Intelligent abrasive granule jetting treatment apparatus for treating dental caries

An abrasive particle and jet cavity technology, which is applied in the fields of filling teeth, medical science, dentistry, etc., can solve the problems of no processing state identification and error compensation system, no large-scale product processing, precision processing, etc., to achieve no pain and good effect. , The effect of high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

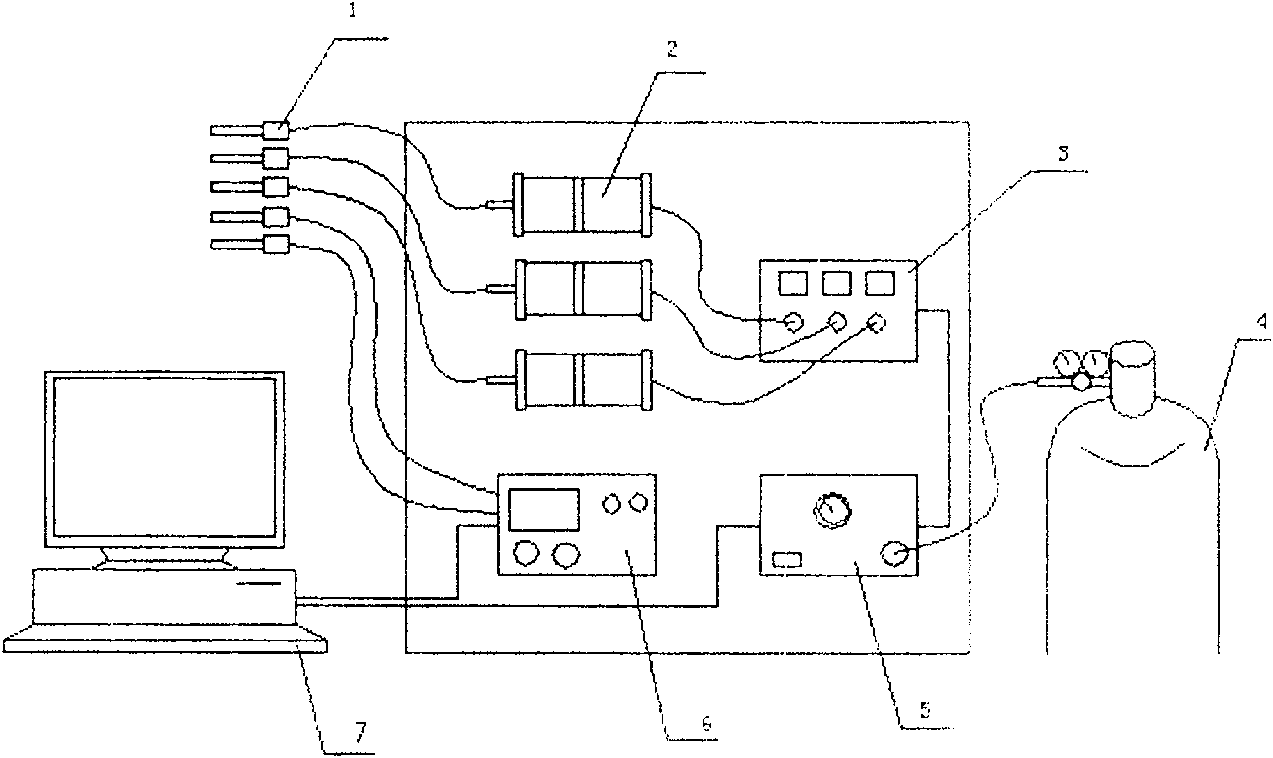

[0024] see figure 1 , The basic structure of the embodiment of the present invention is mainly composed of injection head 1, injection chamber and pressurization valve 2, throttle controller 3, gas cylinder 4, pressure regulator 5, signal processing unit 6 and computer 7 and other parts. The laser light source and CCD image recognition camera in the injection head 1 are connected to the signal processing unit 6 controlled by the computer 7 to realize image collection, recognition and analysis, and the standard sample library for caries treatment is stored in the computer 7 . The jet nozzles for removing plaque and abrasive grains, the medicine cleaning treatment nozzles and the dental filling nozzles in the jet head 1 are respectively connected to the three jet chambers that can be filled with raw materials and the pressurizing valve 2 through jet del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com