TIG welding method

A welding method, a technology for joining surfaces, applied in the field of arc welding, which can solve the problems of high skill, complexity of the joining area, and non-constant welding thickness and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

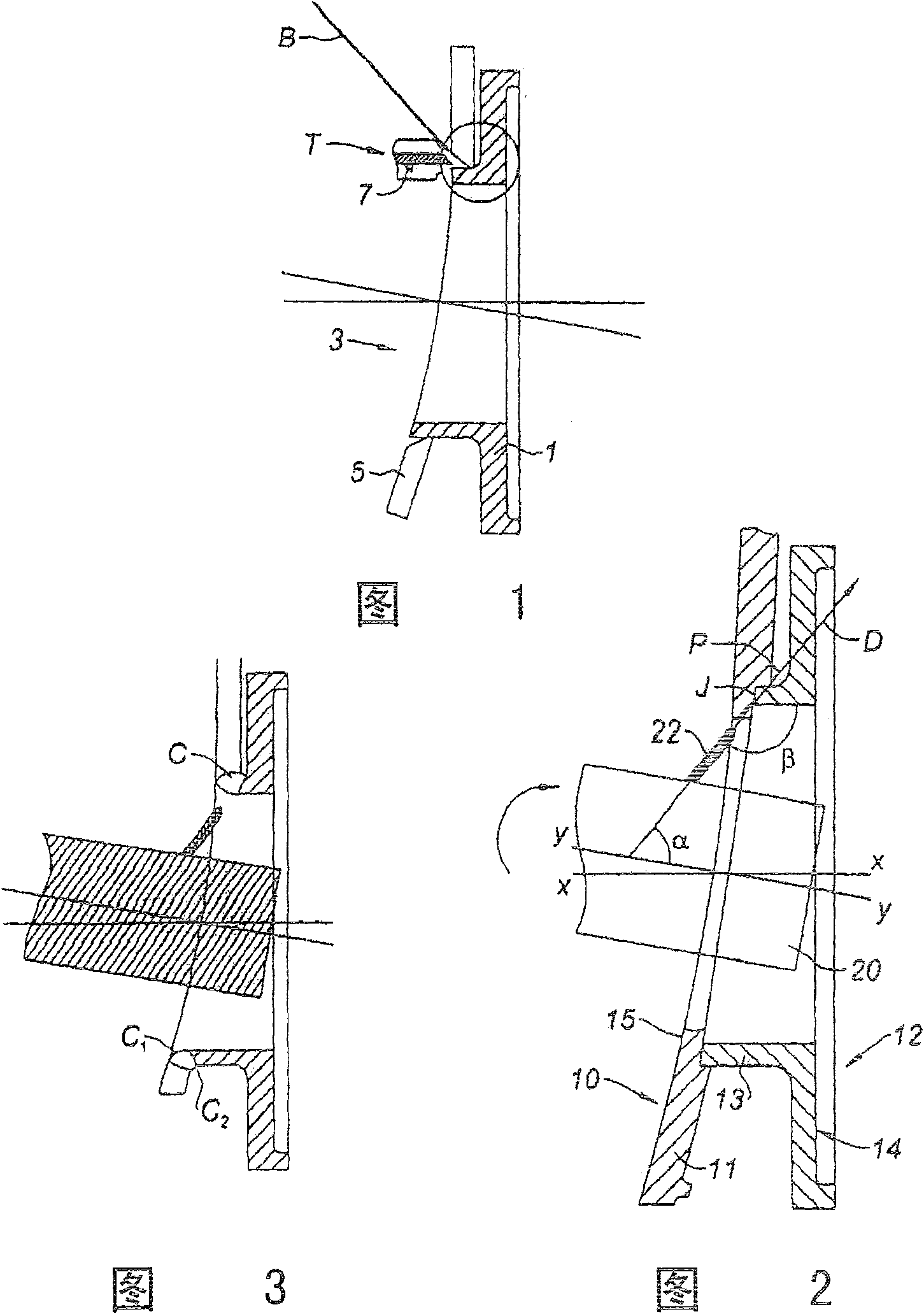

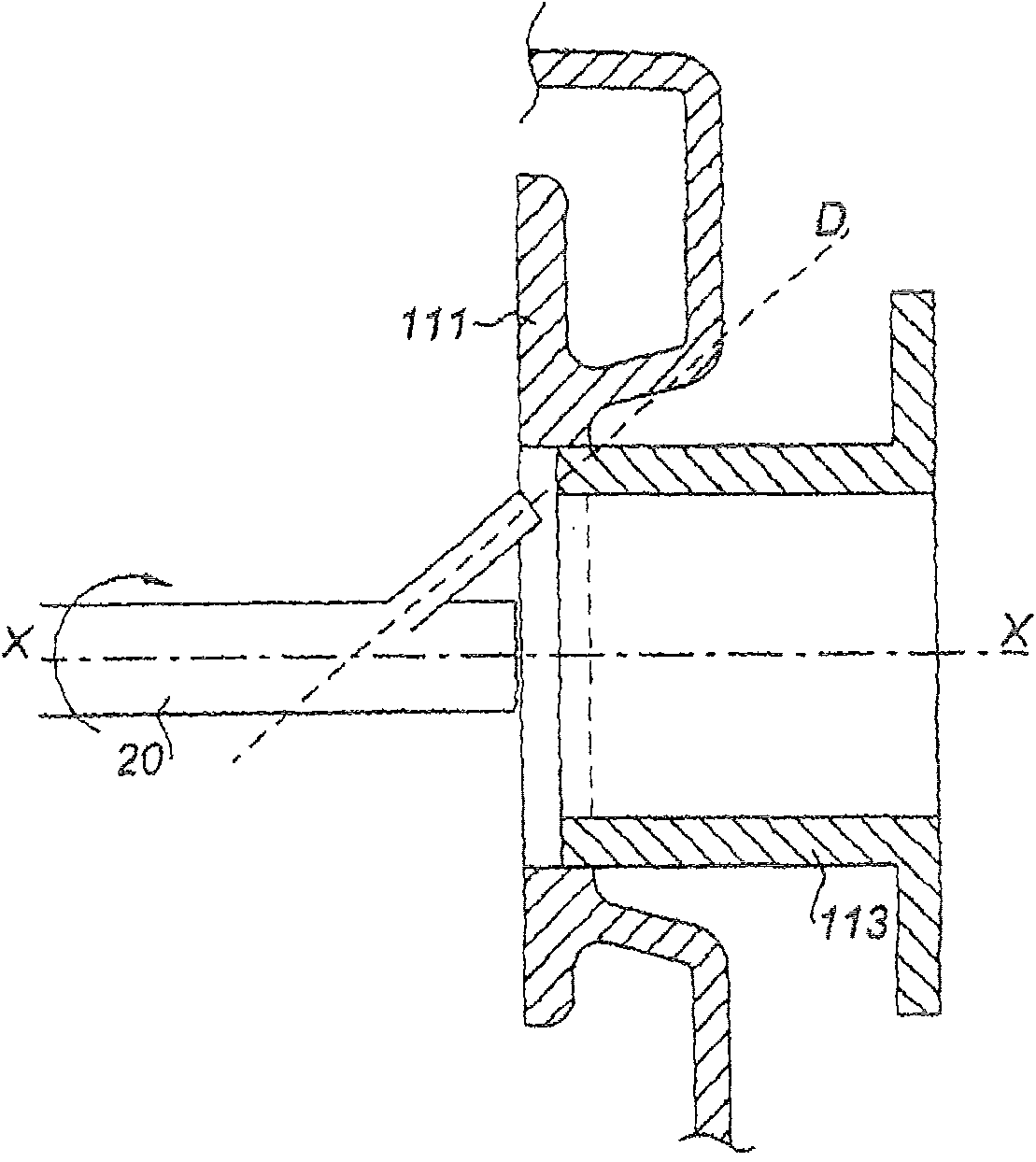

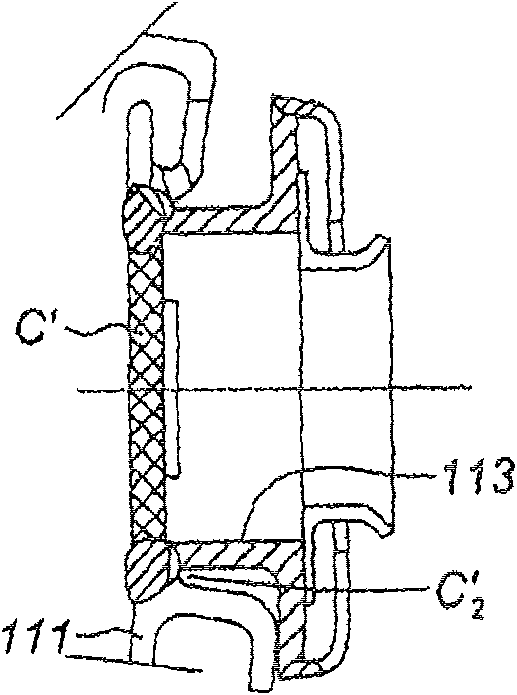

[0022] figure 2 Denotes a part of the casing 11 of the turbojet combustion chamber 10, which is at the level of the spark plug hole channel. The spark plug is shown without the remaining housing. Spark plug guide 12 may hold the spark plug in place within the combustion chamber. This first part consists of a cylindrical part 13 with axis XX and a mounting flange 14 extending along the outer edge of the cylindrical part.

[0023] The casing 11 of the combustion chamber is substantially cylindrical, usually with a dome-shaped portion directing the updraft. Axial openings are provided therein, not shown in the figures, through which means for supplying fuel and combustion air to the combustion chamber pass. The spark plug ignites the air and fuel mixture.

[0024] In order to fix the conduit 12 to the housing 11 a circular through hole is drilled. The wall thickness around the hole is thinned by reaming in the vertical axis YY, forming the support surface against which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com