Boiler flyash carbon content on-line testing apparatus

A technology of fly ash carbon content and detection device, which is applied in the direction of removing certain components for weighing and using combustion for chemical analysis, etc. The accuracy of carbon measurement cannot be guaranteed, etc., to achieve the effect of accurate basis and guidance, high measurement accuracy, and high sampling representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

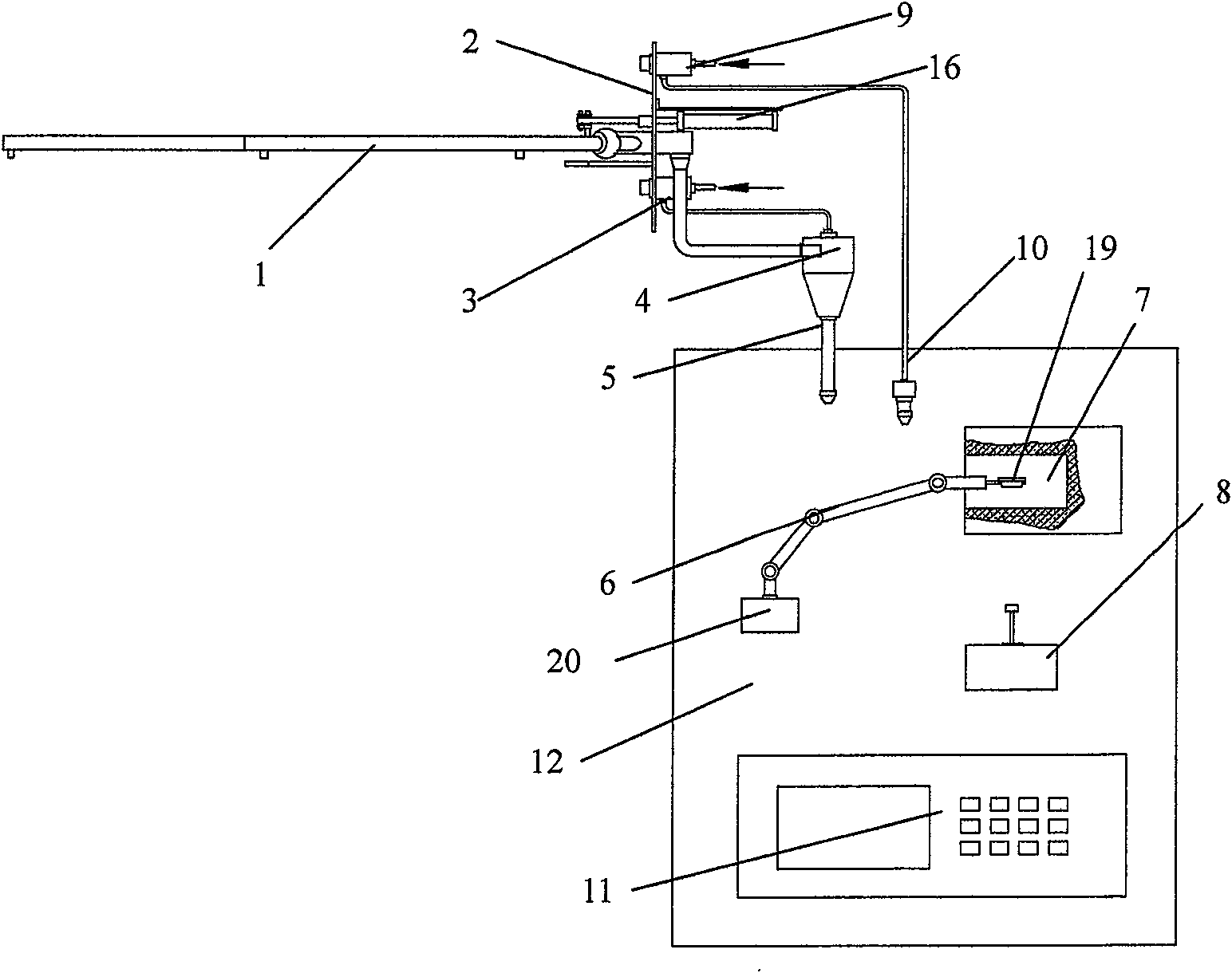

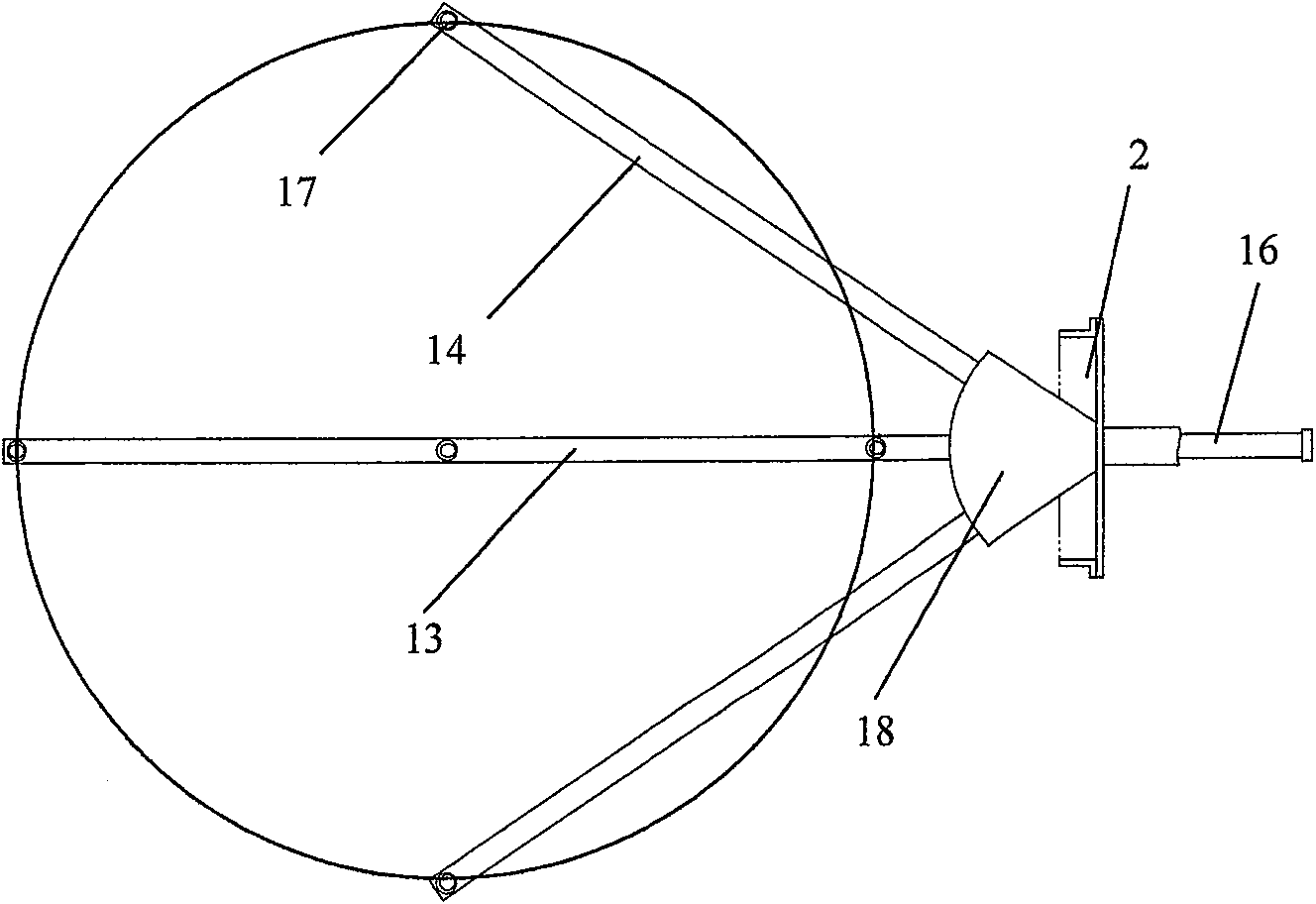

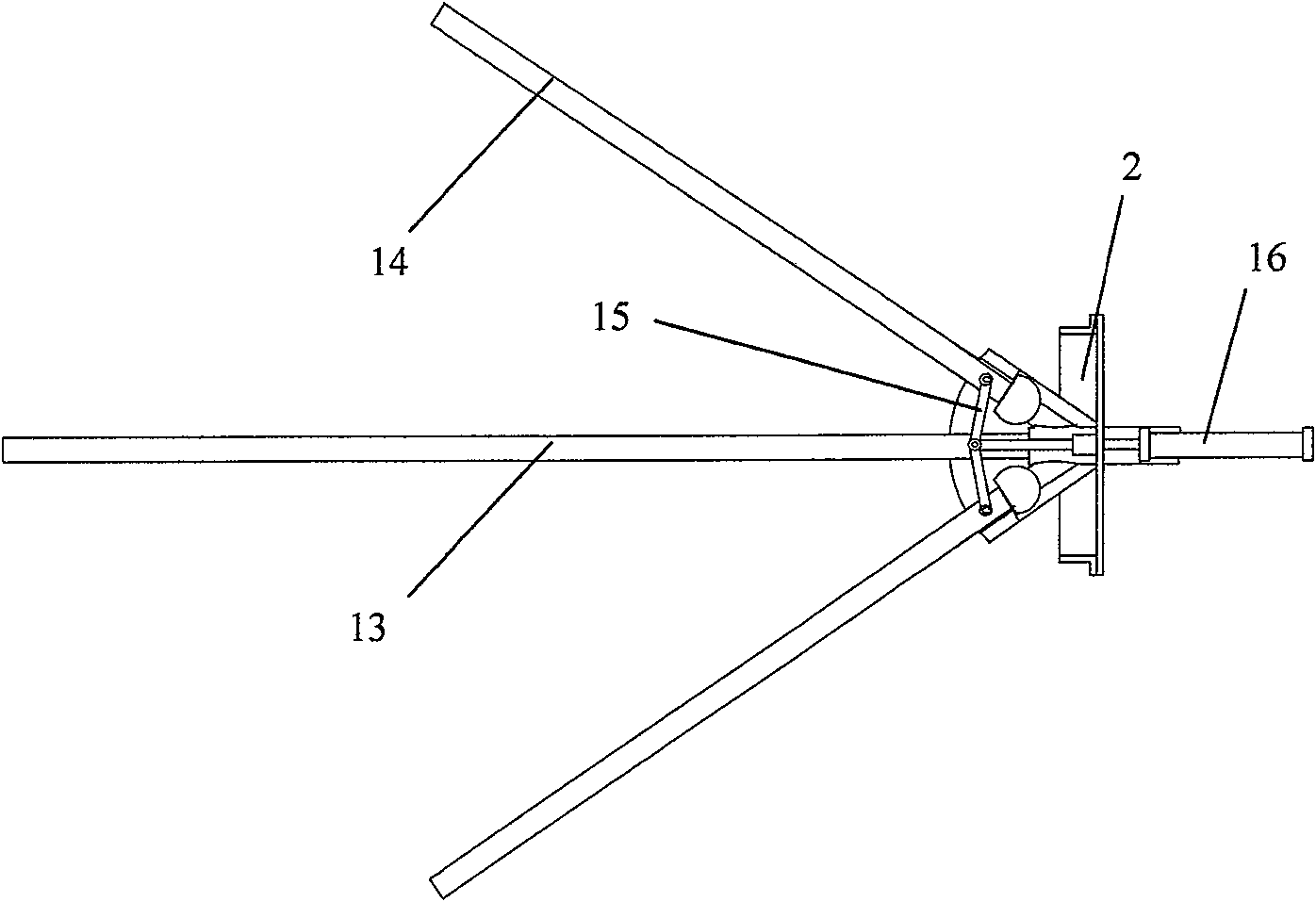

[0015] Such as figure 1 As shown, the on-line detection device for the carbon content of boiler fly ash includes a split-type fork-shaped multi-point sampler 1, a mounting plate 2, a first vacuum generator 3, a cyclone separator 4, an ash collection tube 5, a manipulator 6, and a high-power microwave Source 7, load cell 8, second vacuum generator 9, ash discharge pipe 10, host machine 11 and measurement box 12. The split type fork-shaped multi-point sampler 1, the first vacuum generator 3 and the second vacuum generator 9 are fixed on the mounting plate 2; the cyclone separator 4 is connected with the split-type fork-shaped multi-point sampler 1 and the first vacuum generator respectively. The device 3 and the ash collection pipe 5 are connected; the second vacuum generator 9 is connected with the ash discharge pipe 10 . The other outlet of the ash collection pipe 5 and the ash discharge pipe 10 is installed in the measurement box 12; the measurement box 12 is also equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com