Probe measurement device and system

A probe measurement and probe head technology, applied in the field of probe measurement cards, can solve problems such as increased test costs, insufficient probe card area, and shortened life of probe cards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

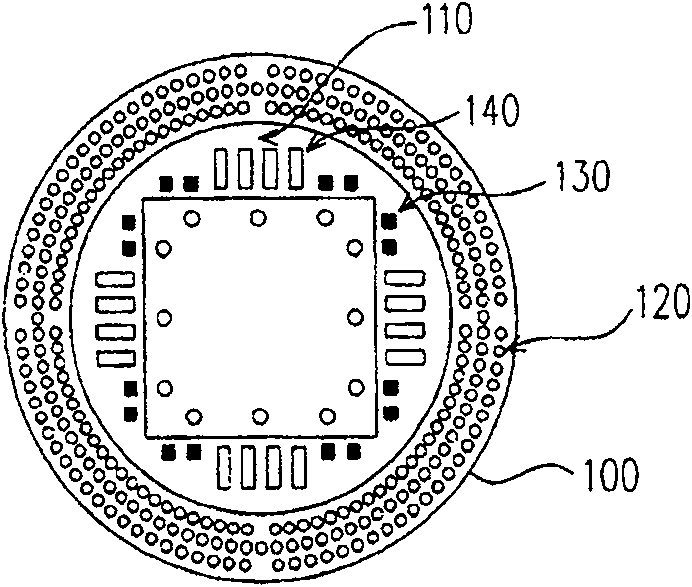

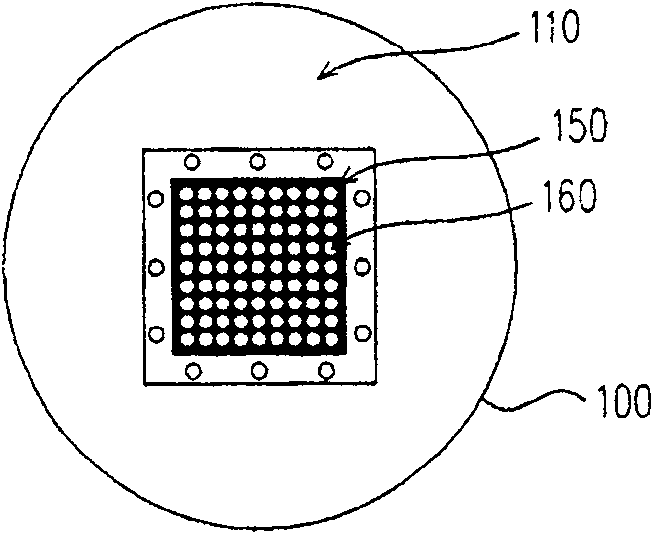

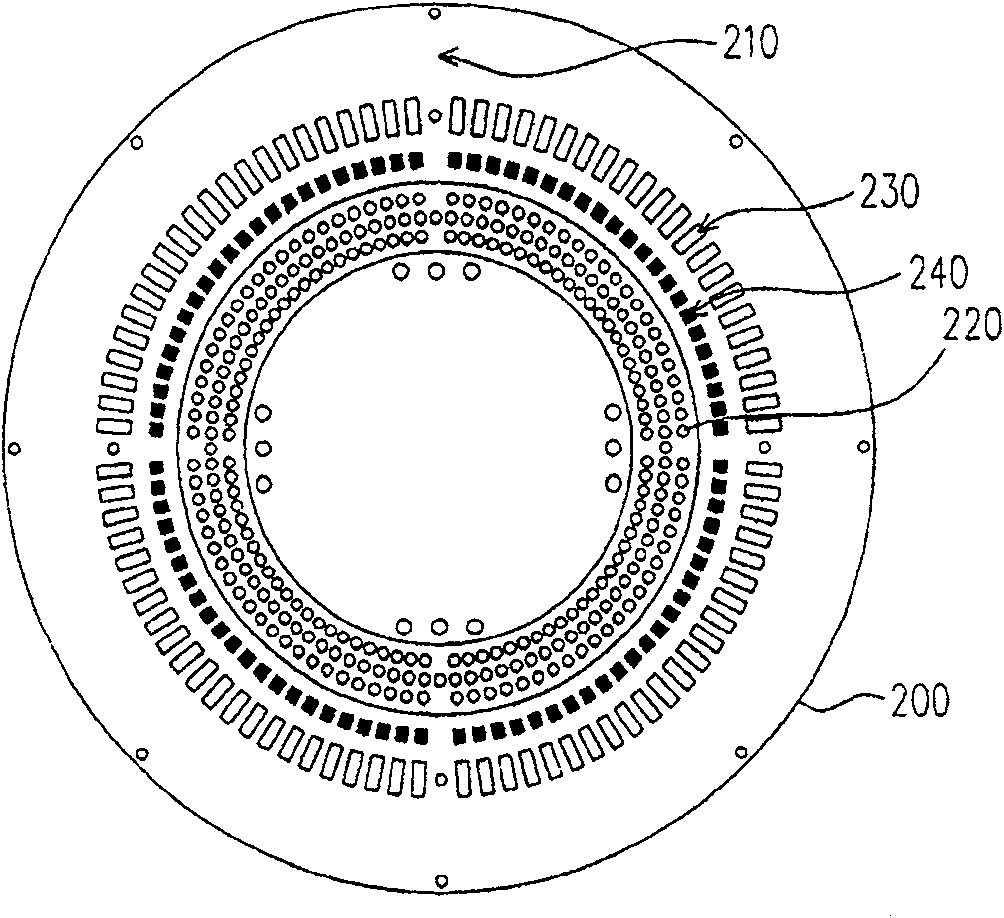

[0041] Figure 2a with 2b It is a layout diagram of a probe measuring device according to a preferred embodiment of the present invention. Please refer to Figure 2a with 2b In this embodiment, the area of the circuit board of the traditional probe card is increased, and the layout of each test element on the circuit board is changed at the same time, so that the number of probe heads of the probe card can be increased without changing the test motherboard. , so as to achieve the purpose of improving the test efficiency.

[0042] Such as Figure 2a with 2b As shown, the circuit board 210 of the probe measuring device 200 of the present embodiment is compared with the circuit board 110 of the existing probe card (such as Figure 1a with1b shown) has been enlarged and divided into upper and lower sides, where Figure 2a Shown is the top half, Figure 2b Bottom half shown. exist Figure 2a Among them, a plurality of spring contacts 220 are arranged on the circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com