Method for preparing mould cover of carbon block on anode of heterogeneous edge table in use for electrolyzing aluminum

A technology for anode carbon block and aluminum electrolysis, which is applied in the field of metallurgical electrolysis, can solve the problems of high anode gross consumption, heavy residual electrode weight, anodization, etc., and achieves the effect of less investment and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention are given below with reference to the accompanying drawings, which are used to further describe the structure of the present invention, and the specific implementation of the present invention is not limited to the following examples.

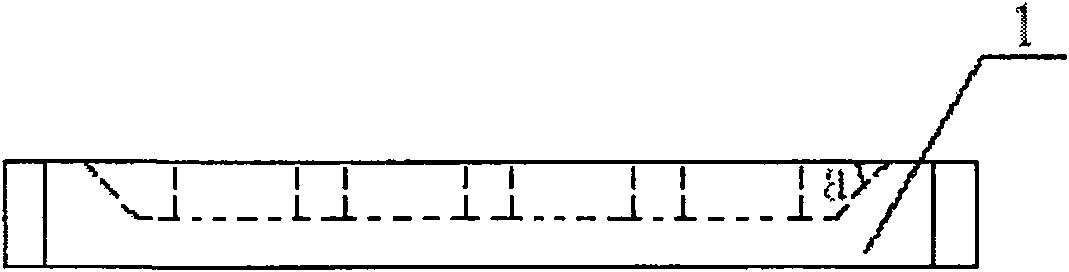

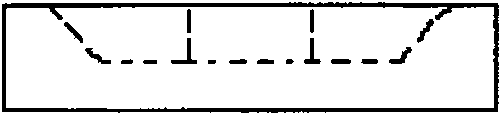

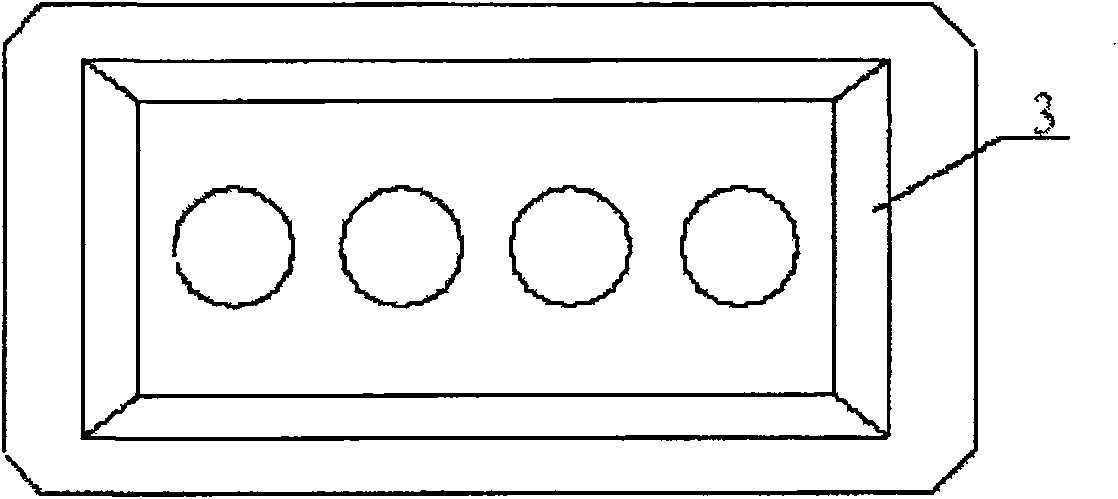

[0016] Reference to the preparation method of the special-shaped prism anode carbon block mold cover for aluminum electrolysis in this embodiment Figure 4 , 5 , 6, including the following steps:

[0017] First, measure the dimensions of the corners of the original anode carbon block quadrangular platform-shaped forming mold cover 1. According to the measured size, use 45# steel to plan out the special-shaped additional iron 2, and weld and attach it to the two small sides 3 of the mold cover. Transform the 45-degree angle on the two small sides of the mold cover 1 into a 35-degree angle by using the method, and measure and calculate the slope angle of the mold cover to be consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com