Jackstone-type rockfill concrete construction method

A technology of rock-fill concrete and construction methods, which is applied in the direction of basic structure engineering, dams, building structures, etc., can solve the problems that the construction quality is greatly disturbed by human beings, the construction procedure is complicated, and the construction speed is slow, so as to achieve easy cycle construction and simplify construction. Improvement of construction procedures and construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

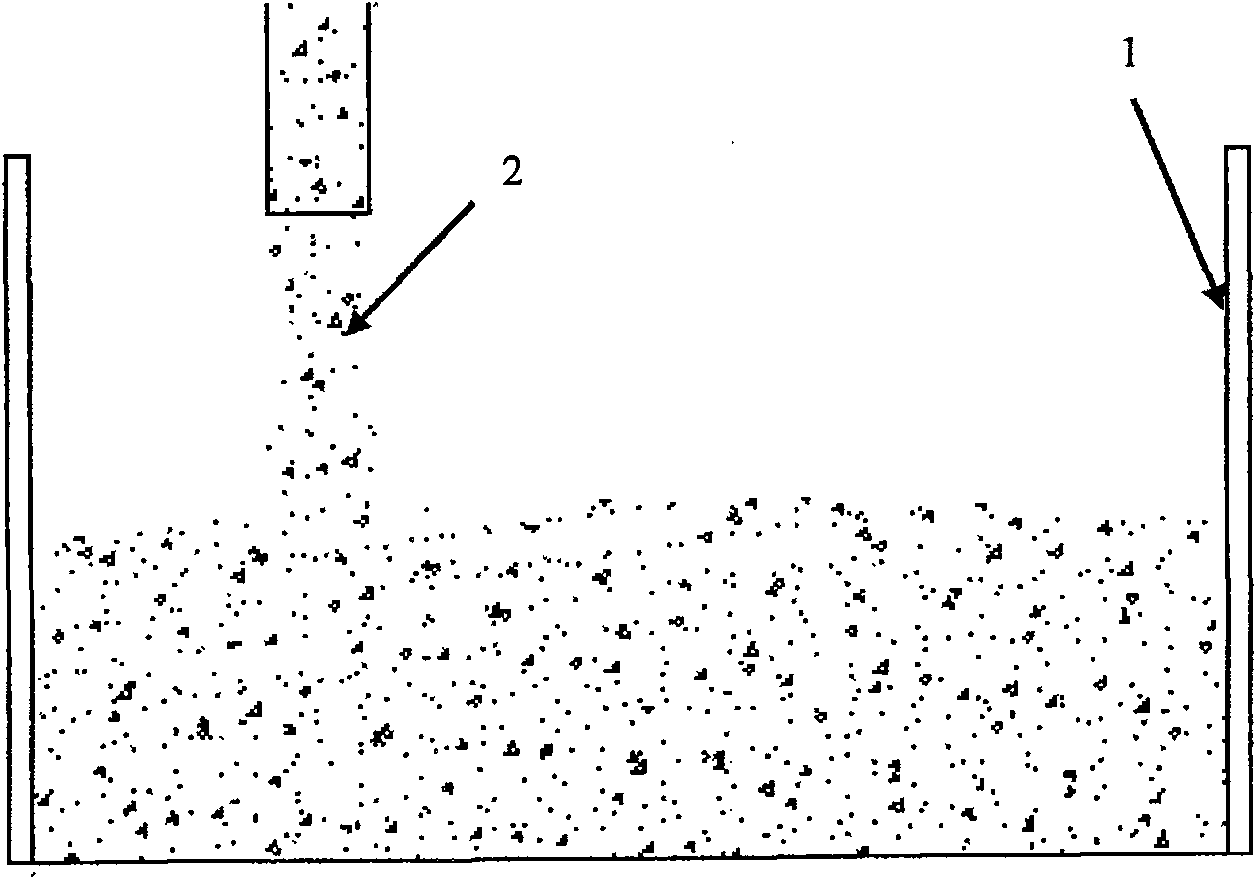

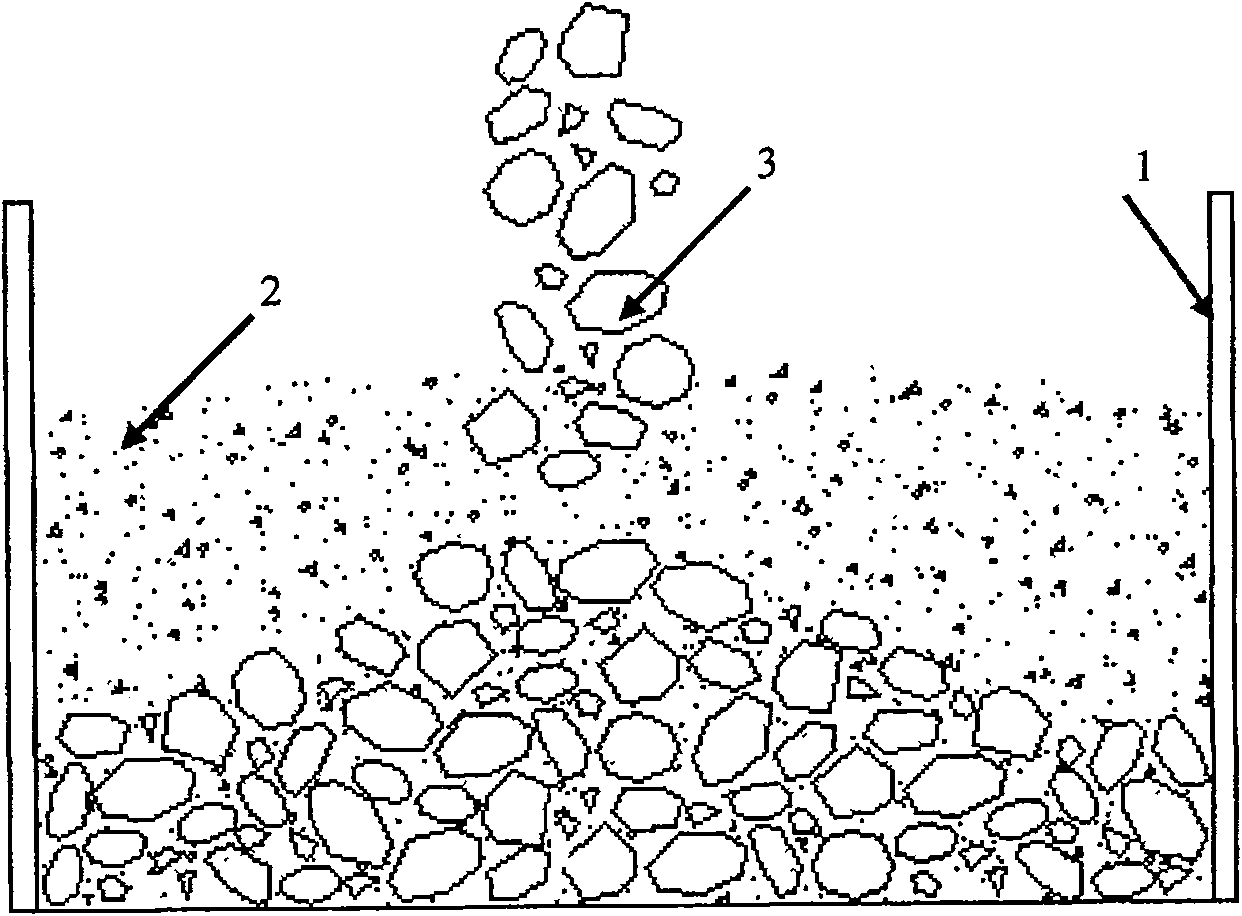

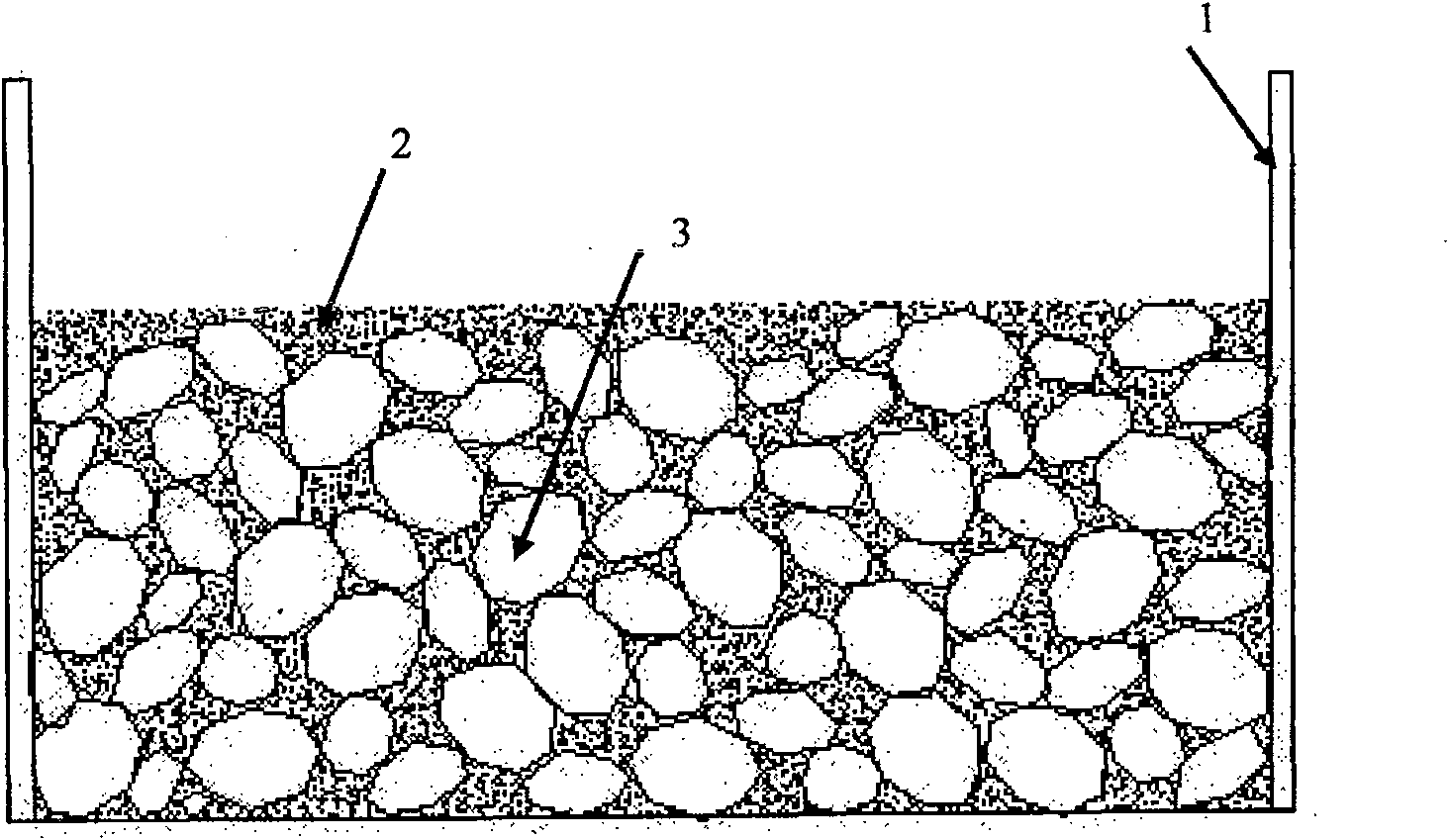

[0016] The present invention is based on the prior art. Firstly, self-compacting concrete is poured into the bin, and then blocks or pebbles of various particle sizes are thrown into the self-compacting concrete. The blocks or pebbles are in the self-compacting concrete under its own weight. Medium settlement and accumulation, eventually forming a complete and dense rockfill concrete. The specific implementation can be implemented as follows:

[0017] 1) Set up templates or substitutes for the silo surface where rockfill concrete needs to be poured. 1. The template substitutes can be closed structures such as masonry walls or concrete walls with certain rigidity and strength. The silo surfaces with natural barriers do not need to be installed with templates or Substitutes: For the warehouse surface that has barriers, no formwork is required, and closed structures such as masonry walls or concrete walls can be used instead of formwork.

[0018] 2) Pouring self-compacting concrete w...

specific Embodiment

[0025] In the specific implementation, the particle size of the rockfills used varies from 4cm to 80cm. There are both blocks and pebbles in the rockfills. The grain shape is mostly massive, containing long rockfills, and the number is small. The particle size distribution is uneven. The self-compacting concrete can be poured into the injection bin by pumping, laundering, free fall, etc. After pouring the self-compacting concrete about 1m later, use dump trucks, bulldozers, excavators and other equipment to quickly remove a large number of stones Pour the self-compacting concrete evenly into the self-compacting concrete until the self-compacting concrete is filled; then continue pouring the self-compacting concrete, and then throw stones to realize the circular construction. The self-compacting concrete with a slump of 240~260mm, an expansion degree of 450~650mm, and a V-shaped funnel passing time of 20s~50s is used for pouring. The pouring method adopts pumping into the warehouse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com