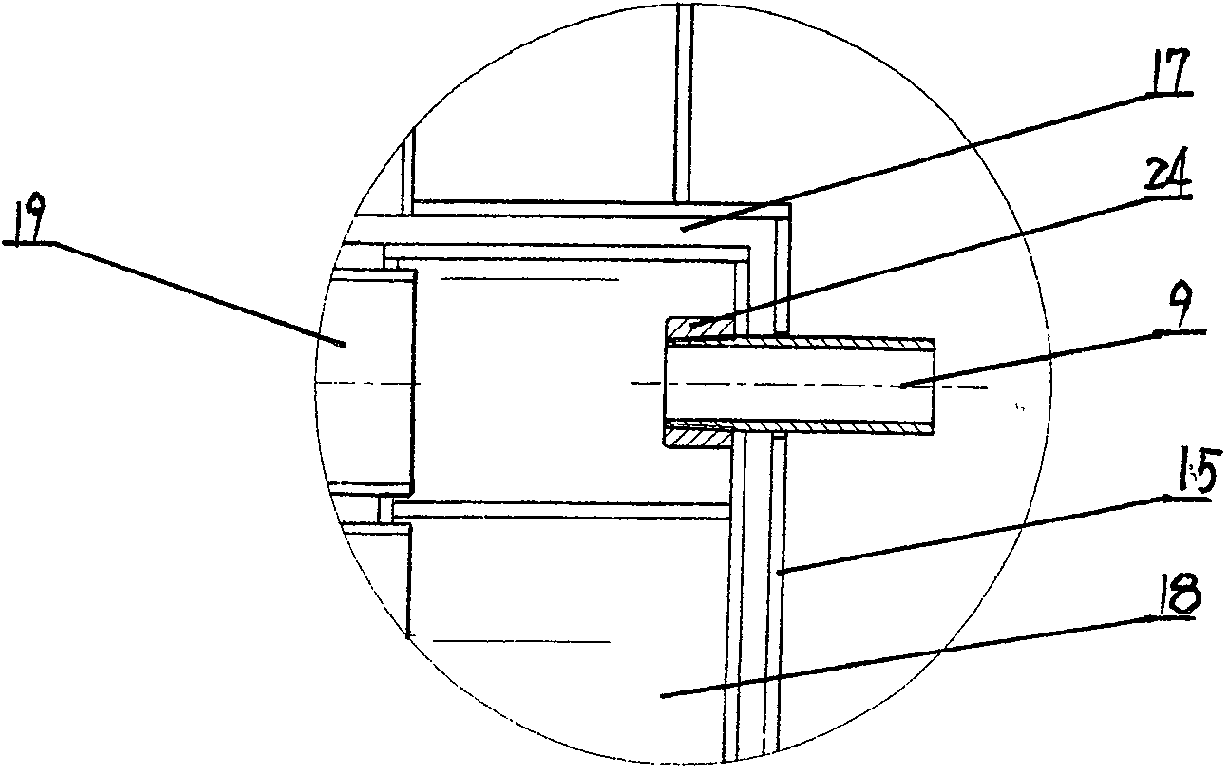

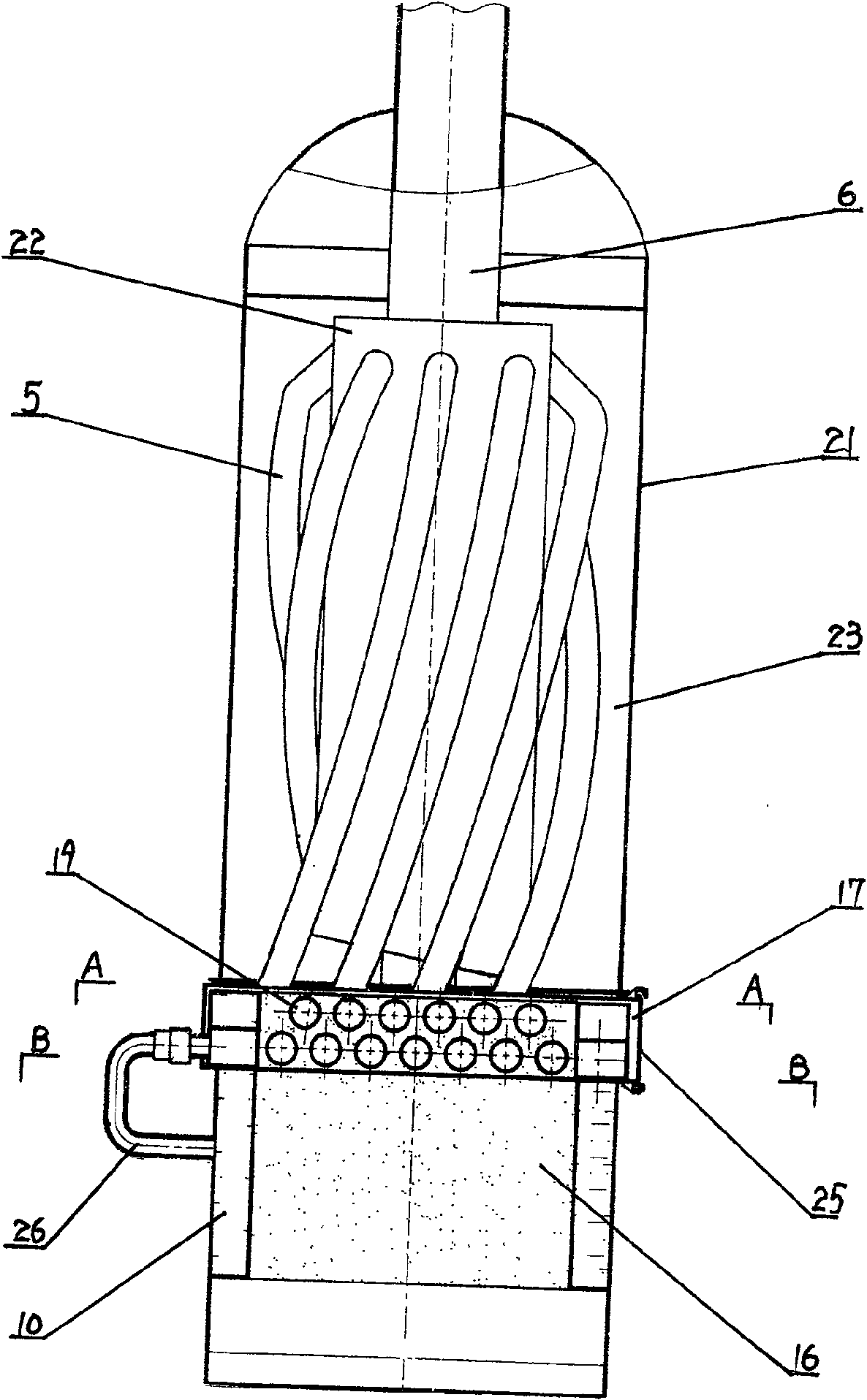

[0013] Such as figure 1 and figure 2 As shown, a reciprocating flue boiler with extraction and backwater mainly consists of an upper furnace body 21, a water storage tank 3, a water inlet pipe 1, a water outlet pipe 9, a furnace grate 12 and a smoke outlet 2.

[0014] Such as figure 1 As shown, the boiler is divided into two parts, the upper and lower furnace bodies. The upper and lower furnace bodies are installed independently, and the detachable water tanks are also independently installed, which are manufactured independently and assembled and combined into one when used. The upper part of the upper furnace body is a water storage tank, and the water inlet pipe communicates with the water storage tank at the upper end of the upper furnace body. The upper furnace body at the lower end of the water storage tank is the upper furnace body water bladder 23 . Lower furnace body 15 is positioned at upper furnace body lower end, and lower furnace body top is provided with for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com