Control method of cold calender einlaufbereich

A control method and entrance section technology, applied in metal rolling, tail end control, metal rolling, etc., can solve problems such as strip scratches, improve quality, reduce strip head scratch rate, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

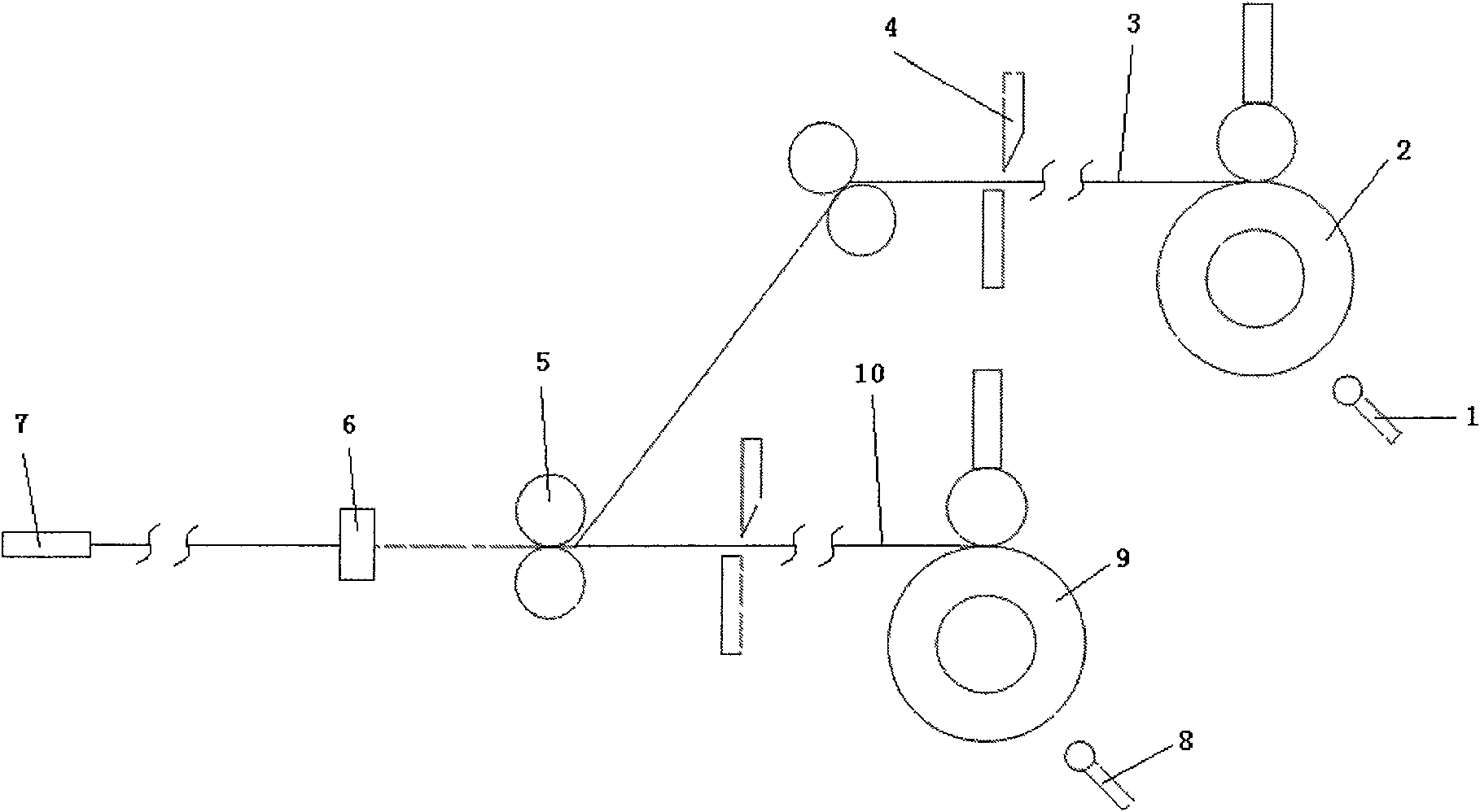

[0029] In order to understand the method provided by the present invention, first according to figure 1 Describe the structure of the inlet section of the cold rolling mill. The entrance section of the cold-rolling unit includes an entrance section double uncoiling system, scissors 4, common section pinch rolls 5, a welding machine 6, a looper 7 and an automatic control system 11 for controlling the entrance section of the cold-rolling unit; The uncoiling system includes No. 1 uncoiler 2 and No. 2 uncoiler 9, as well as idler roller 1 and idler 8 on the lower side of the uncoiler; steel strip 3 is connected to No. 1 uncoiler 2, and steel strip 10 is connected to No. 2 uncoiler 9 , through the scissors 4 and the pinch roller 5 of the common section to the welding machine 6 for welding, and finally to the looper 7 for punching, and the strip is temporar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com