Pawl-type dry vacuum pump rotor

A dry vacuum pump and rotor technology, applied in the direction of rotary piston pumps, pumps, rotary piston machinery, etc., can solve the problems of difficult dynamic balance processing, unreasonable structural design, long processing time, etc., to reduce raw material consumption, Effect of light weight and shortened processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

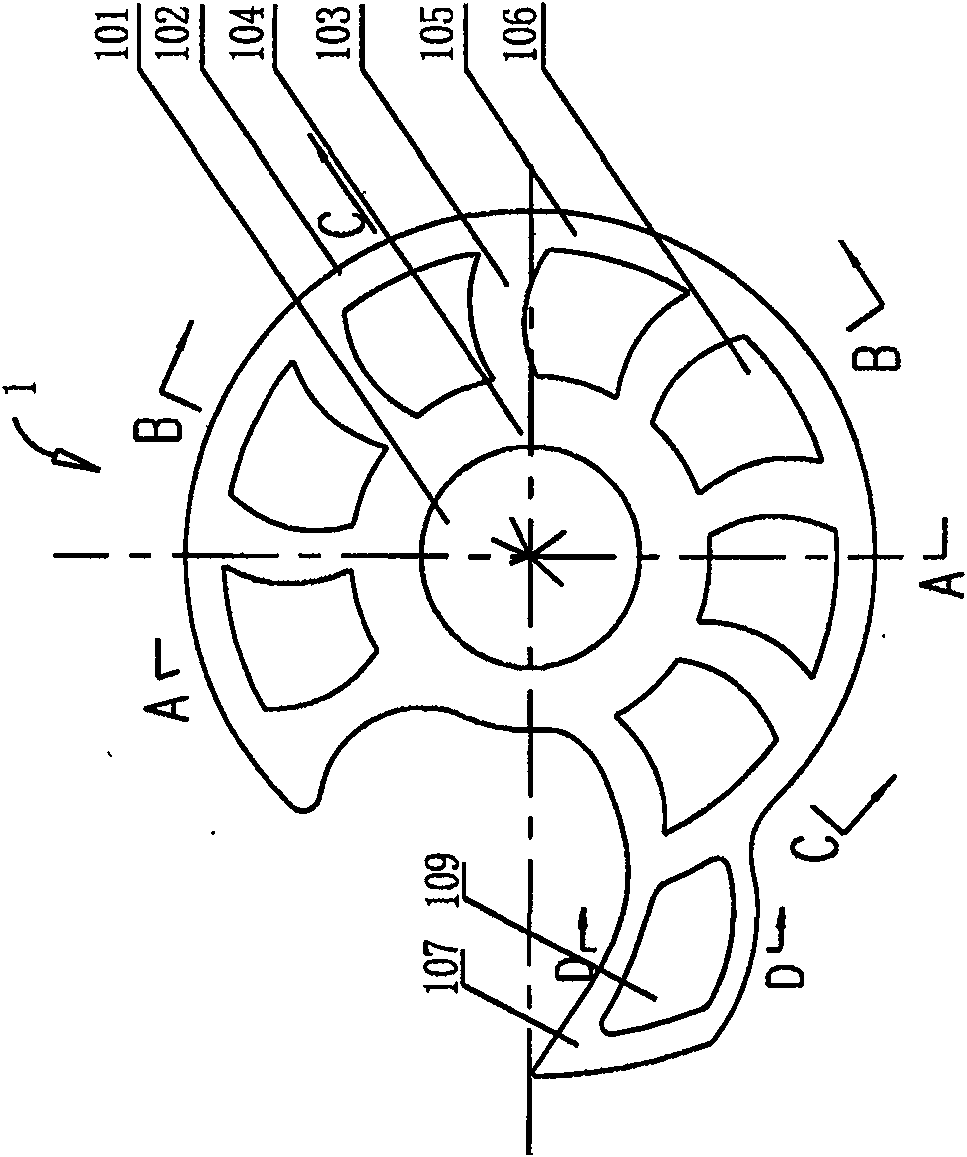

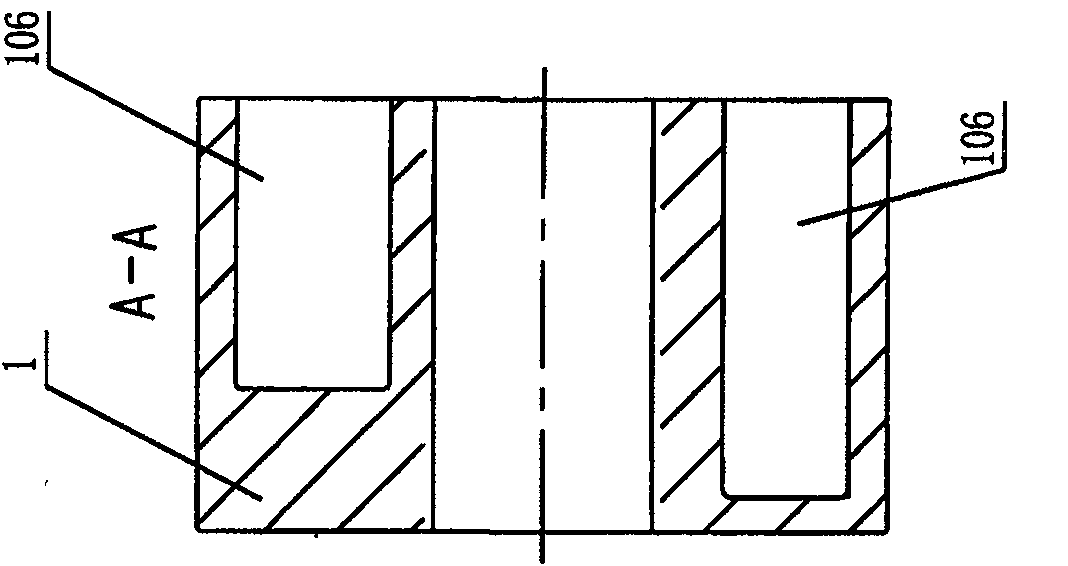

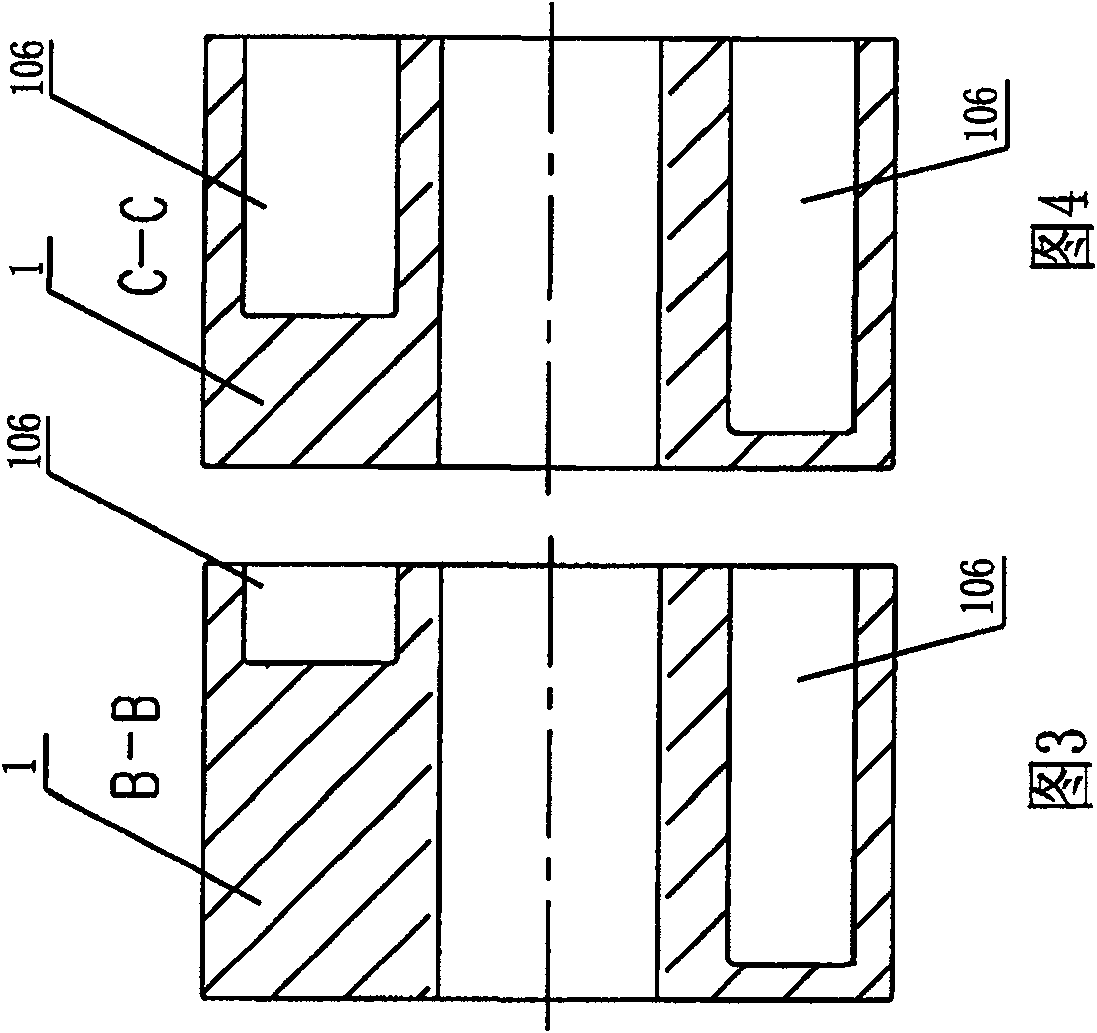

[0017] refer to figure 1 As shown, a claw-type dry vacuum pump rotor has several reinforcing ribs 103 evenly distributed on the circumference between the shaft hole 101 of the rotor body 1 and the wall thickness of the outer wall 102, so that the rotor body 1 is in the shape of a hollow wheel. , forming the hub 104 and the hub 105, the radial width of the hub 104 is greater than the radial width of the hub 105; the several road reinforcing ribs 103 can be arc-shaped, straight or oblique, and each reinforcing rib 103 The circumferential width from the inner end to the hub 104 is smaller than the circumferential width from the outer end to the spokes 105, and the hollowed out portion of the rotor body 1 is approximately trapezoidal in shape of a slot 106, and may also be circular, elliptical, quadrilateral or other. Polygonal shape, etc.; the radial dimensions of the slots 106 are the same, but the axial dimensions are different in depth.

[0018] refer to figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com