Cross-linked three D reticular supertine oil absorption fibre and its preparation method and application

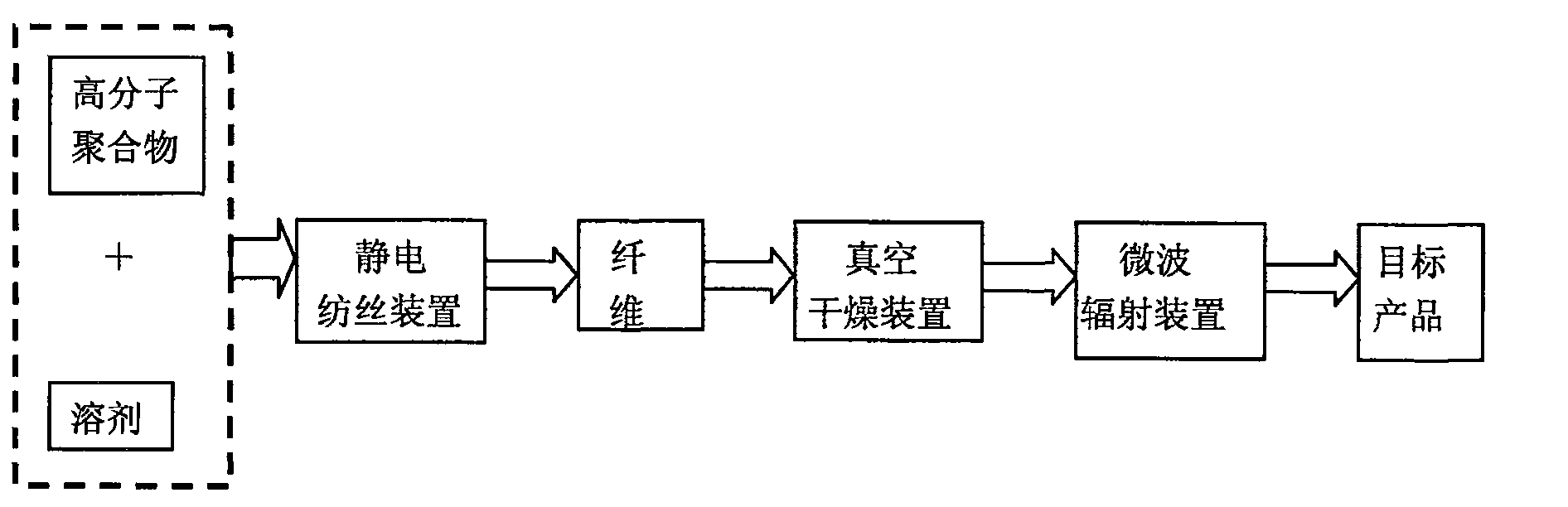

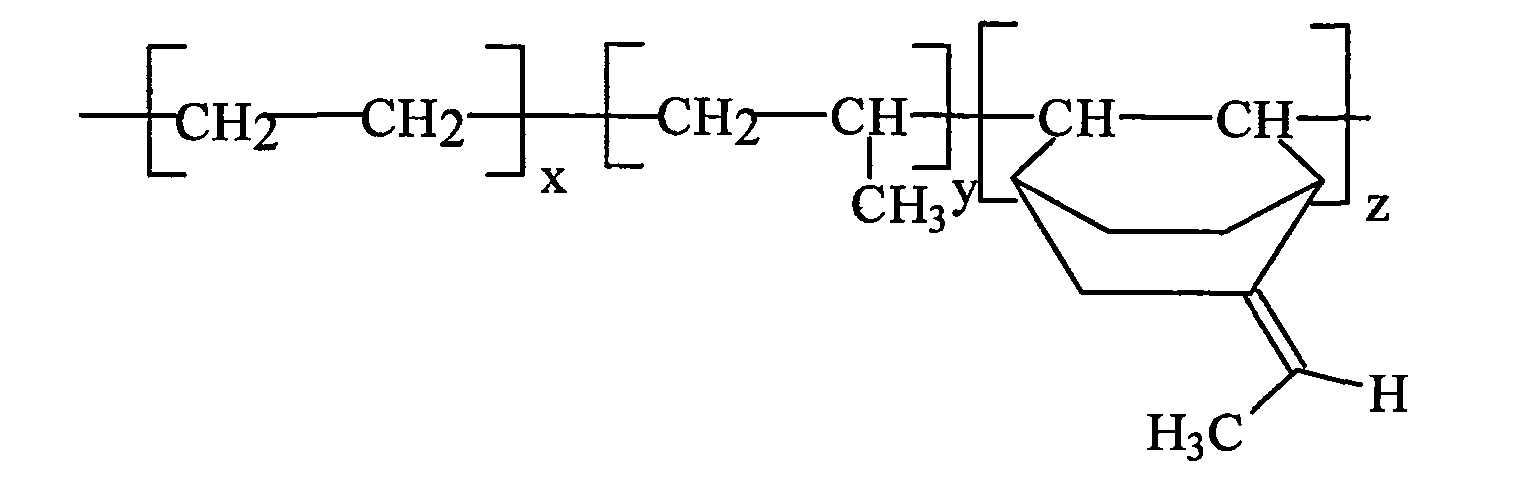

A technology of oil-absorbing fiber and three-dimensional network, which is applied in the field of cross-linked three-dimensional network ultra-fine oil-absorbing fiber and its preparation, and achieves the effects of wide application prospects, good controllability and repeatability, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

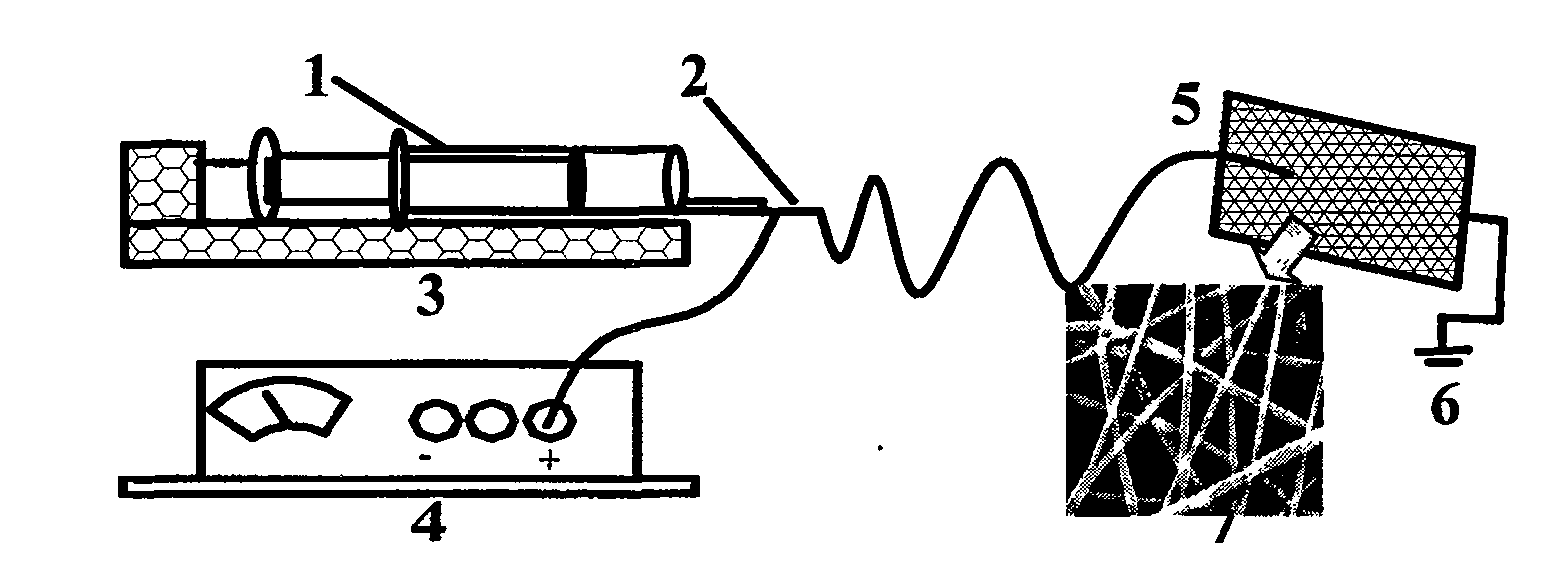

[0043] (1) Prepare 10 ml of tetrahydrofuran / cyclohexane solution of 6% ethylene-propylene-diene rubber in a concentration of 6%, wherein the volume ratio of tetrahydrofuran / cyclohexane is 4:1, and stir at 60° C. for 24 hours to obtain a uniform solution , Transparent polymer solution, after cooling to room temperature, place it for 4 hours for defoaming.

[0044] (2) Take about 5 milliliters of the above-mentioned polymer solution, put it into a liquid storage device, remove air, and connect a spinneret (aperture 1.2 mm). Connect the spinneret to the positive pole of the high voltage power supply. Install a 10 cm x 10 cm aluminum foil collection device with a temperature of 30 °C. The collection device is grounded. Adjust the distance between the spinneret and the collecting device to be 16 cm. The ambient temperature for spinning is 30°C, including the temperature of the solution in the liquid storage device and the temperature of the collecting device are both 30°C.

[0...

Embodiment 2

[0049] (1) Prepare 10 ml of tetrahydrofuran solution of EPDM rubber with a mass percent concentration of 6%, stir at 60° C. for 24 hours to obtain a uniformly dissolved and transparent polymer solution, cool to room temperature and place for 4 hours for defoaming.

[0050] (2) Take about 5 milliliters of the above-mentioned polymer solution, put it into a liquid storage device, remove air, and connect a spinneret (aperture 1.2 mm). Connect the spinneret to the positive pole of the high voltage power supply. Install a 10 cm x 10 cm aluminum foil collection device with a temperature of 30 °C. The collection device is grounded. Adjust the distance between the spinneret and the collecting device to be 18 cm. The ambient temperature for spinning is 30°C, including the temperature of the solution in the liquid storage device and the temperature of the collecting device are both 30°C.

[0051] (3) Turn on the high-voltage power supply, adjust the voltage to 15Kv, and the air veloc...

Embodiment 3

[0055] (1) Prepare 10ml of tetrahydrofuran / xylene solution of EPDM rubber with a mass percentage concentration of 4%, wherein the volume ratio of tetrahydrofuran / xylene is 5:1, and stir at 60°C for 24 hours to obtain a uniform and transparent solution The polymer solution was cooled to room temperature and placed for 4 hours for degassing.

[0056] (2) Take about 5 milliliters of the above-mentioned polymer solution, put it into a liquid storage device, remove air, and connect a spinneret (aperture 1.2 mm). Connect the spinneret to the positive pole of the high voltage power supply. Install a 10 cm x 10 cm aluminum foil collection device with a temperature of 30 °C. The collection device is grounded. Adjust the distance between the spinneret and the collecting device to be 20 cm. The ambient temperature for spinning is 30°C, including the temperature of the solution in the liquid storage device and the temperature of the collecting device are both 30°C.

[0057] (3) Turn o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com