Method for measuring heat productivity of heating substance for calorimeter

A measurement method and calorific value technology, which is applied in the field of measuring instruments, can solve problems such as the complexity of the cooling model, and achieve the effects of ensuring accuracy, ensuring accuracy, ensuring unidirectionality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see Figure 4 As shown, a method for measuring the calorific value of exothermic substances used in a calorimeter of the present invention, a method for measuring the calorific value of exothermic substances used in a calorimeter, is characterized in that the steps are:

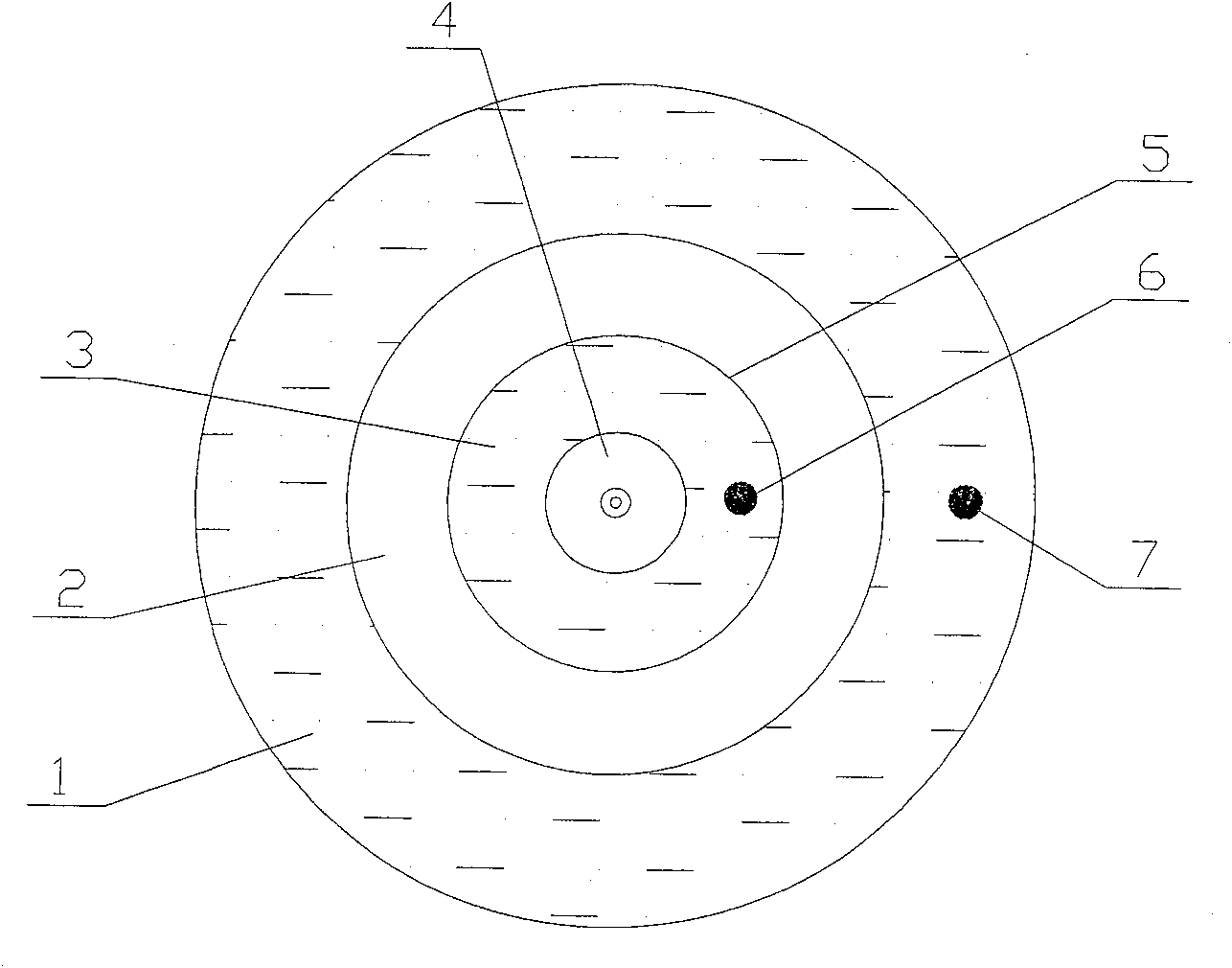

[0024] (1), take the air-dried sample and place it in the crucible, place the loaded crucible on the crucible support of the oxygen bomb, and install the ignition wire; add distilled water into the oxygen bomb, and fill the oxygen bomb with an appropriate amount of oxygen;

[0025] (2) Add an appropriate amount of water (such as 1L) into the inner barrel of the calorimeter, put the oxygen bomb into the inner barrel, and cover the lid;

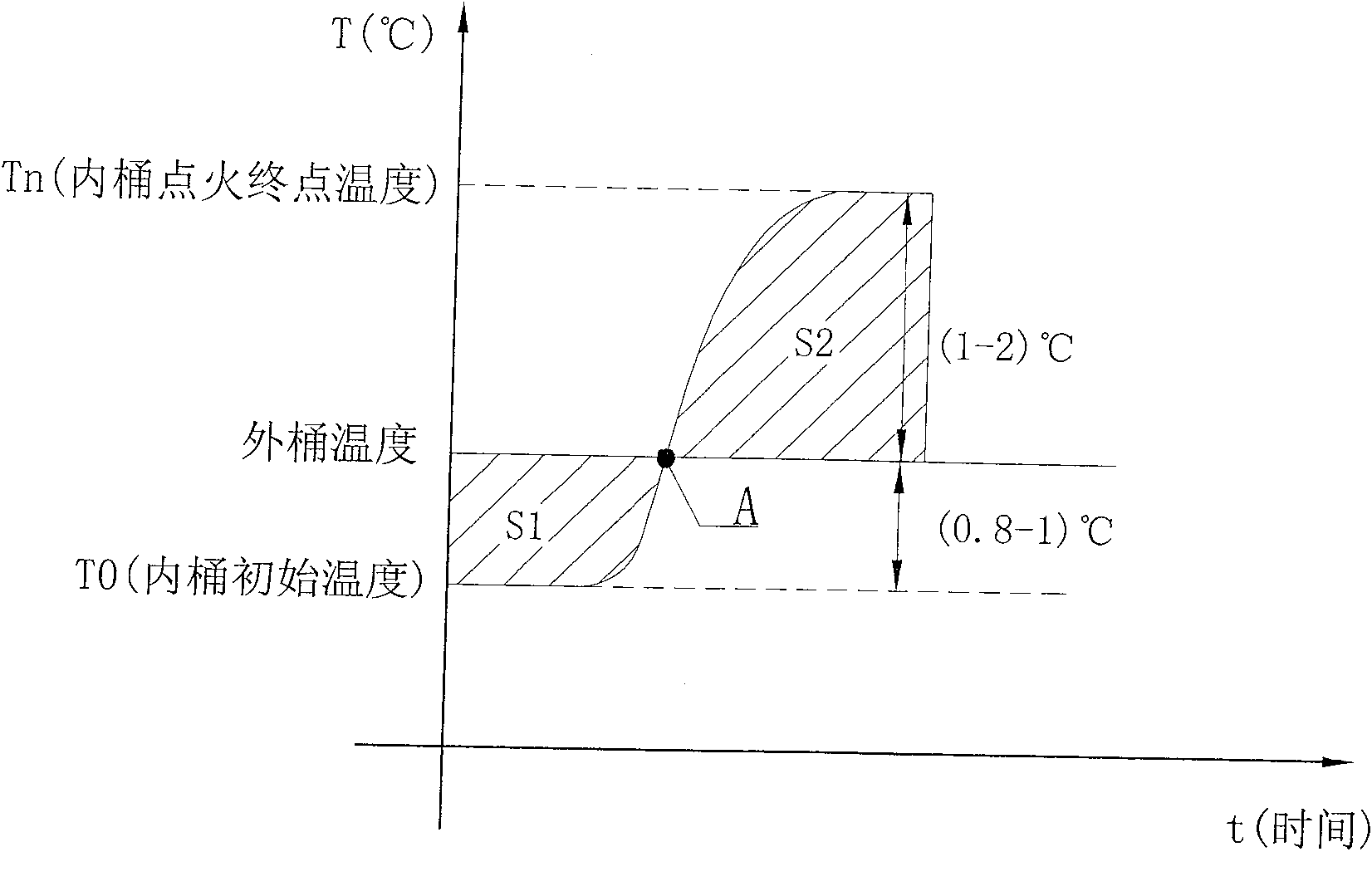

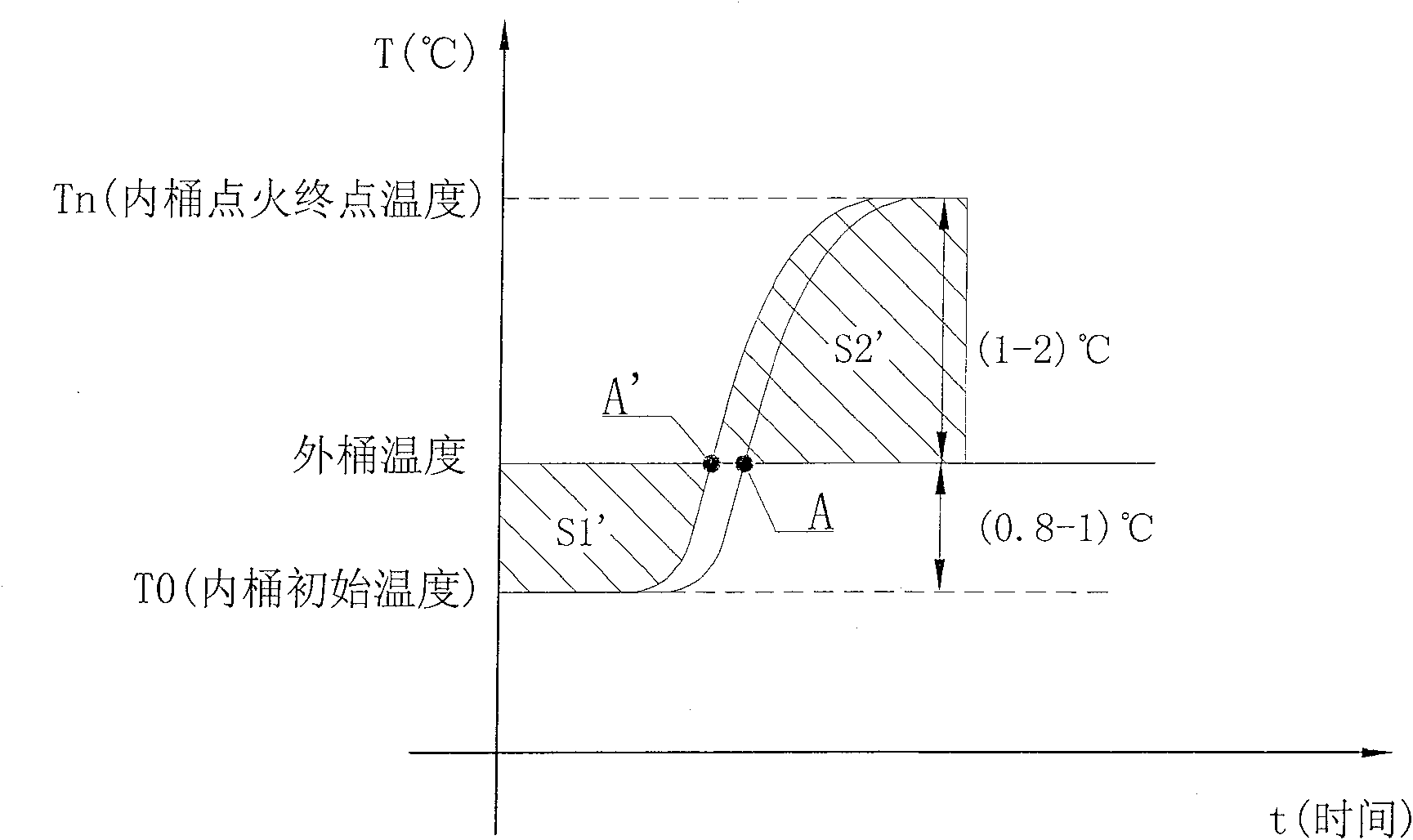

[0026] (3) After starting the inner barrel to stir for about 5 minutes, the temperature of the inner barrel reaches the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com