Lead accumulator

A technology for lead-acid batteries and storage batteries, which is applied in the field of lead-acid batteries and can solve problems such as electrolyte overflow, flying out, and damage to gas discharge functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, the present invention will be described in detail through one embodiment, but the present invention is not limited to this.

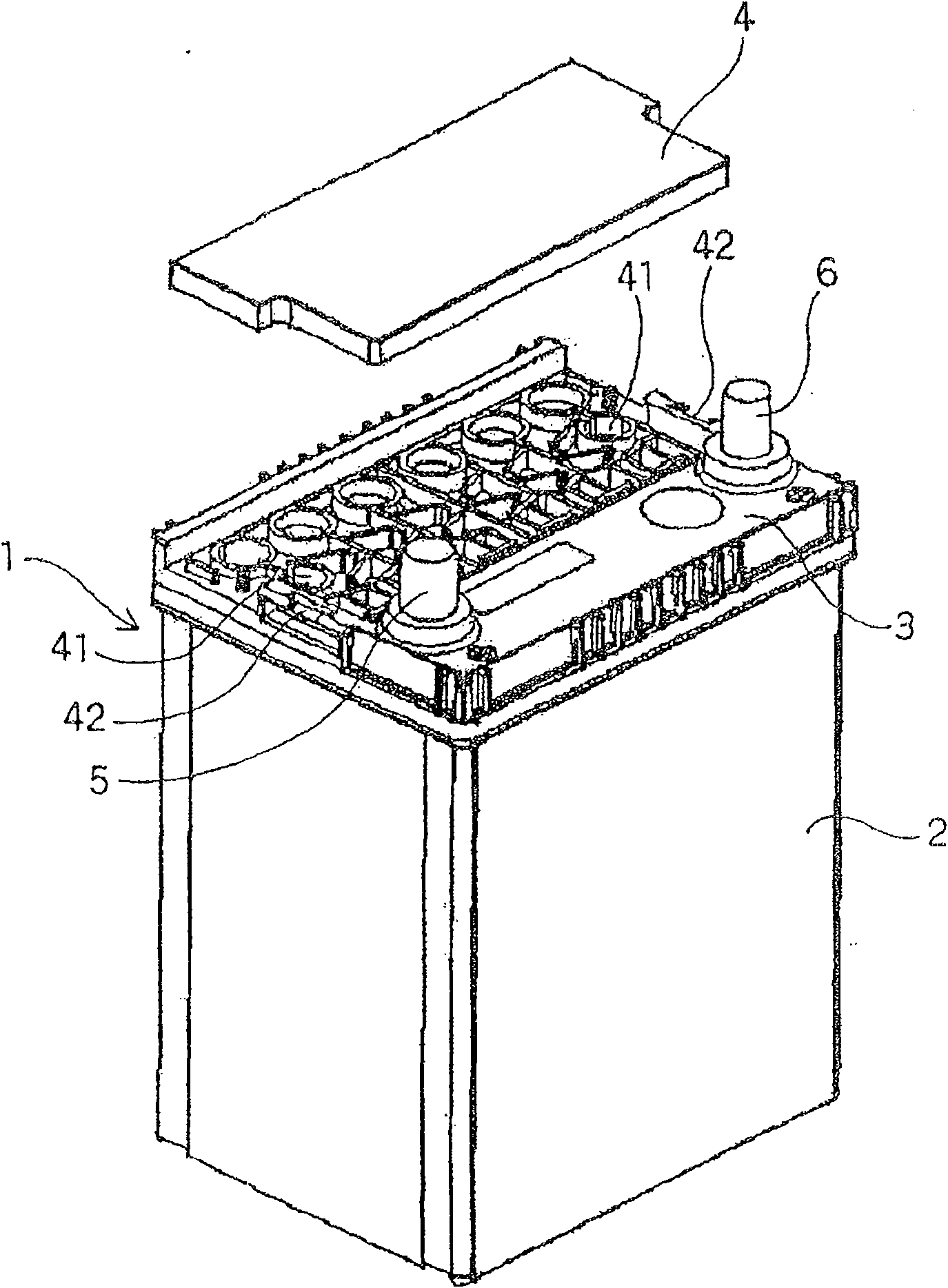

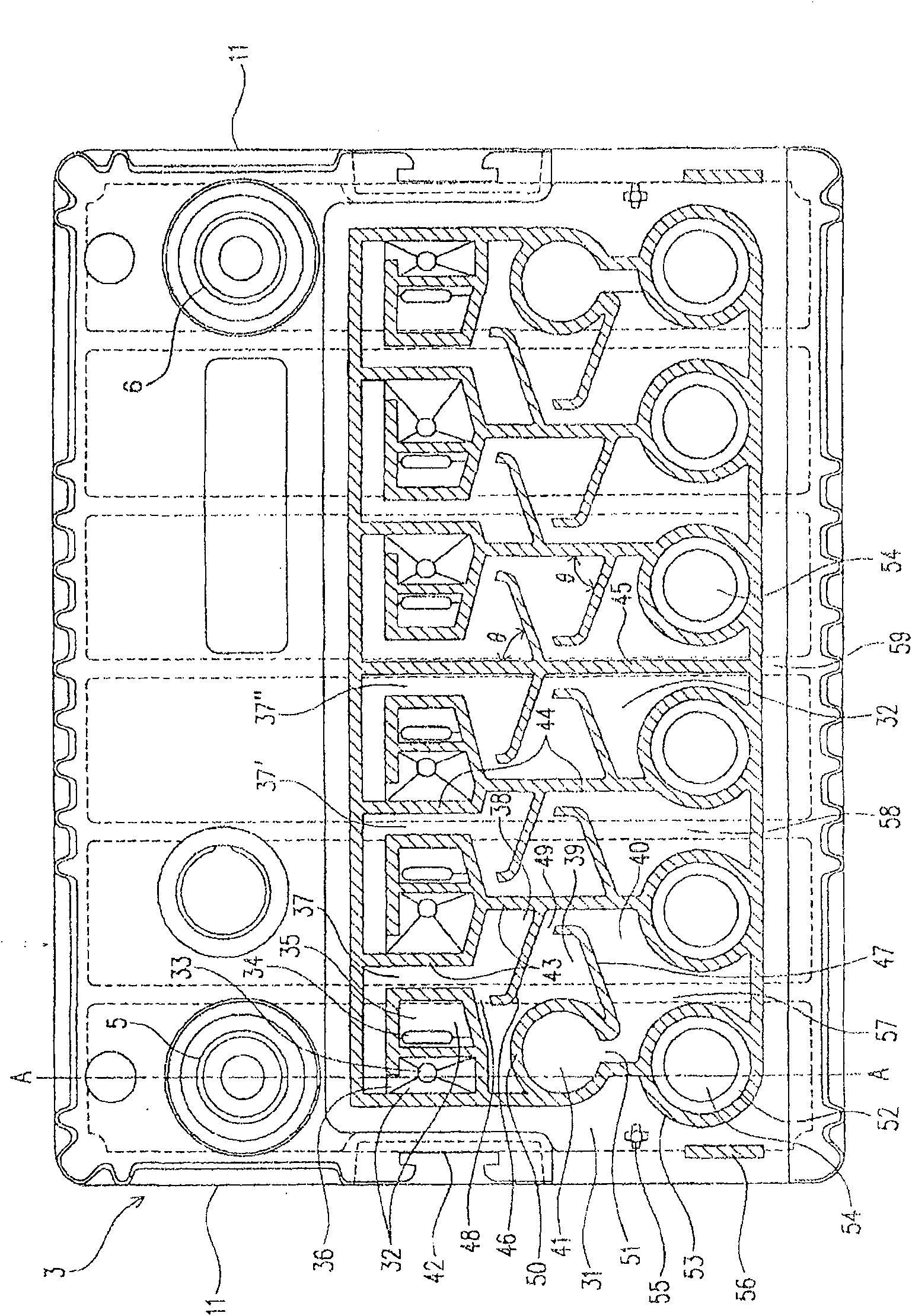

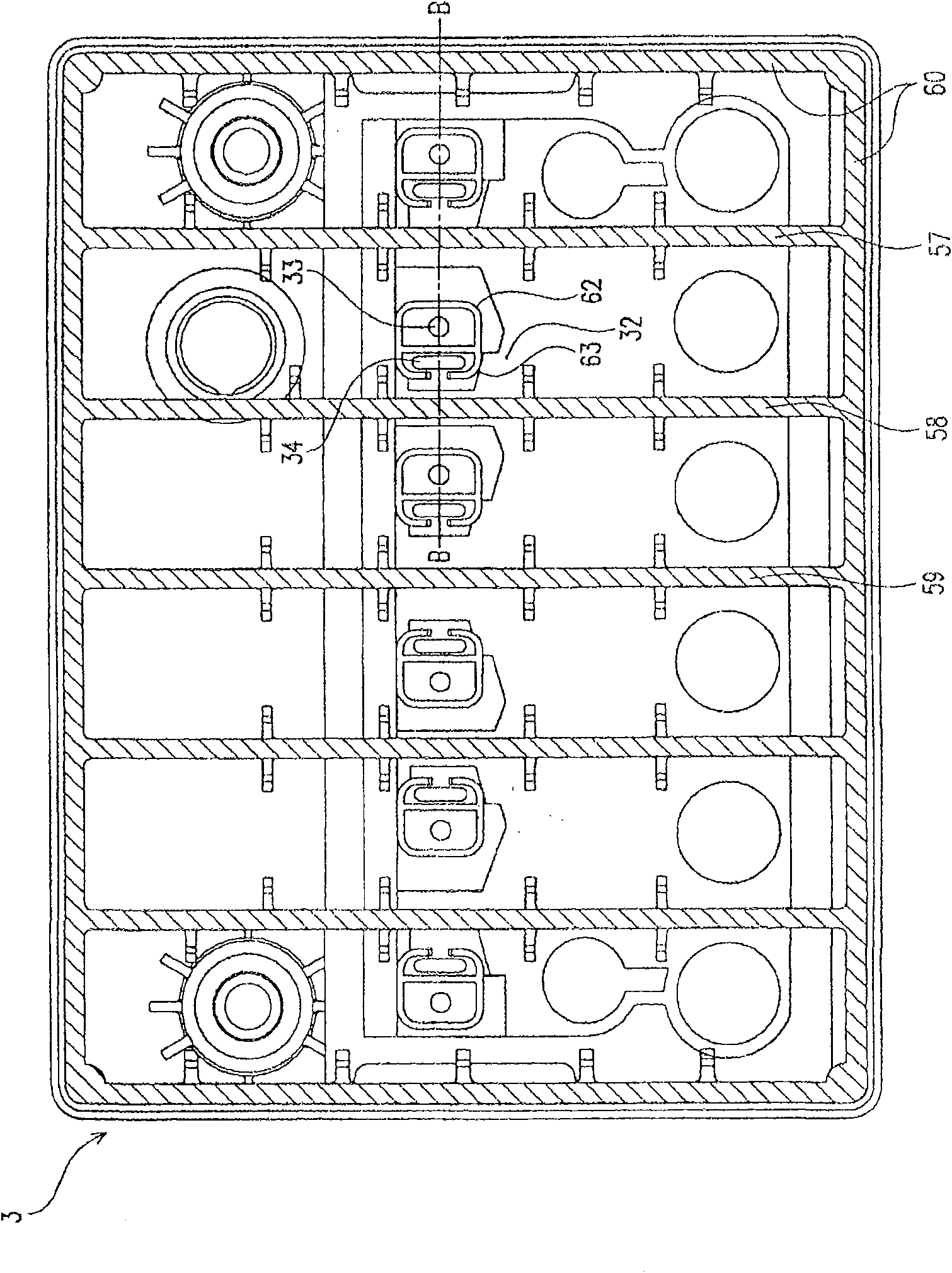

[0060] figure 1 It is a perspective view of the six-cell integrated lead storage battery 1 according to an embodiment of the present invention when viewed obliquely from above. figure 1 2 is the battery case, the inside of which is divided into six unit cells by five partition walls (not shown) arranged in parallel with the short sides of the battery side, and each unit cell is housed by a set of positive plates, negative plates and partitions. An electrode plate group composed of plates and an electrolyte composed of dilute sulfuric acid (not shown). figure 1 3 is the middle cover installed on the upper surface of the battery case 2, and 4 is the upper cover installed in the recess of the middle cover 3. The battery case 2, the middle cover 3, and the upper cover 4 are all polypropylene molded bodies. The upper end of the side wall (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com