Plastic uptake forming system and volumetric packaging machine

A blister molding and three-dimensional packaging technology, applied in the field of machinery and equipment, can solve problems such as poor sealing, difficult collection, and leaking, so as to avoid poor sealing or leaking, compensate for uneven arrangement, and ensure process quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

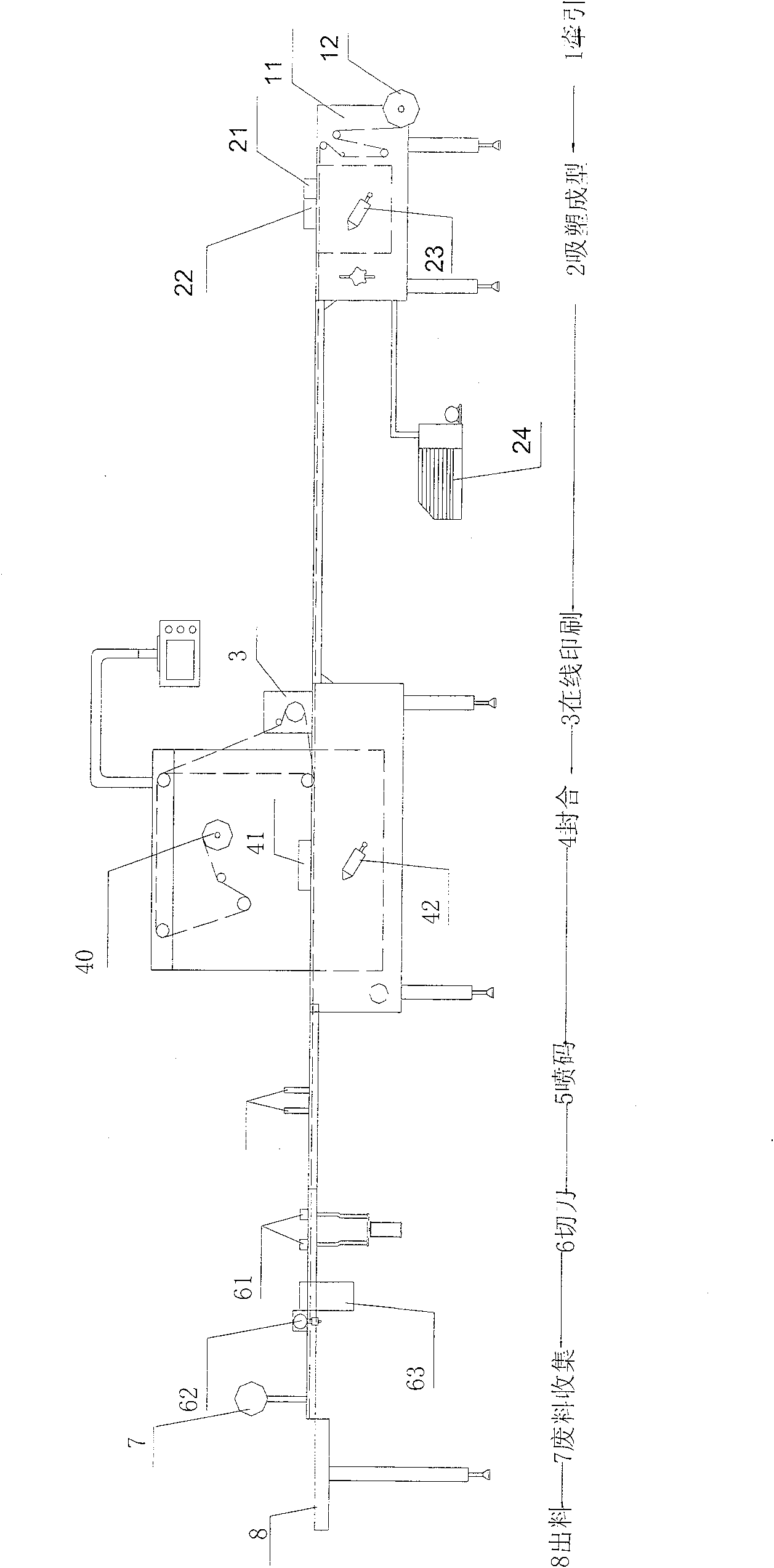

[0039] like figure 1 As shown, the three-dimensional packaging machine of the present invention includes a traction system 1, a blister forming system 2, an online printing system 3, a sealing system 4, a coding system 5, a cutter system 6, a scrap winding collection system 7, a discharge System 8, PLC control system and frame 11.

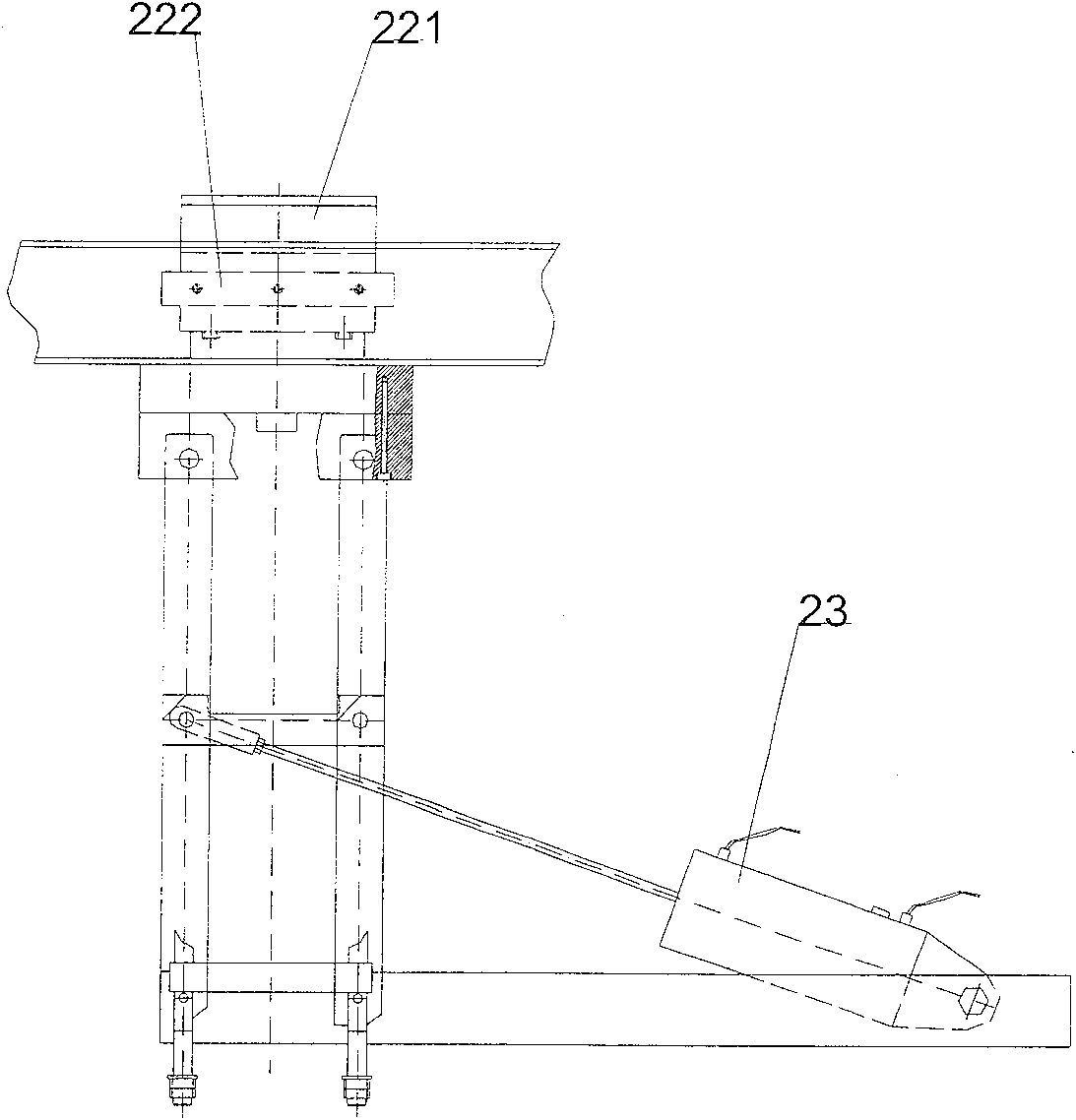

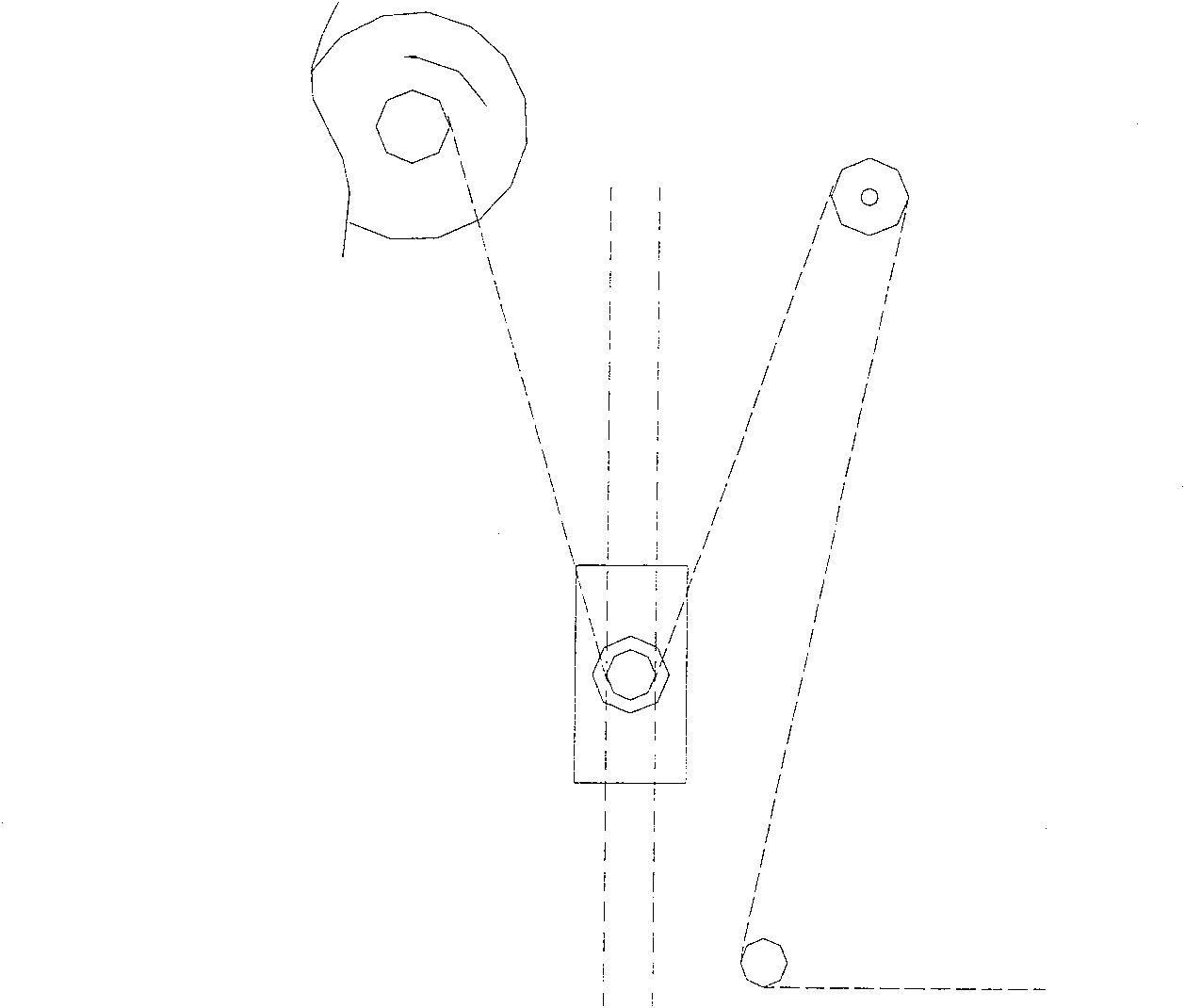

[0040] The traction system is divided into two parts: the film traction system and the expandable winding system. The film traction system is a servo drive system, which mainly uses a servo motor as the driving actuator to drive the chain and the mushroom clip through gear meshing and sprocket transmission. sports. During the traction process, the two edges of the lower film material film 12 used for forming are clamped in the mushroom clip and move forward periodically; the expandable winding system is mainly composed of a paper shaft and an expansion mechanism, and the expansion mechanism consists of An elastic steel sheet supports the core of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com