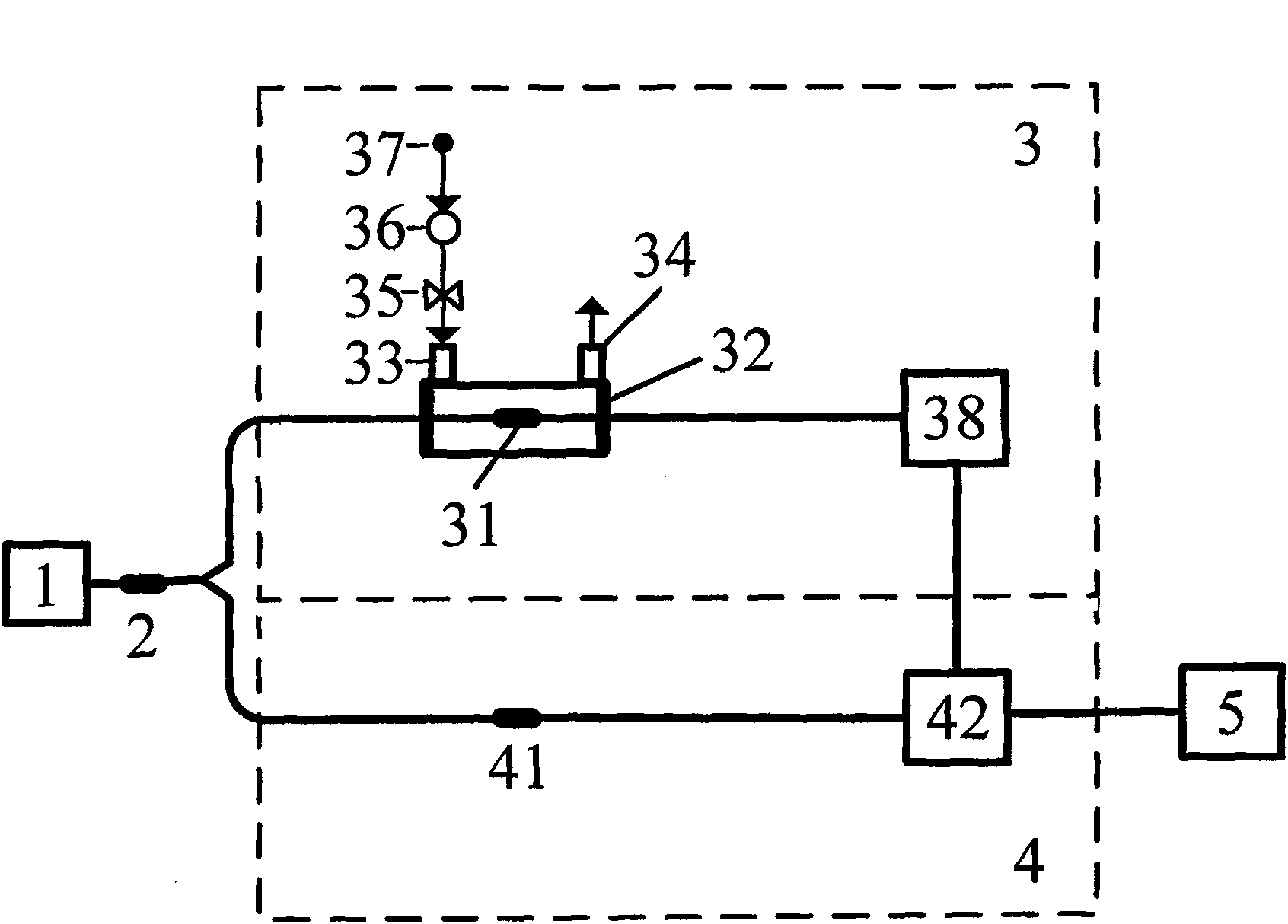

Optical fiber methane sensing system based on fiber core mismatch

A fiber core mismatch, sensing system technology, applied in the measurement of phase influence characteristics, etc., can solve the problems of difficult diffusion and migration of methane molecules, difficulty in compensating for optical signal fluctuations, large transmission loss over long distances, etc. Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

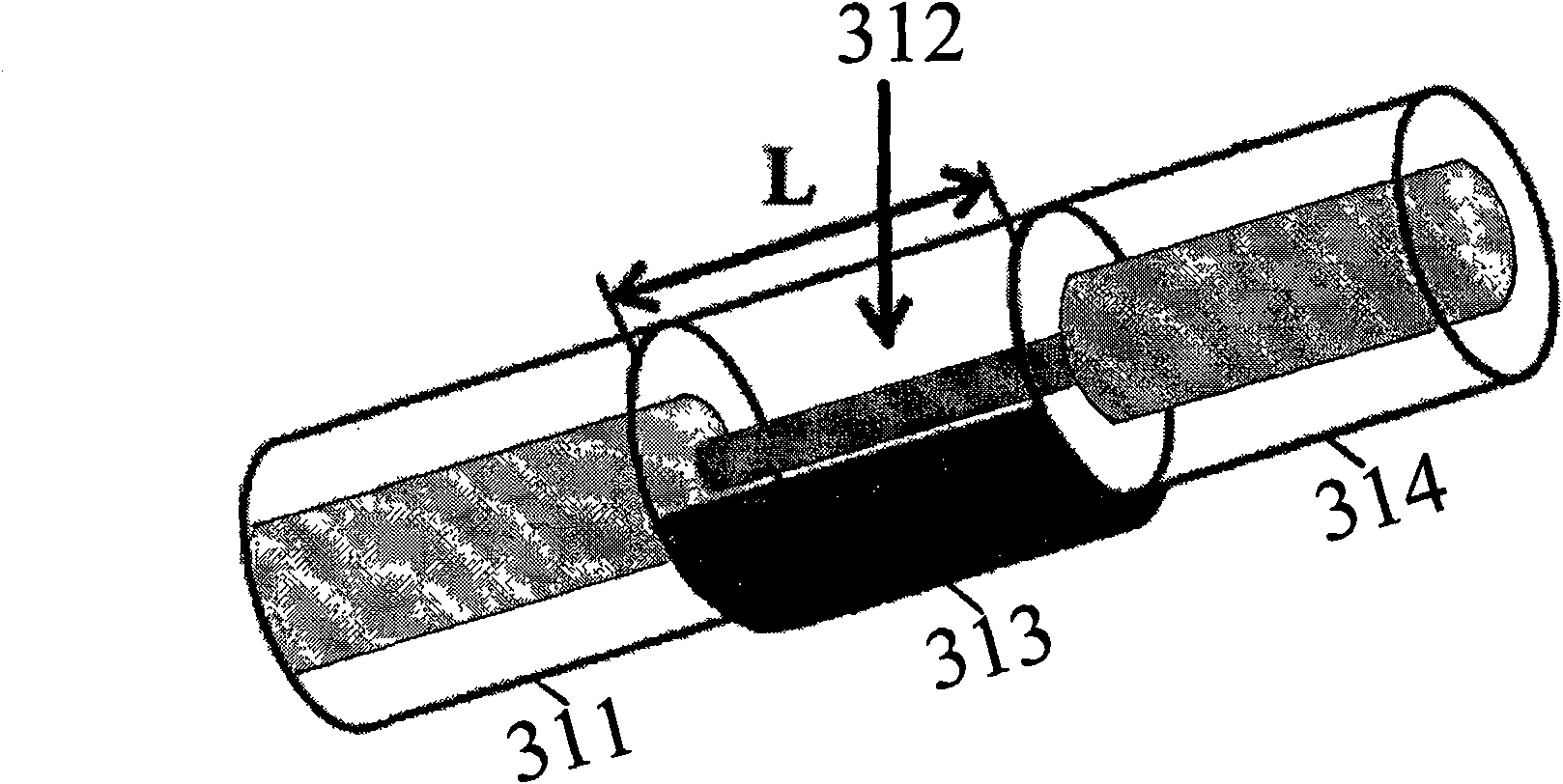

example 1

[0029] Example 1: First, a multimode fiber with a core diameter of 62.5 μm is selected to make a core mismatch sensor and as a transmission fiber. Within the selected concentration range, the known methane standard gas concentration ranges from 0.5% to 5%, which interact with the sensor respectively, and the normalized optical power output by the sensor increases with the increase of the methane gas concentration, and the normalized optical power is consistent with the methane gas concentration. There is a linear correlation between the concentrations, and the linear regression equation is:

[0030] s=kc+b

[0031] In the formula, c is the concentration of methane gas to be measured, s is the normalized optical power output by the sensor, k is the slope, and b is the intercept.

[0032] In the experiment, standard gases with known methane concentrations of 0.5, 1, 2, 3, 4, and 5% were first used for detection, and the normalized optical power s output by the corresponding sen...

example 2

[0033] Example 2: Select a multimode fiber with a core diameter of 50 μm to make a core mismatch sensor and as a transmission fiber. On the basis of Example 1, it is known that methane standard gas interacts with the sensor respectively, and the normalized optical power s output by the corresponding sensor is 1.0001, 1.0025, 1.0053, 1.0079, 1.0139, 1.0171 respectively, and the obtained linear regression equation is: s=0.0038 c+0.9981, correlation coefficient R 2 =0.9847, that is, k and b in the linear regression equation are 0.0038 and 0.9981 respectively. When the methane gas to be measured is in contact with the sensor, the normalized optical power s output by the sensor is 1.0118, the concentration of the methane gas to be measured is c=3.6%, the response speed is 42 seconds, and the recovery time is 45 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com