Bristle hair roll backwinding machine

A technology of rewinding machine and bristles, which is applied in the field of bristle processing and finishing, can solve the problems of high labor intensity, low process efficiency, harsh labor environment, etc., and achieves the effects of uniform and tight winding, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

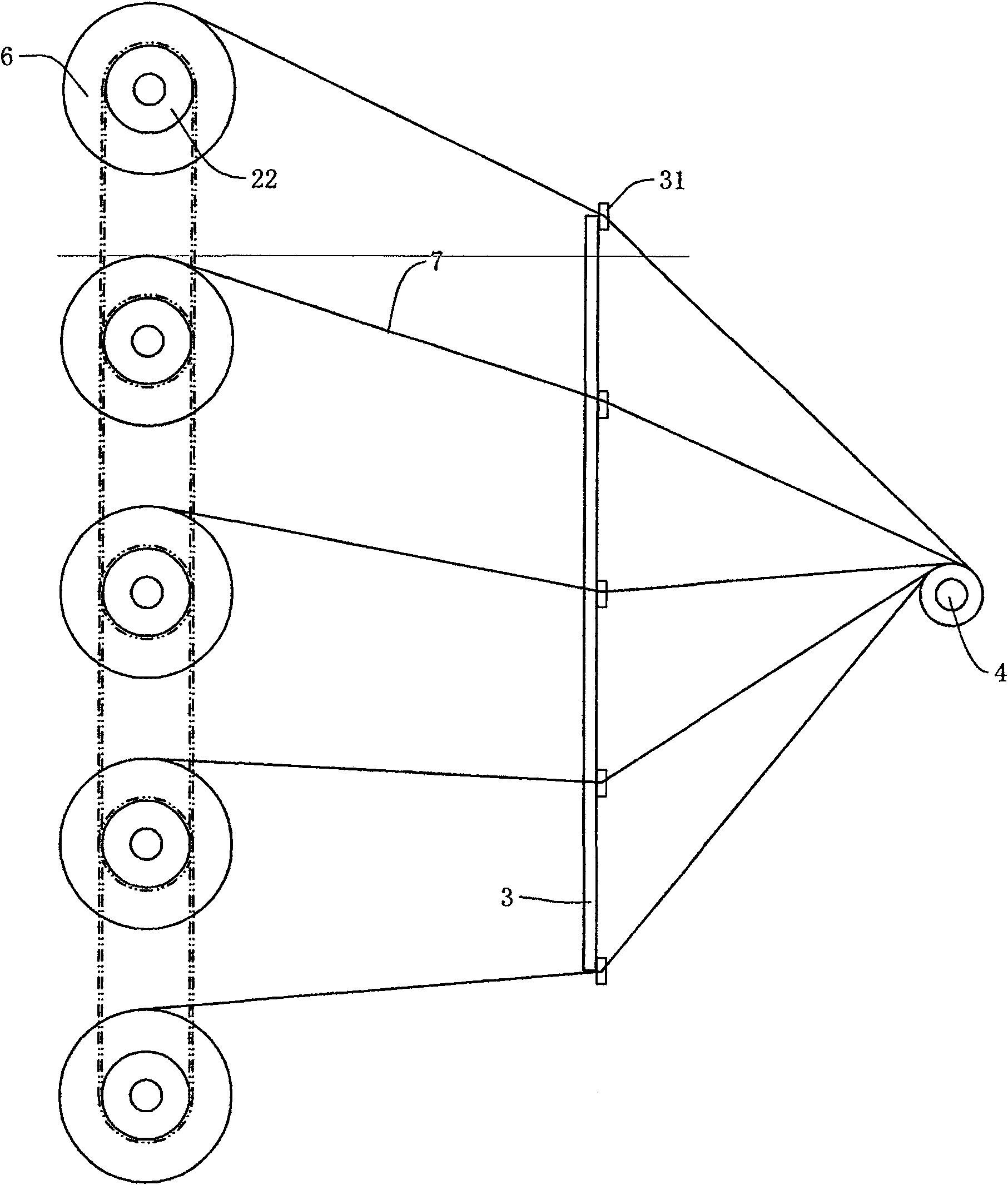

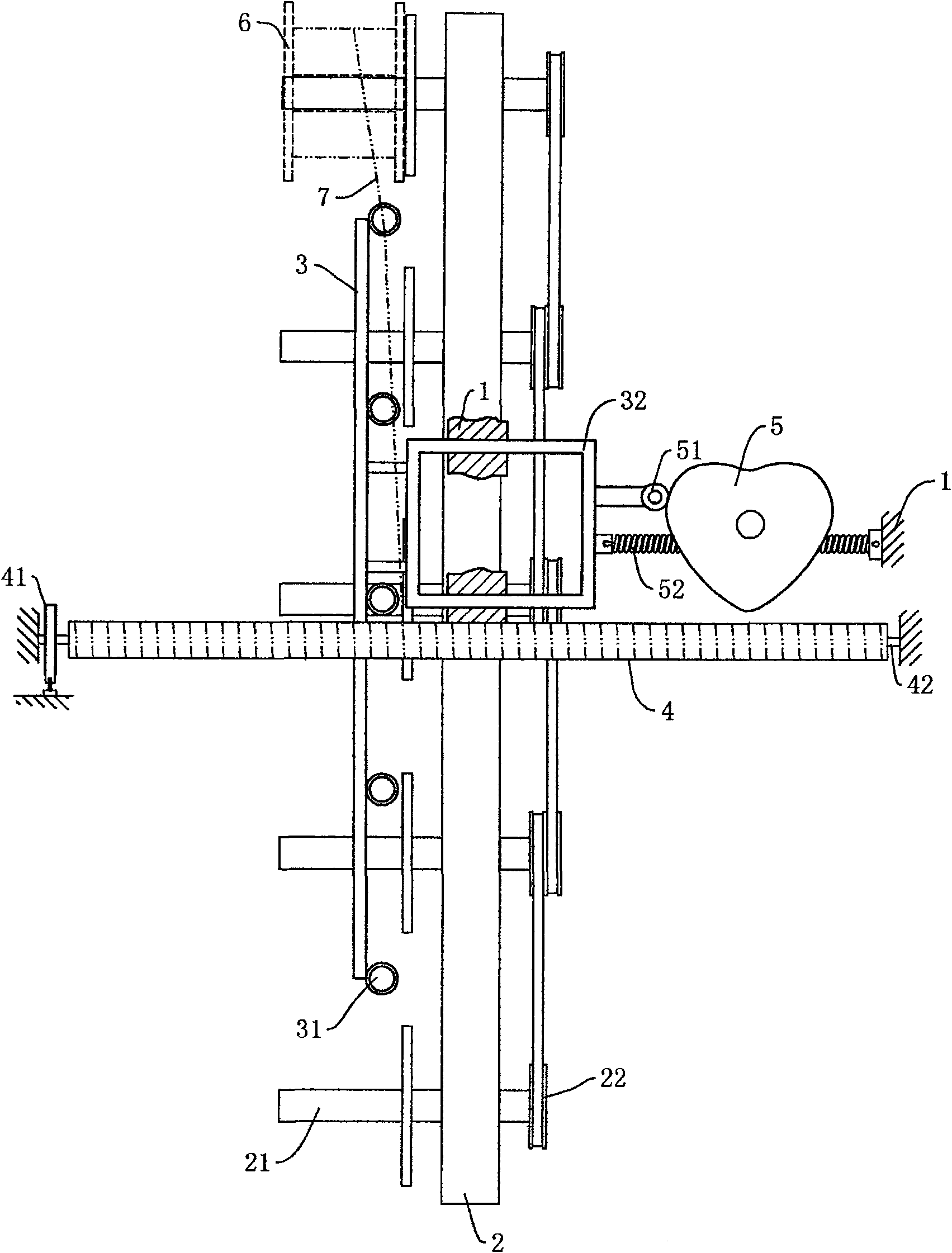

[0012] Such as figure 1 with figure 2 As shown, the mane roll unwinding machine includes a line roll frame 2 and a mane roll frame 42 provided on the body 1, and a power device such as a motor-driven gearbox etc. Lead frames 3 are arranged between them, and some wire roller seats 21 that rotate under the drive of the power device are arranged on the wire roller frame 2. For example, a belt pulley that is provided with the same rotation axis as the installed wire rollers on each wire roller seat 21 can be adopted. 22, the belt is connected between the pulleys 22 and driven by the power unit to realize the transmission; the line roller seat 21 is used to install the line roller 6 for winding the clamping line 7, and the mane roller frame 42 is used to install and wrap the clamping The mane roller 4 of wire and mane is respectively provided with the wire ring 31 corresponding to each wire roller seat 21 on the lead frame 3, and is provided with a swing device on the body, drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com