In-position cleaning method for town regenerated water plate type heat exchanger

A technology for plate heat exchangers and reclaimed water, which is applied to the types of heat exchangers, indirect heat exchangers, flushing, etc., can solve the problem of cleaning the flow and heat transfer performance of plate heat exchangers that cannot be achieved, and restricts the efficient recovery of urban reclaimed water heat. Use technology promotion and application, poor dirt stripping effect and other problems to achieve the effect of slowing down the rate of dirt regrowth, unaffected descaling effect, and high descaling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

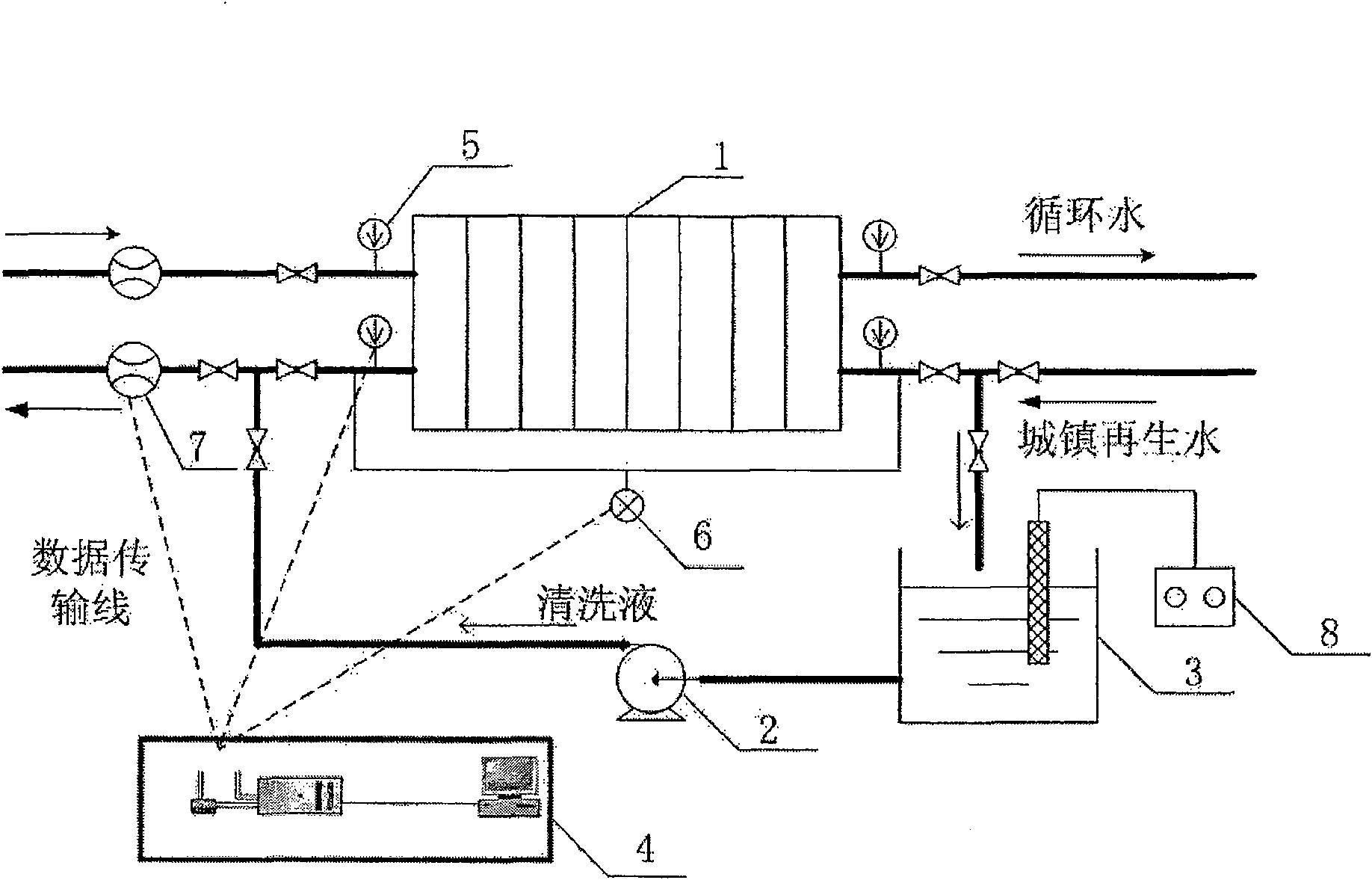

[0029] Example 1: Example of in-place cleaning of urban reclaimed water plate heat exchangers under heating conditions in winter

[0030] A water-source heat pump system that uses the secondary effluent of cities and towns as the cold and heat source, and uses plate heat exchangers to recover the low-level heat energy of the secondary effluent of cities and towns. In winter, the heating efficiency of the heat pump system decreased. After analysis, it was found that the secondary effluent was fouled in the plate heat exchanger. It was decided to use in-place cleaning technology to clean the plate heat exchanger.

[0031] 1. Overview of cleaning system

[0032] Circulating cleaning water tank volume: 100L

[0033] Plate heat exchanger material: stainless steel 304

[0034] Scaling situation: The dirt layer on the high temperature side of the plate surface is thicker, and the dirt layer on the low temperature side is thinner, and the scaling degree is relatively light.

[0035...

Embodiment 2

[0047] Example 2: Example of in-place cleaning of urban reclaimed water plate heat exchangers under cooling conditions in summer

[0048] A water-source heat pump system that uses the secondary effluent of cities and towns as the cold and heat source, and uses plate heat exchangers to recover the low-level heat energy of the secondary effluent of cities and towns. In summer, the cooling efficiency of the heat pump system dropped rapidly. After analysis, it was found that the secondary effluent was fouled in the plate heat exchanger. It was decided to use in-place cleaning technology to clean the plate heat exchanger.

[0049] 1. Overview of cleaning system

[0050] Circulating cleaning water tank volume: 100L

[0051] Plate heat exchanger material: stainless steel 316

[0052] Scaling situation: The surface of the plate is covered with mixed fouling mainly composed of microbial fouling from bottom to top, and the degree of fouling is relatively heavy.

[0053] 2. Cleaning m...

Embodiment 3

[0065] Example 3: An example of in-place cleaning of urban reclaimed water plate heat exchangers with serious fouling in summer cooling conditions

[0066] A water-source heat pump system that uses the secondary effluent of cities and towns as the cold and heat source, and uses plate heat exchangers to recover the low-level heat energy of the secondary effluent of cities and towns. In summer, the heat pump system operated continuously for one month, and the cooling efficiency dropped significantly. After analysis, it was found that the secondary effluent was fouled in the plate heat exchanger. It was decided to use in-place cleaning technology to clean the plate heat exchanger.

[0067] 1. Overview of cleaning system

[0068] Circulating cleaning water tank volume: 100L

[0069] Plate heat exchanger material: stainless steel 316

[0070] Scaling situation: The dirt layer on the surface of the plate is thicker, more viscous, strong adhesion, and the degree of scaling is very ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com