A new type index tag and manufacturing method

A production method and technology for signs, which can be applied in the directions of signs, instruments, display devices, etc., and can solve the problems of single variety, metal falling off, and instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the utility model is described in further detail.

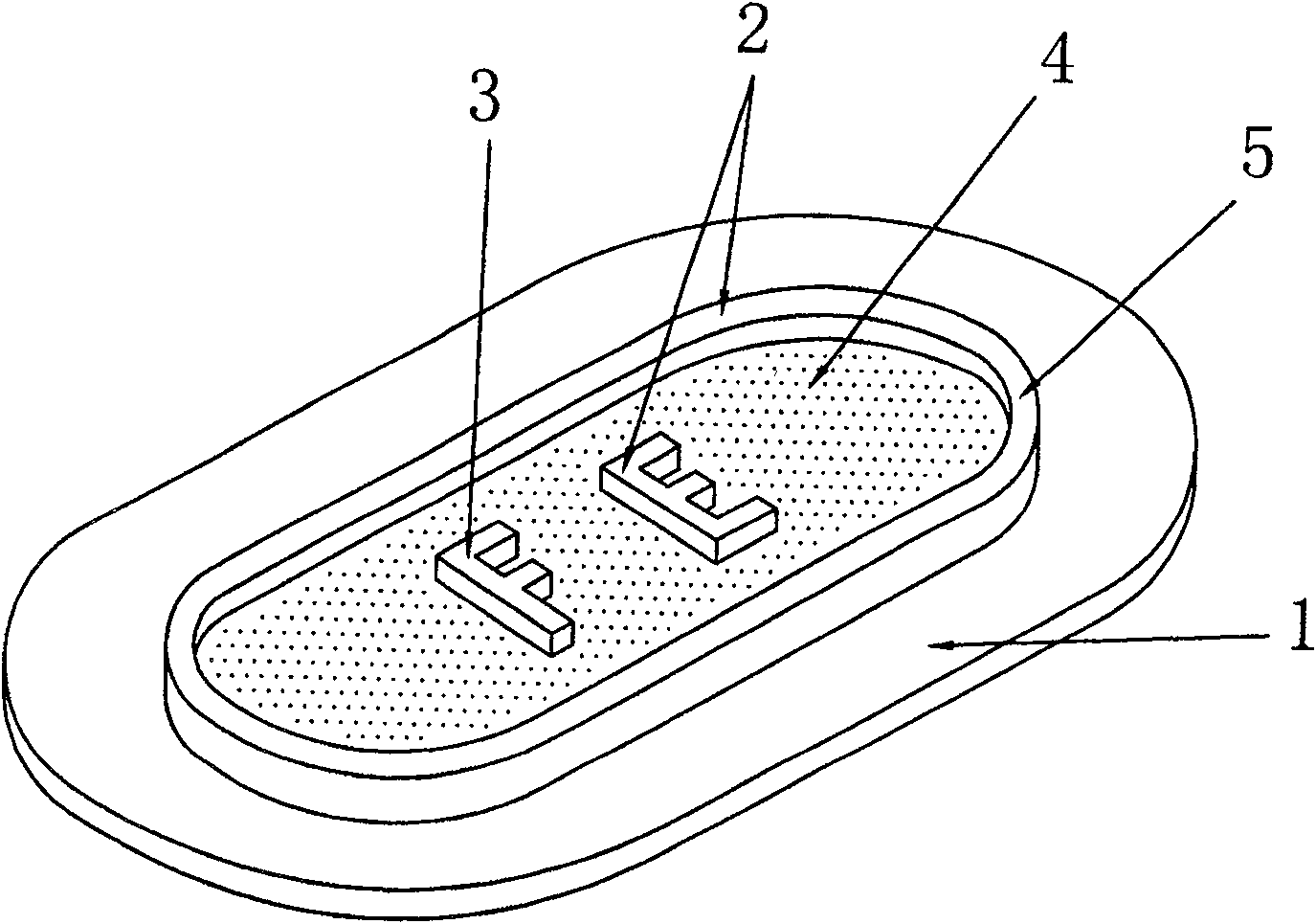

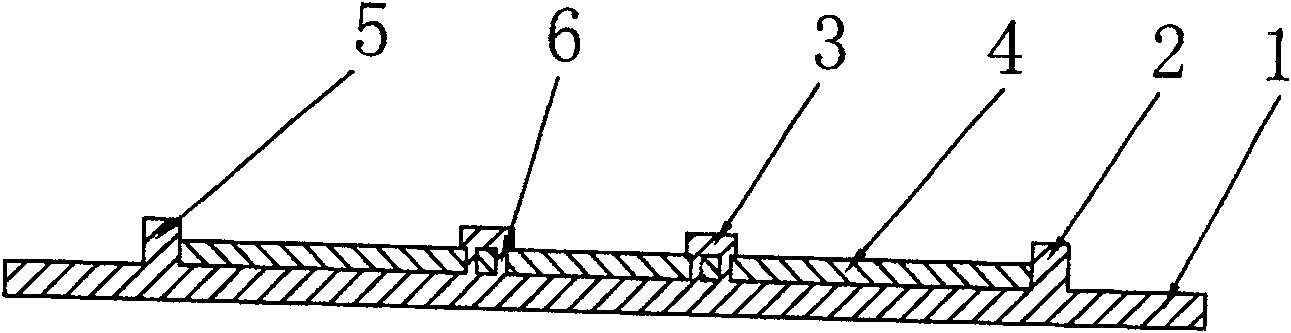

[0019] Such as figure 1 , figure 2 Shown, a kind of novel label and manufacturing method, described novel label comprises a plastic lower mold layer 1 and a plastic upper mold layer 2, and described upper mold layer 2 is formed by an upper mold cavity 21 (not shown in the figure) ) is formed with recessed or raised marks 3, and a metal plate body 4 is fitted between the upper mold layer 2 and the lower mold layer 1, and a metal plate body 4 is provided on the metal plate body 4 corresponding to the depression of the upper mold cavity 21. There are fine and small holes 6 for liquid to pass through.

[0020] The upper and lower mold layers form upward protrusions 5 on the peripheral edge of the metal card body to press the card body. The upper and lower mold layers 1, 2 are respectively formed by the upper and lower mold cavities 11, 21, the upper mold cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com