Stainless steel surface flexible wire processing technique

A treatment process, stainless steel technology, applied in the field of stainless steel surface soft silk treatment process, can solve the problem of electroplating layer falling off, affecting the service life of stainless steel products, and the surface is easy to hide dirt and evil people and practices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

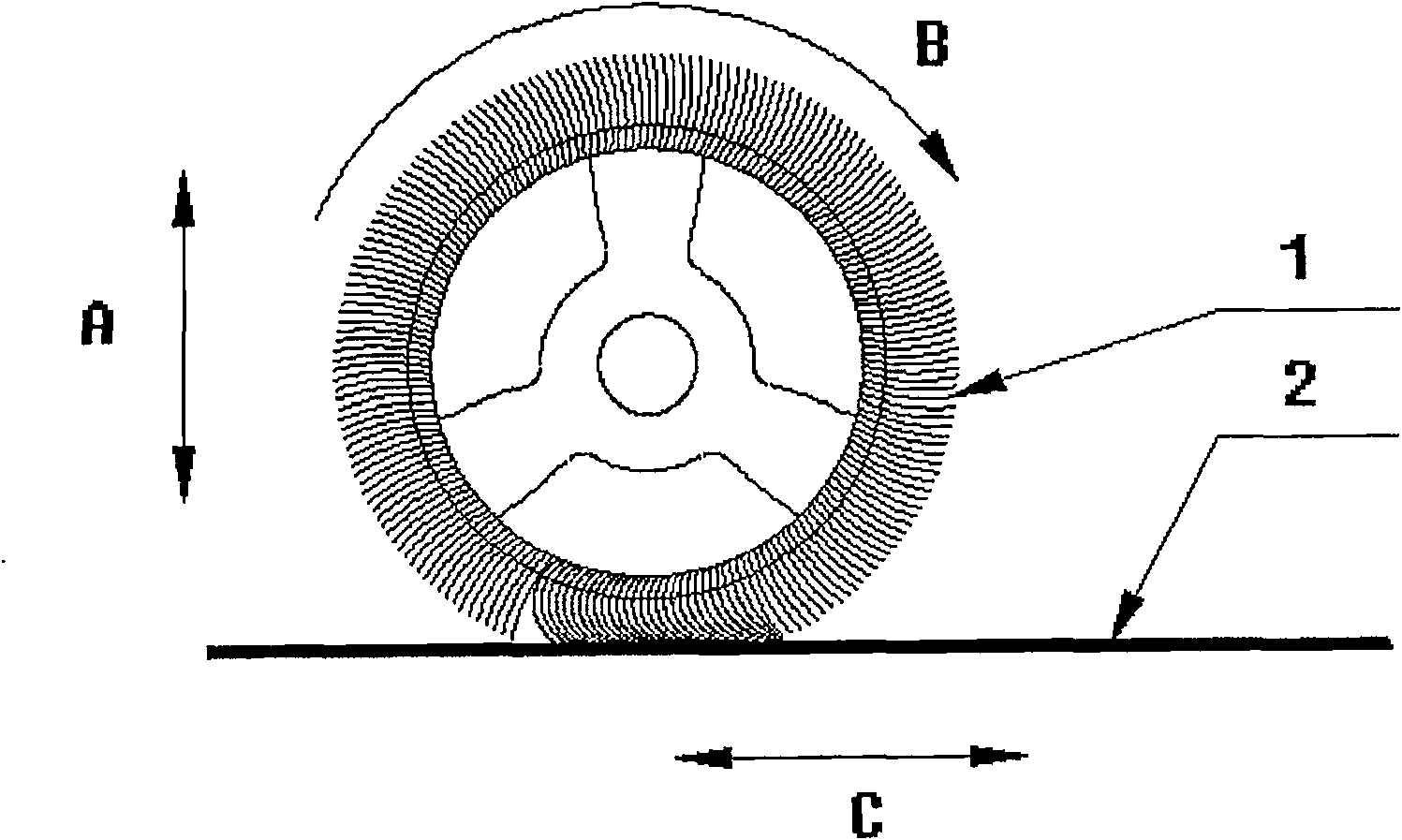

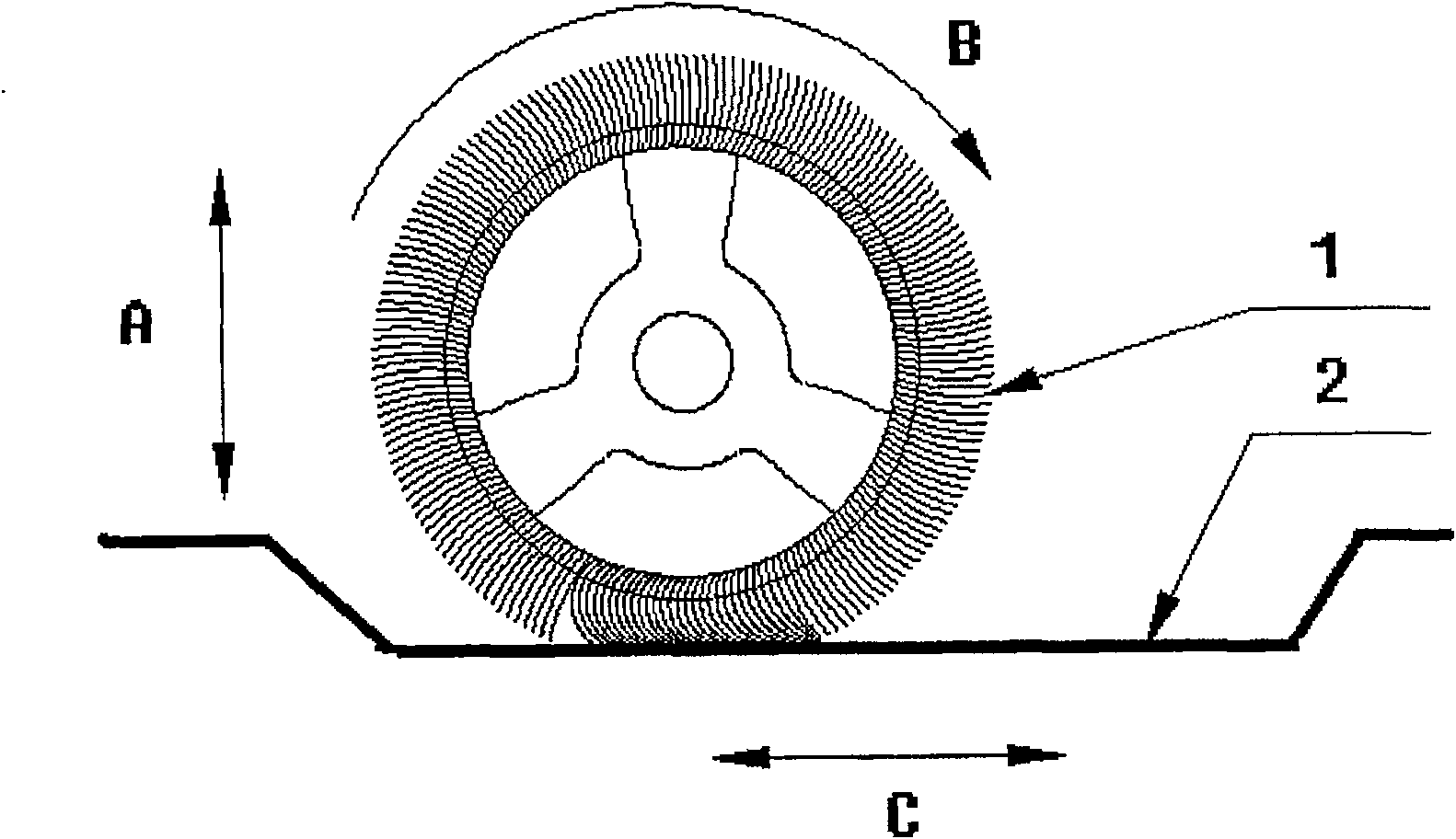

[0017] as attached figure 1 And attached figure 2 As shown, the nylon in the sanding nylon wheel 1 must first be soaked in liquid wax for 10 to 12 hours, preferably 12 hours, and then installed on a CNC polishing machine (not shown in the figure), driven by a motor to move along the figure at high speed. In the B direction, the sanding nylon wheel can move up and down along the A in the figure. First, let the sanding nylon wheel drop until it touches the stainless steel material 2 fixed on the worktable of the CNC polishing machine and rubs against it. As for the friction The magnitude of the force is specifically determined by the depth of the silk pattern formed on the surface of the stainless steel. It is better to control the depth of the thread pattern at 5-8 μm. At this time, the nozzle of the CNC polishing machine sprays water mist on the stainless steel material to cool the stainless steel parts. The temperature of the water mist is between 10 ° C and 22 ° C, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com