Cargo pump apparatus for liquid cargo ship

A pump device and cargo technology, which is applied to cargo handling equipment, bulk cargo, ship hulls, etc., can solve the problems of increased personnel costs and equipment costs, excess equipment, etc., and achieve the effect of reducing operating costs and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

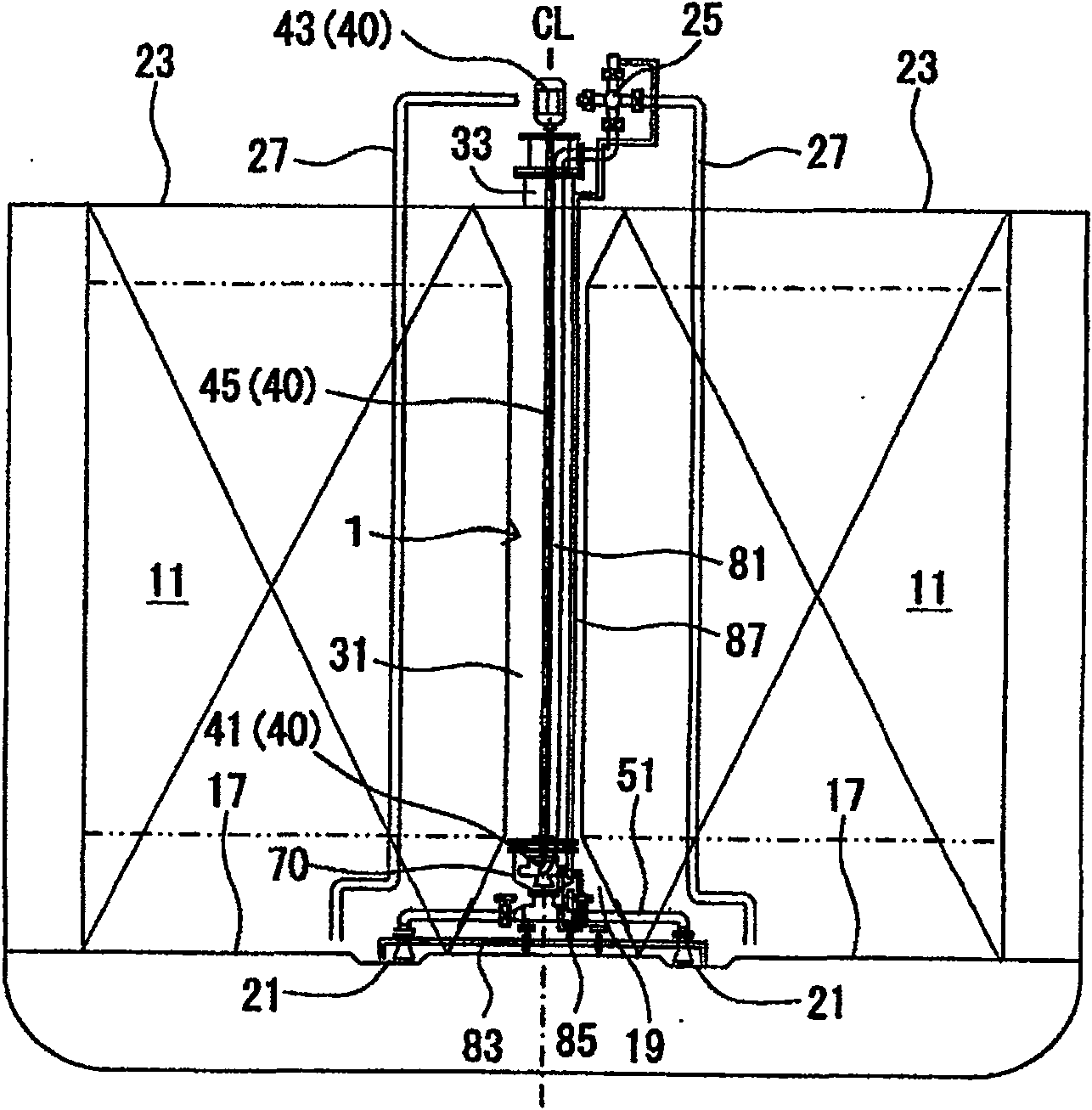

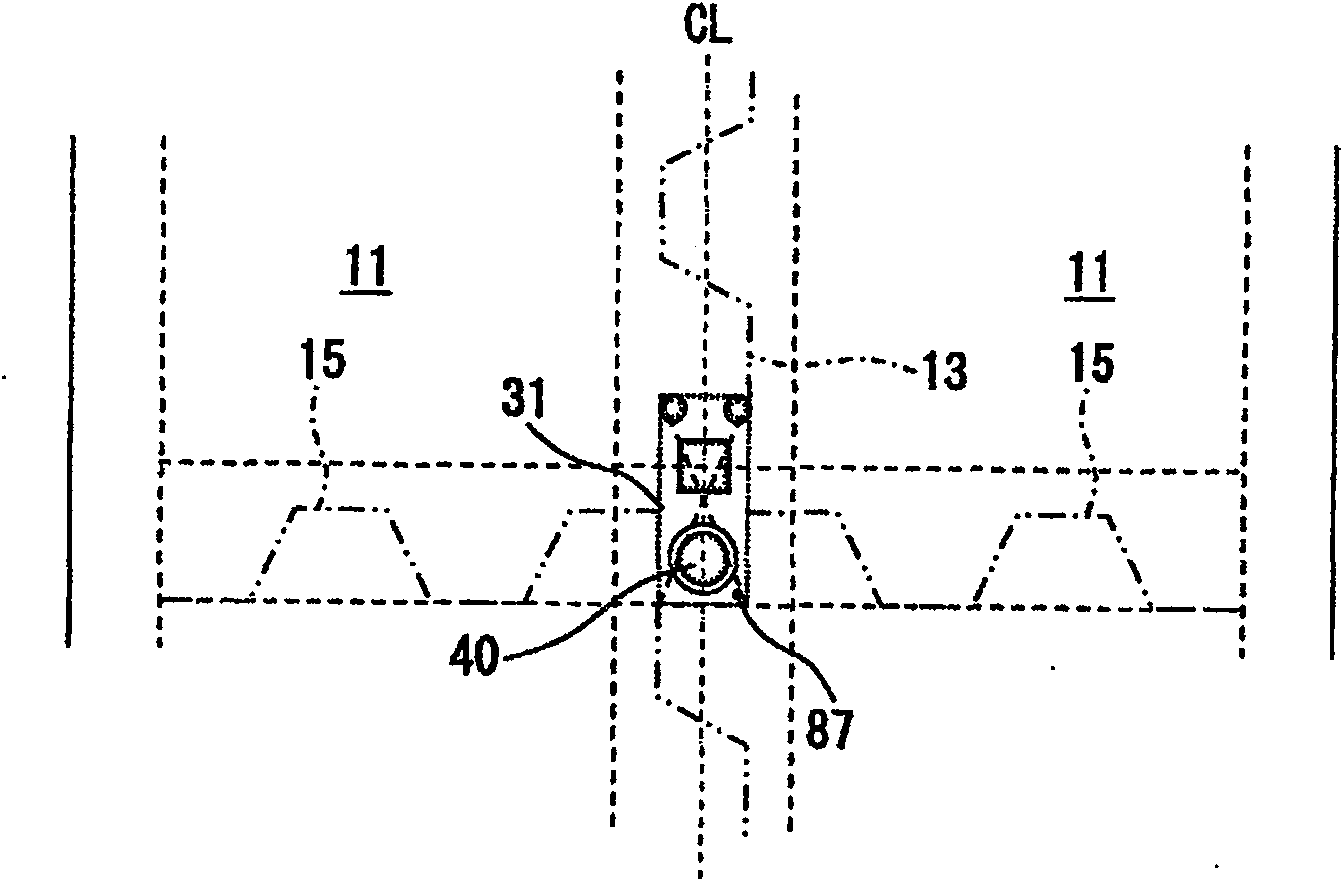

[0069] First, based on figure 1 as well as figure 2 The outline of the cargo pump device and the attached residual oil recovery device according to Embodiment 1 will be described, and then based on image 3 as well as Figure 4 The cargo pump device according to the first embodiment will be described.

[0070] exist figure 2 In the figure, the upper part of the drawing is the bow side, and the lower part of the drawing is the stern side, such as figure 2 As shown, the cabin 11 is formed by liquid-tight partitioning by a central bulkhead 13 erected along the centerline (CL) of the cargo ship and a plurality of transverse bulkheads 15 vertically erected to the central bulkhead 13 . Moreover, the central partition wall 13 and the transverse partition wall 15 are arranged on the bottom vertical support pier 19 and the lower part of the transverse support pier (pedestal) which are approximately isosceles trapezoidal in cross-section, and the central partition wall 13 and th...

Embodiment 2

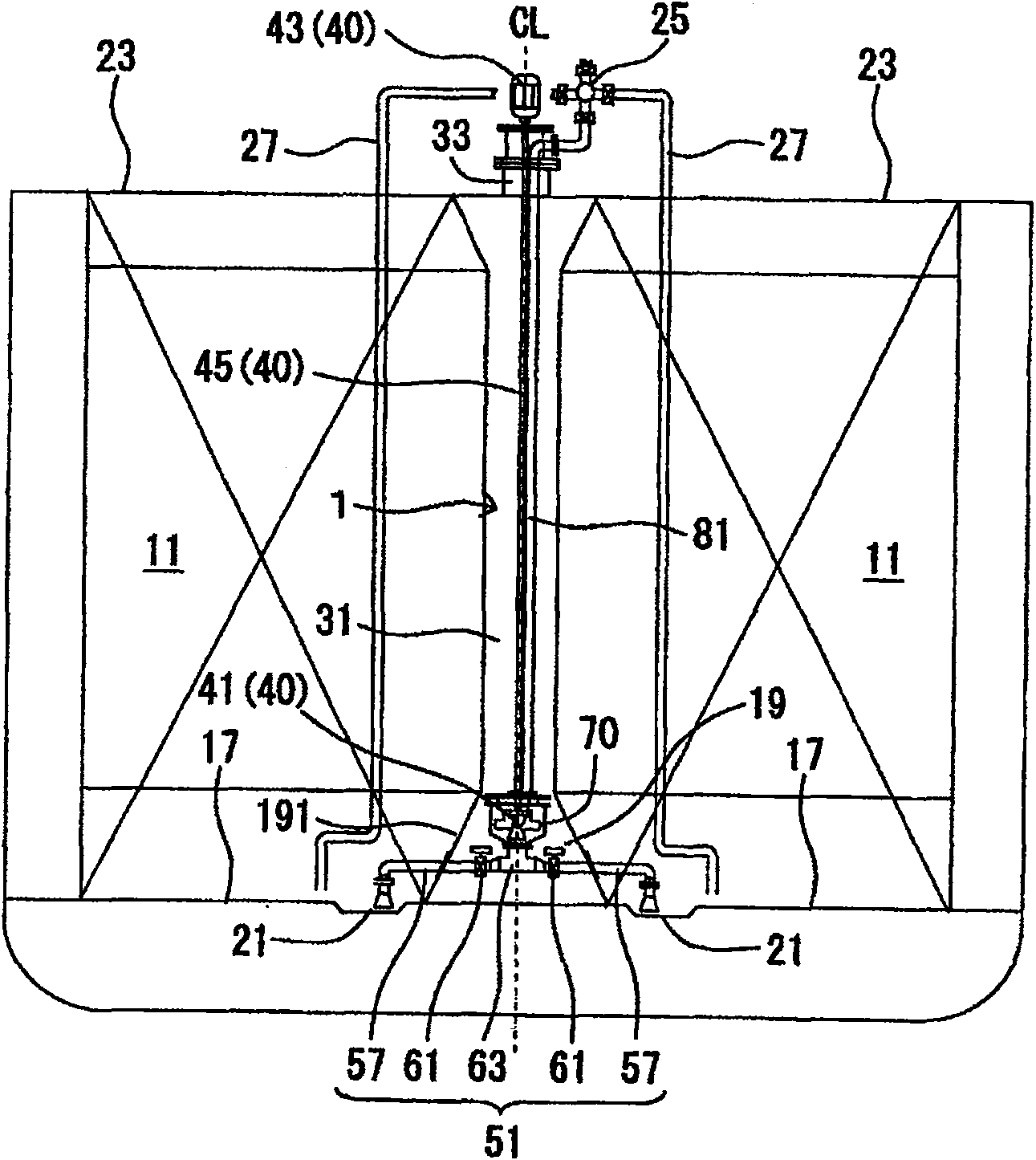

[0086] Next, based on Figure 5 as well as Image 6 The cargo pump device related to the second embodiment will be described. Since the structure of the cabin 11, the central partition 13, the transverse partition 15, the cargo pump room 31, and the hatch portion 33 are the same as those in the first embodiment, the description thereof will be omitted, and it is attached to the cargo pump device. The structure and effect of the residual oil recovery device of 2 are also the same as those of the first embodiment, so the description thereof will be omitted.

[0087] The cargo pump device 2 is mainly composed of a deep well pump 40 arranged in each cargo pump chamber 31, a cargo suction part 52 connected to the suction side of the deep well pump 40, and a cargo pump connected to the discharge side of the deep well pump 40. A discharge pipe 81 is formed.

[0088] The deep well pump 40 is composed of a motor part 43 and a pump part 41 connected to the motor part 43 via a drive sh...

Embodiment 3

[0096] Next, based on Figure 7 as well as Figure 8 The cargo pump device related to Embodiment 3 will be described. Since the structure of the cabin 11, central partition 13, transverse partition 15, cargo pump room 31, and hatch 33 is the same as that of Embodiment 1, its description will be omitted, and it is attached to the cargo pump device. The configuration and effects of the residual oil recovery device of 3 are also the same as those of Embodiment 1, so the description thereof will be omitted.

[0097] The cargo pump device 3 is mainly composed of a deep well pump 40 configured in each cargo pump chamber 31, a cargo suction portion 53 connected to the suction side of the deep well pump 40, and a cargo pump connected to the discharge side of the deep well pump 40. A discharge pipe 81 is formed.

[0098] The deep well pump 40 is composed of a motor part 43 and a pump part 41 connected to the motor part 43 via a drive shaft 45. The motor part 43 is fixed on the hatch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com