Patents

Literature

41results about How to "Adjust the viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unleaded solder paste and preparation method thereof

InactiveCN101934437AHigh expansion rateAdjust the viscosityWelding/cutting media/materialsSoldering mediaOrganic acidOrganic solvent

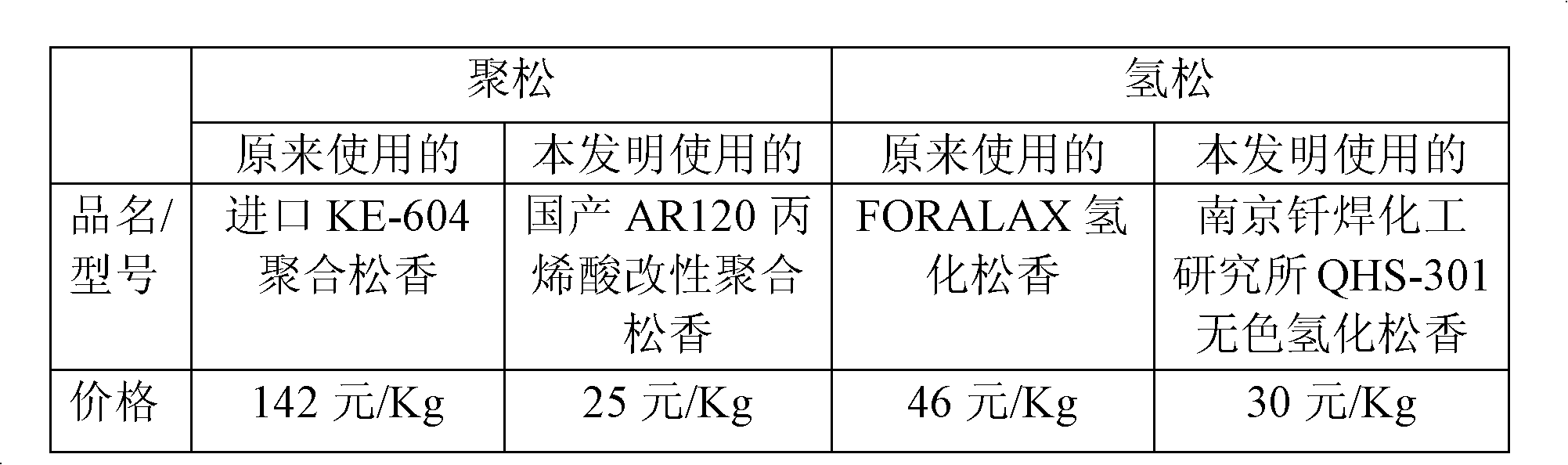

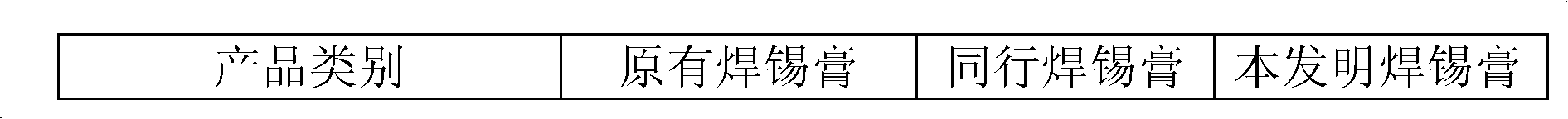

The invention relates to an unleaded solder paste and a preparation method thereof. The unleaded solder paste comprises the following raw materials in percentage by weight: 20-35% of polymerized rosin, 10-25% of hydrogenated rosin, 3-8% of modified hydrogenated castor oil, 5-15% of organic acid active agent, 4-15% of surfactant, 5-10% of softening agent, 0.2-2% of accelerating agent, 0.2-2% of antioxidant, 0.01-0.02% of halogen-containing active agent and the balance organic solvent. The unleaded solder paste can be prepared by the steps of weighting the above raw materials, stirring and vacuumizing. The unleaded solder paste in the invention adopts domestic rosin, thus greatly lowering the cost; the ratio of the organic acid is regulated, thus improving the expansion ratio of the solder paste and having good printing property; and epoxidized soybean oil is adopted as the softening agent to regulate the viscosity of the solder paste, thus increasing the storage life of the solder paste.

Owner:常州市亚太微电子材料有限公司

Exposed wall elastic anti-crack putty

This invention is related to a kind of elastic crack-resistant putty exterior walls composed by mixing base of 20-30% part, filler of 60-70% part and assistant of 8-20% part by weight. The said base contains flexible acrylic acid emulsion of 12-25% part and EVA emulsion of 5-10% part by weight. The said filler contains heavy calcium of 25-30% part, 25-30% cement and silica flour of 10-20 part by weight. The said assistant contains the following componentsby weight: dioctyl phthalate of 1-3% part, defoaming agent of 1-1.5% part, thickening agent of 2-5% part, emulsive filmogen of 3-5% part, hydroxypropyl methylcellulose of 2.5-3.0% part, woody fiber of 2-5% part, polypropylene fiber of 3-5% part, and mildew preventive of 0.5-1% part. The said putty can be used as the exterior wall coatings of both regular buildings and buildings with higher crack-resistant requirements and its dynamic crack property exceeds the national standard. The said putty can adjust the viscosity of the paste and other workabilities according to different operating requirements by selecting the variety and thickness scale of the filler, adjusting the matched ratios, and also adding proper quantities of water and assistants which satisfy different constructing requirements.

Owner:南通甜港材料科技有限公司

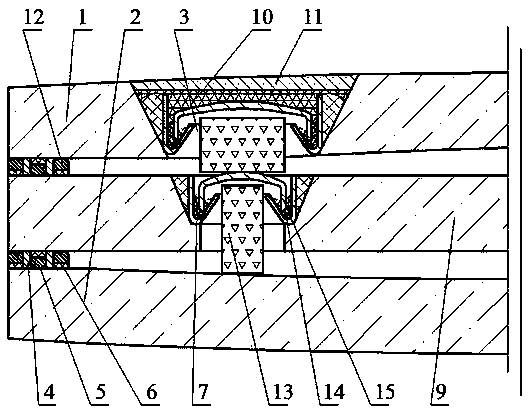

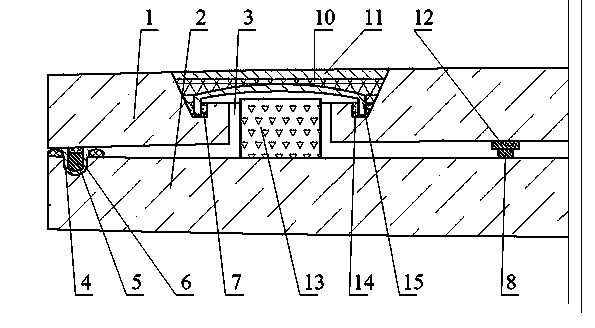

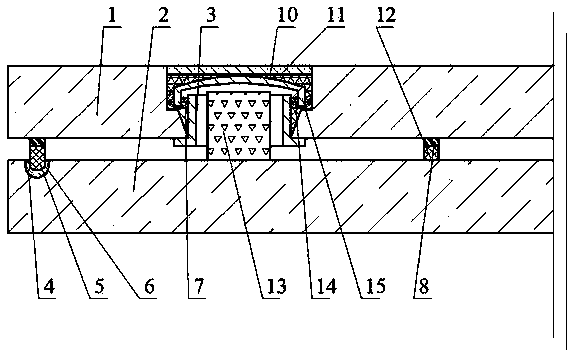

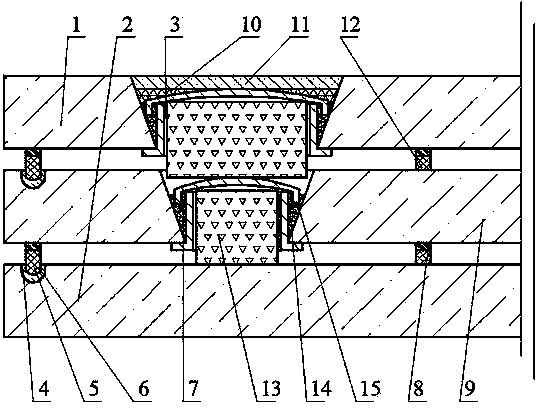

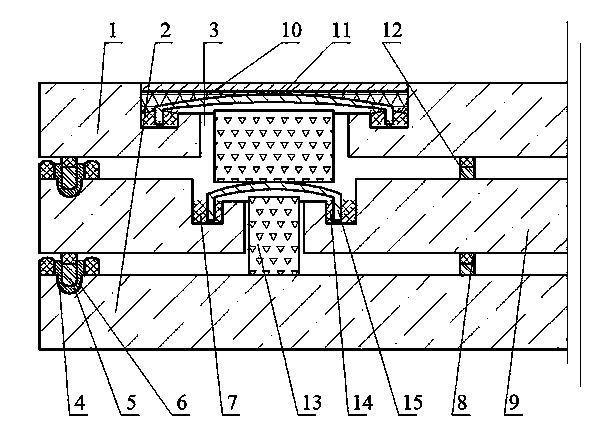

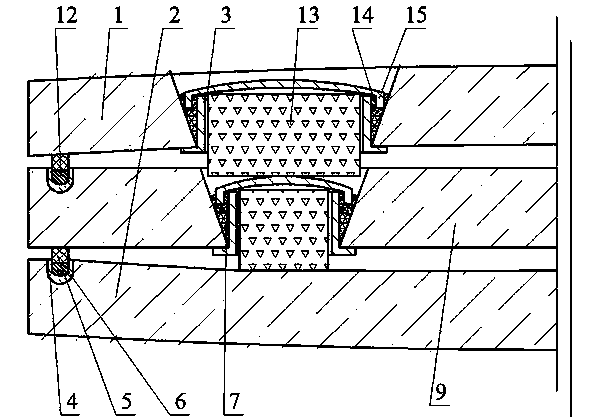

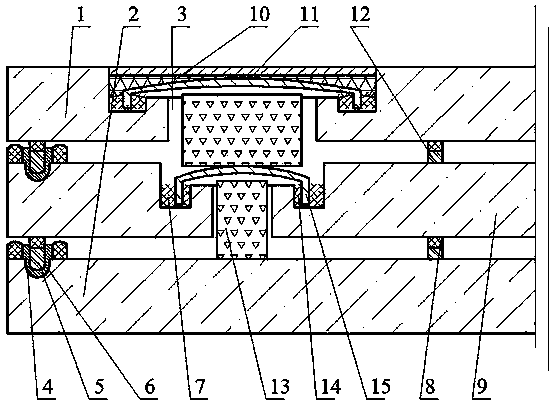

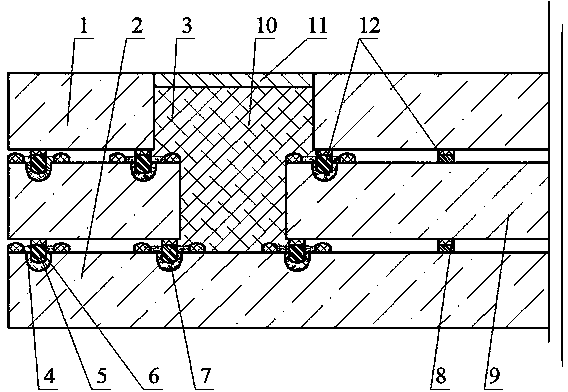

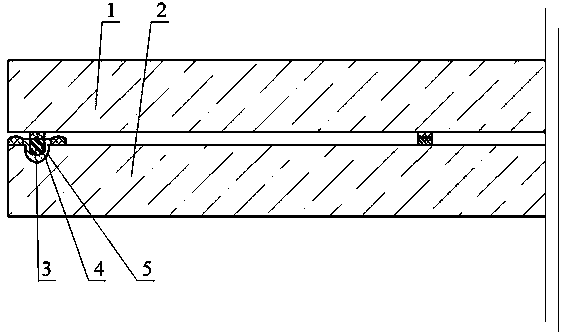

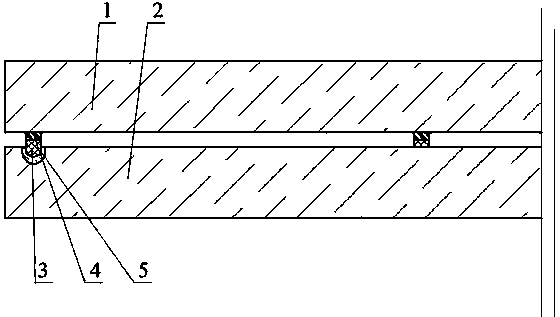

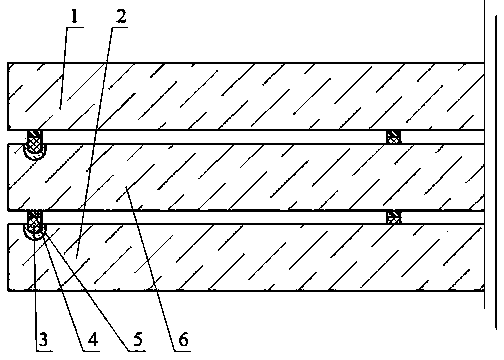

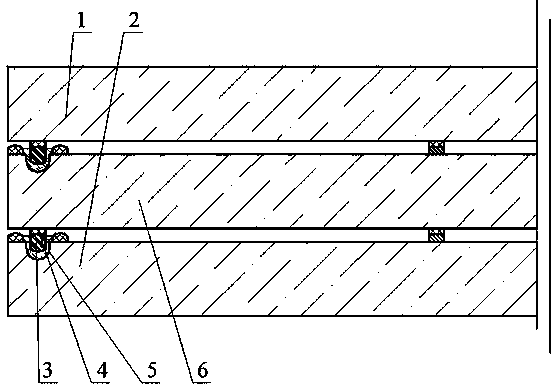

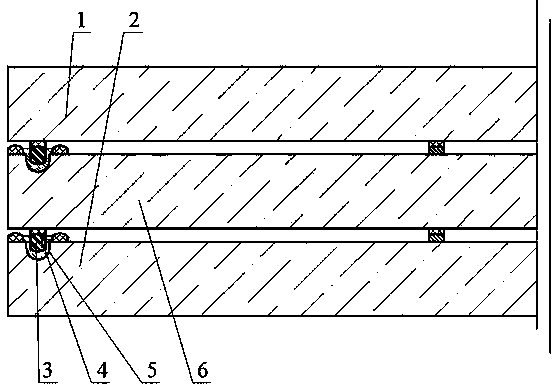

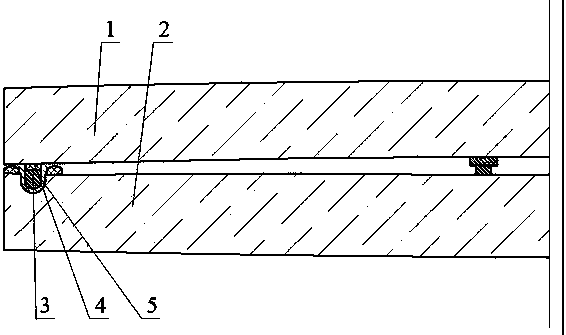

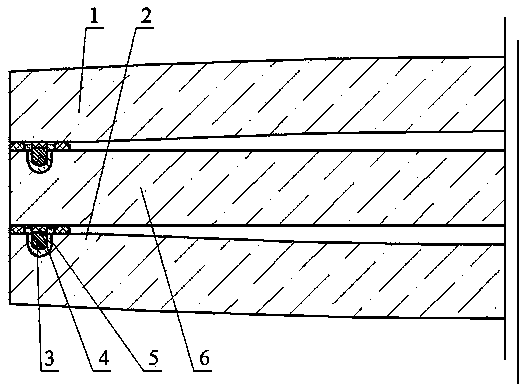

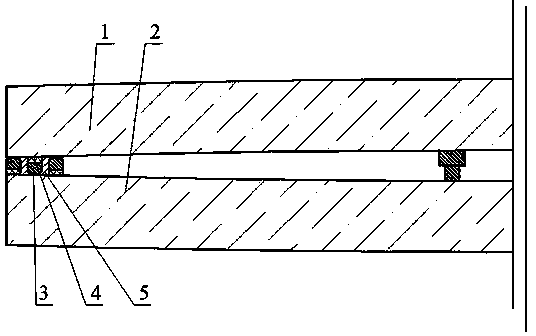

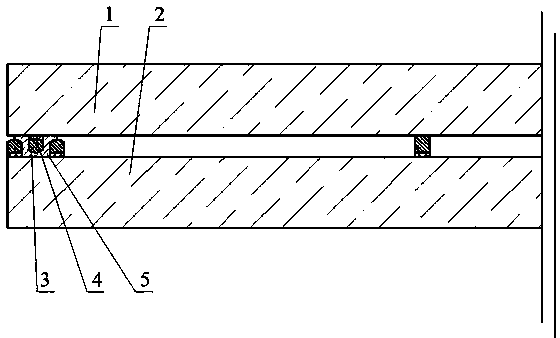

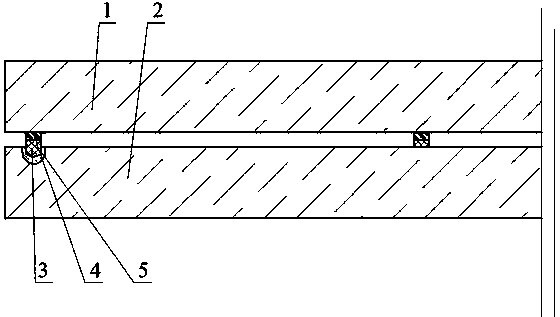

Convex tempered vacuum glass provided with getter in edge sealing of sealing strips and preparing method thereof

InactiveCN104291635ASimple sealing structureLow costGlass reforming apparatusGlass productionElastomerRoom temperature

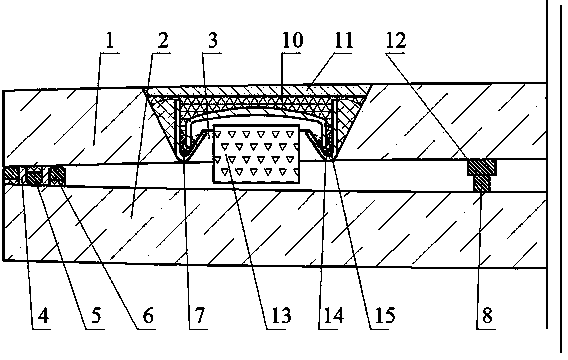

Convex tempered vacuum glass provided with a getter in edge sealing of sealing strips is disclosed. The convex tempered vacuum glass is characterized in that: upper glass and lower glass are convex tempered glass; the upper glass is provided with an extraction opening; the extraction opening is provided with a sealing cover; the getter is disposed in the extraction opening; the periphery of the upper glass and the periphery of the lower glass are provided with the sealing strips; the periphery of the upper glass and the periphery of the lower glass are welded by adoption of low-temperature glass solder at normal pressure in an edge banding furnace; the extraction opening is automatically sealed by utilization of the sealing cover and metal solder in a vacuum furnace; the getter is automatically activated in a sealing process; a closed vacuum layer is formed between the upper glass and the lower glass; the sealing strips are made of tempered glass printing ink and / or polymer; the polymer is prepared into pre-polymer firstly, and then the prepolymer is prepared onto glass or tempered glass printing ink after glass tempering; the prepolymer cures at the room temperature or high temperature to form an elastomer; the prepolymer or the elastomer can automatically adapt to changes of the height of the vacuum layer; and volatile gas in the elastomer is removed at a high temperature and under high vacuum.

Owner:戴长虹

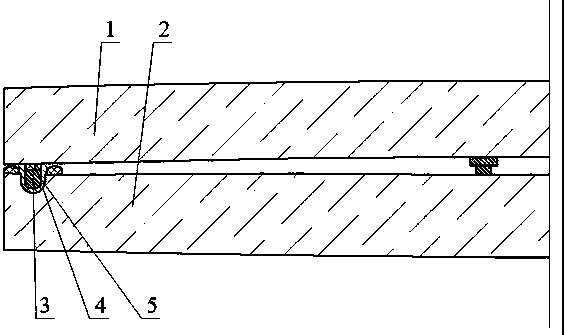

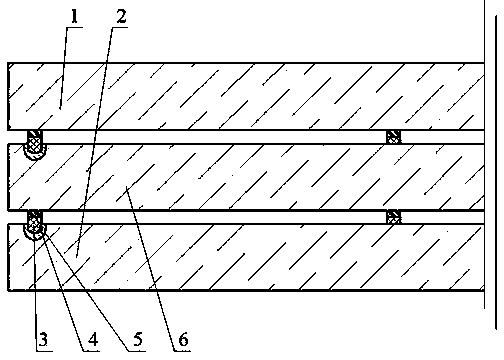

Glass-solder microwave-welded planar tempered vacuum glass edge-sealed by using bar frames

InactiveCN104291597AReduce stressReduce the breakage rate of glassGlass reforming apparatusGlass productionElastomerMicrowave

The invention relates to glass-solder microwave-welded planar tempered vacuum glass edge-sealed by using bar frames. The glass is characterized in that upper glass and lower glass are common tempered glass or plated tempered glass. Edge-sealing bar frames are provided at the peripheries of the upper glass and lower glass. The peripheries of the upper and lower glass are welded together with microwaves by using a glass solder. A sealed vacuum layer is formed between the upper glass and lower glass. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapt to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass productions of high-performance and low-cost tempered vacuum glass can be realized.

Owner:戴长虹

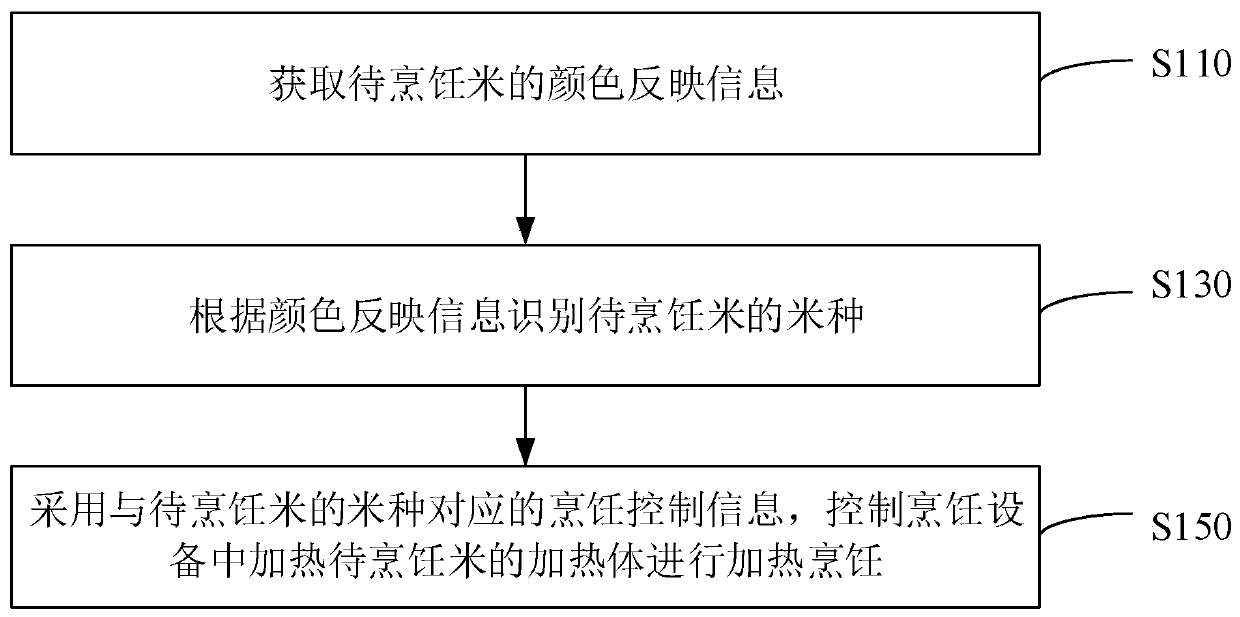

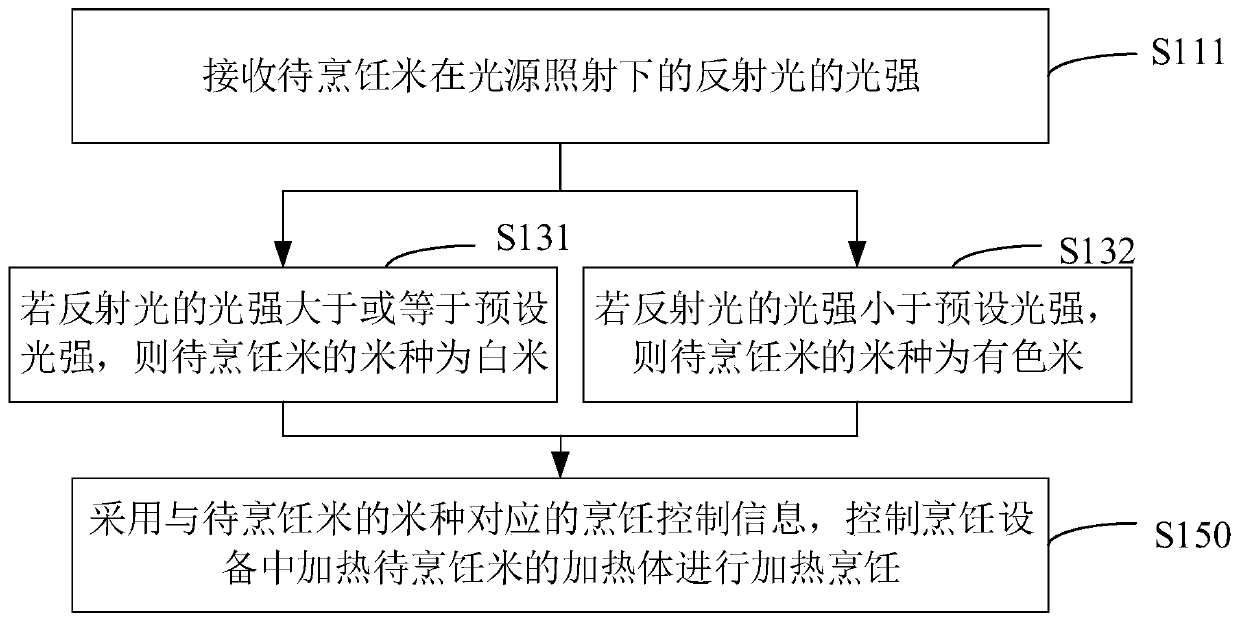

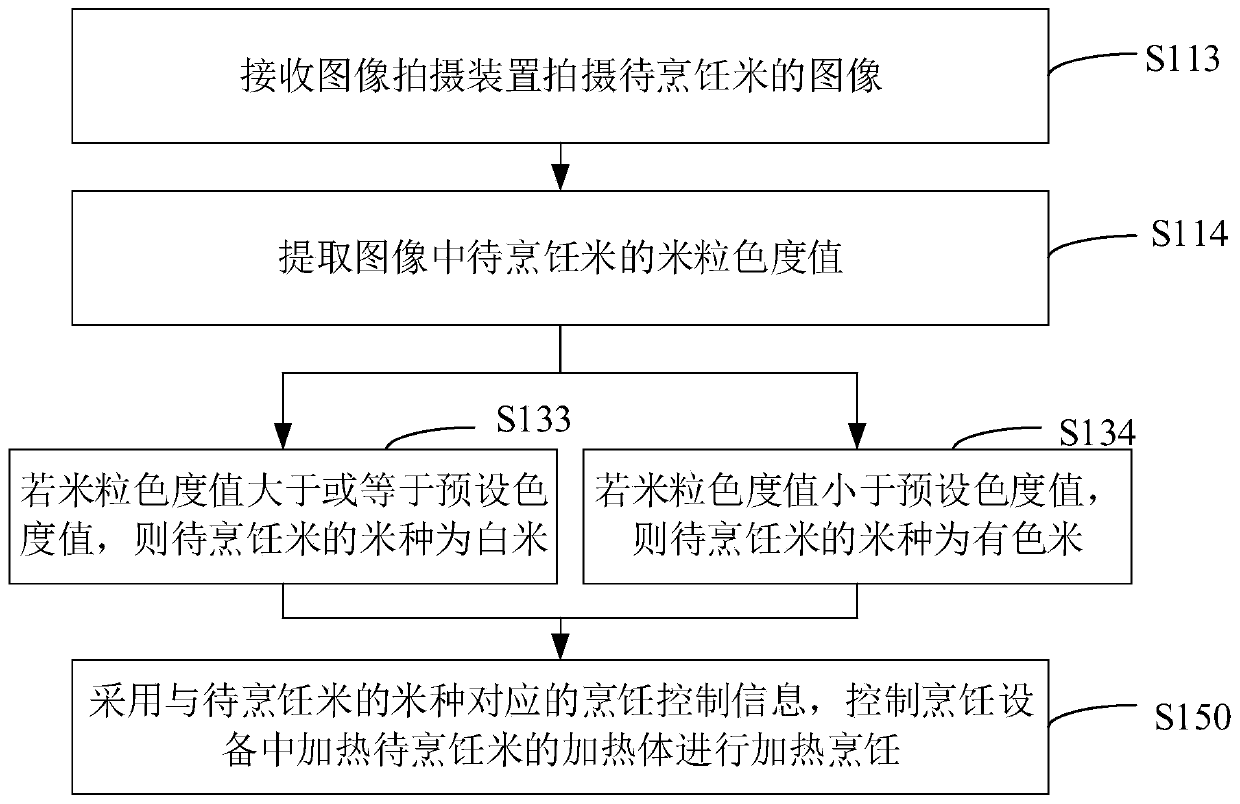

Classified cooking control method, control device, cooking device, terminal and system

InactiveCN109998364AImprove cooking performanceImprove cooking resultsTime-controlled ignitorsCooking vessel constructionsControl equipmentEngineering

The invention relates to a classified cooking control method, a control device, a cooking device, a terminal and a system. The classified cooking control method comprises the following steps: acquiring color reflecting information of to-be-cooked rice; recognizing the type of the to-be-cooked rice according to the color reflecting information; and by adopting cooking control information corresponding to the type of the to-be-cooked rice, controlling a heating body for heating the to-be-cooked rice in the cooking device to carry out heating cooking. With the technical scheme, the classified cooking control is realized, the hardness and viscosity of the different varieties of cooked rice can be adjusted with pertinence, and thus the cooking performance of the cooking device is improved.

Owner:GREE ELECTRIC APPLIANCES INC

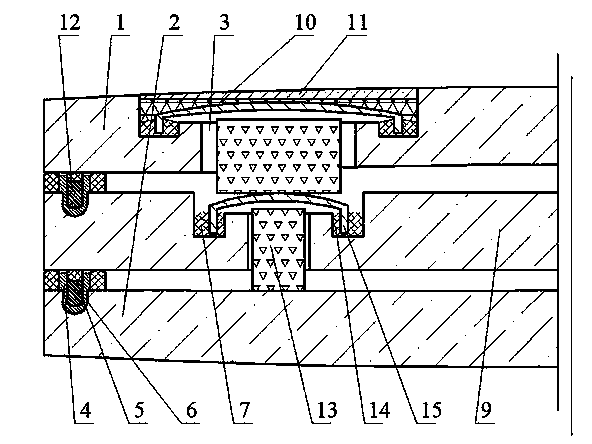

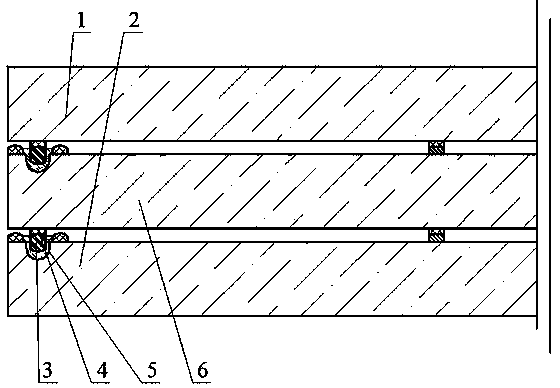

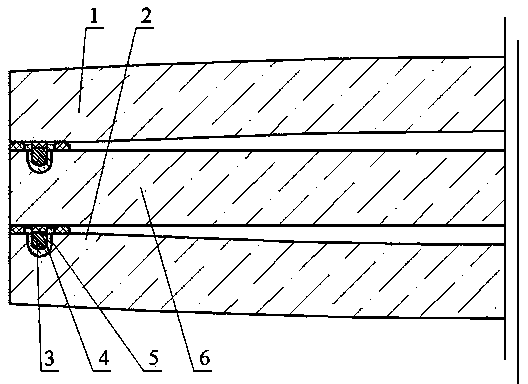

Convex toughened vacuum glass provided with getter with edges being sealed by sealing strips and sealing grooves and manufacturing method thereof

InactiveCN104291628AGuaranteed suction capacityLow costGlass reforming apparatusGlass productionElastomerRoom temperature

The invention discloses convex toughened vacuum glass provided with a getter with edges being sealed by sealing strips and sealing grooves. The convex toughened vacuum glass is characterized in that upper glass and lower glass are convex toughened glass; the upper glass is provided with an extraction opening; a sealing cover is arranged on the extraction opening; the getter is put into the extraction opening; the upper glass is provided with the sealing strips; the lower glass is provided with the sealing strips and the sealing grooves; the upper glass and the lower glass are welded together in an edge-sealing furnace under a normal pressure by using a glass solder; the extraction opening is automatically enclosed in a vacuum furnace by using the sealing cover and a metal solder; the getter is automatically activated in an edge-sealing process; an enclosed vacuum layer is formed between the upper glass and the lower glass; the sealing strips are made of toughened glass ink or / and a high polymer; the high polymer is prepared into a prepolymer firstly; after the glass is toughened, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts own contained volatile gas at a high temperature and in vacuum.

Owner:戴长虹

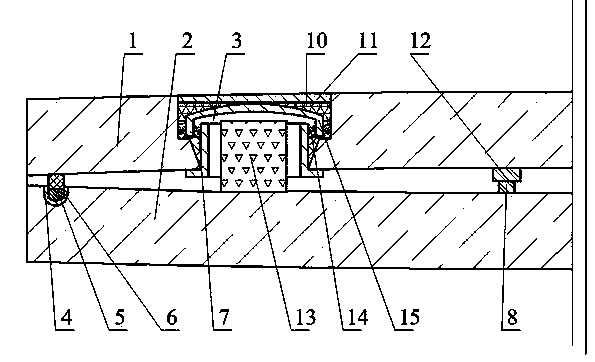

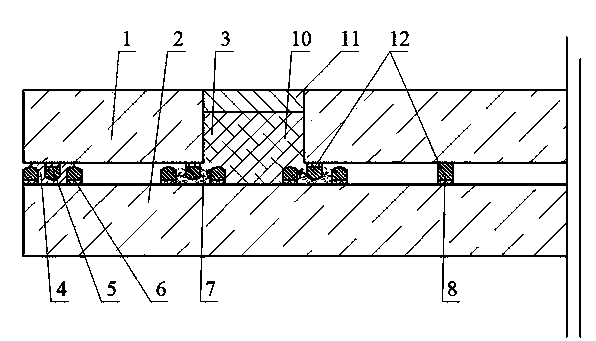

Microwave-welded flat tempered vacuum glass edge-sealed with sealing groove and having getter

InactiveCN104291647AGuaranteed suction capacitySimple sealing structureGlass reforming apparatusGlass productionElastomerMicrowave oven

A microwave-welded flat tempered vacuum glass edge-sealed with sealing grooves and having a getter is characterized in that an upper glass and a lower glass are flat tempered glasses. A vacuumizing hole is arranged in the upper glass and a sealing cover is arranged on the vacuumizing hole. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with the sealing groove. The upper glass and the lower glass are welded to each other in a microwave oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer, with a supporting object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and the supporting object are composed of tempered glass printing ink and a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

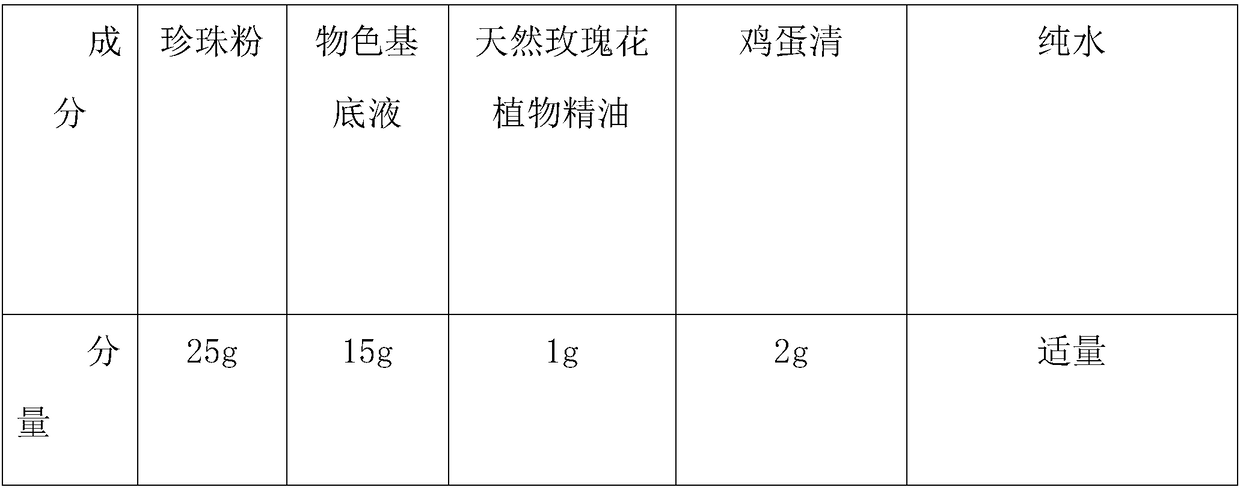

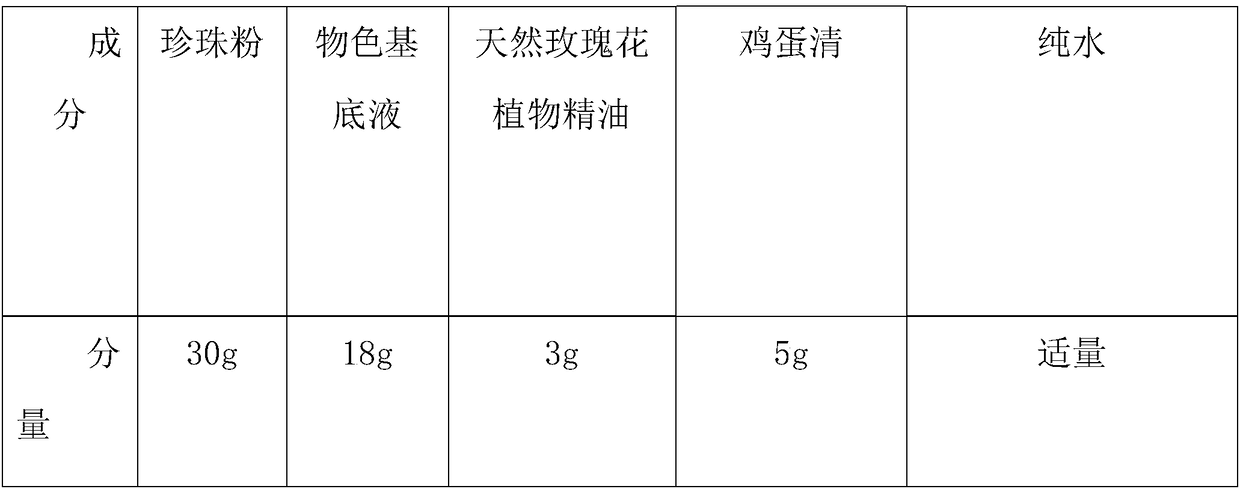

Liquid foundation capable of whitening skin and preventing allergy, and preparation method thereof

InactiveCN108904427AStop cloggingPromote absorptionCosmetic preparationsBody powdersAdditive ingredientAllergy

The invention discloses a liquid foundation capable of whitening skin and preventing allergy, and a preparation method thereof. The liquid foundation capable of whitening skin and preventing allergy comprises 25 to 30g of pearl powder, 15 to 18g of a colorless foundation liquid, 2 to 8g of a cerise lip dyeing aqueous solution, 1 to 3g of a natural rose flower plant essential oil, 2 to 5g of egg white, and an appropriate amount of purified water. The beneficial effects are that: the liquid foundation is prepared from nanometer pearl powder, rose essence extracted from rose flower leaves, and amixture of the cerise lip dyeing aqueous solution and egg white at a unique mixing ratio, so that pore blocking and pox problems of sensitive skin caused by high efficiency foundation liquid and contained mineral oil are solved, the liquid foundation is capable of tightening skin, controlling grease secretion, minimizing pores, tendering skin, delaying skin aging, cleaning and whitening skin, removing pox and acne, and shielding the sunlight, is used for skin nourishing; the nutrients can be absorbed easily; the consistency and the color can be adjusted based on personal prefer; and the liquidfoundation is suitable for more people.

Owner:佛山市欧若拉生物科技有限公司

Metal solder and microwave-welded convex toughened vacuum glass with edges being sealed by groove

The invention discloses metal solder and microwave-welded convex toughened vacuum glass with edges being sealed by groove. The convex toughened vacuum glass is characterized in that upper glass and lower glass are convex ordinary toughened glass or coated toughened glass; the welded periphery of the upper glass is provided with an edge-sealing strip border; the welded periphery of the lower glass is provided with an edge-sealing groove; the peripheries of the upper glass and the lower glass are welded together through a metal solder by using microwaves; an enclosed vacuum layer is formed between the upper glass and the lower glass; the edge-sealing strip border is made of toughened glass ink and / or a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of a method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

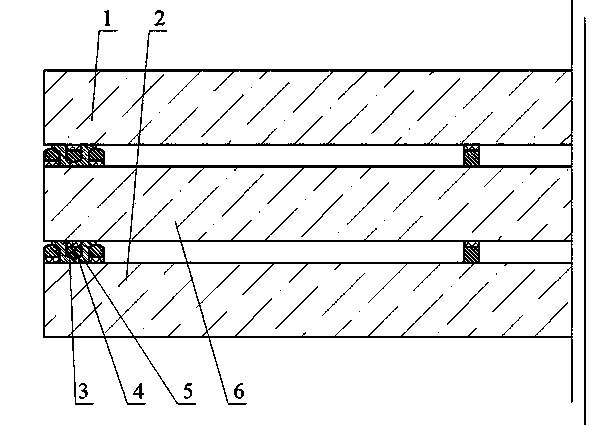

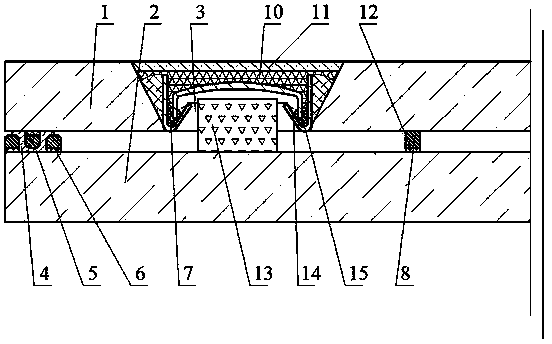

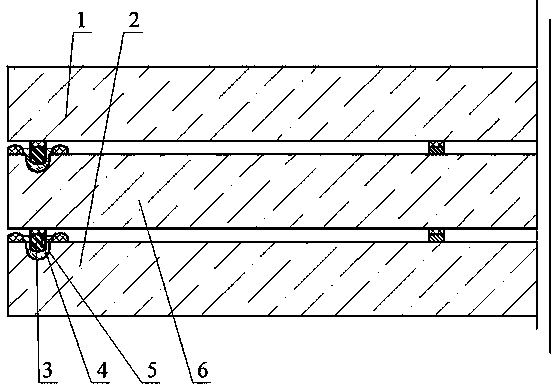

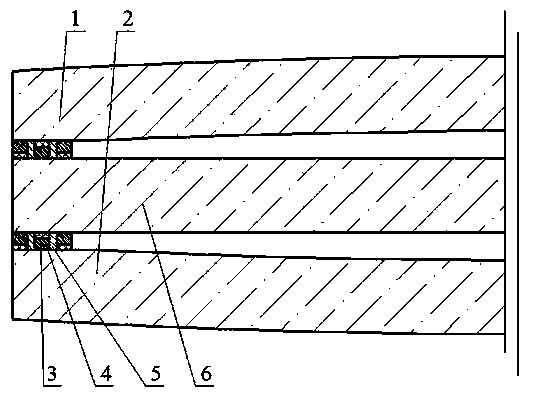

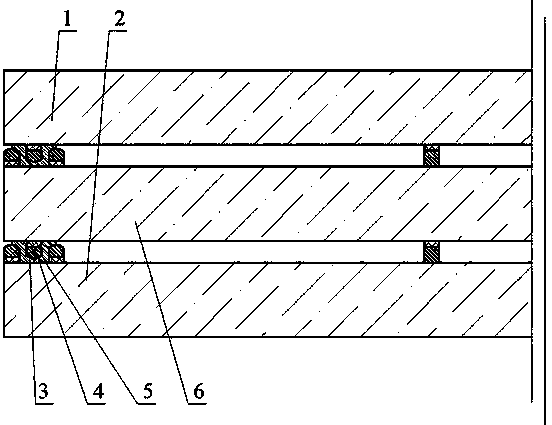

Flat tempered vacuum glass edge-sealed with sealing bars and sealing grooves and having getter and manufacturing method thereof

InactiveCN104291646AGuaranteed suction capacityLow costGlass reforming apparatusGlass productionElastomerRoom temperature

A flat tempered vacuum glass edge-sealed with sealing bars and sealing grooves and having a getter is characterized in that an upper glass and a lower glass are flat tempered glasses. A vacuumizing hole is formed in the upper glass and is provided with a seal cover. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with a sealing bar and a sealing groove. The upper glass and the lower glass are welded to each other in an edge-sealing oven at a normal pressure through a glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer, with a supporting object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and / or the supporting object are composed of tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

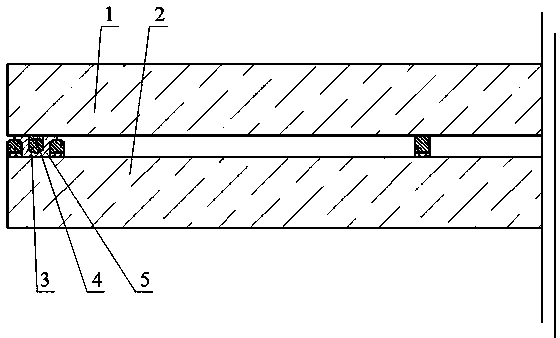

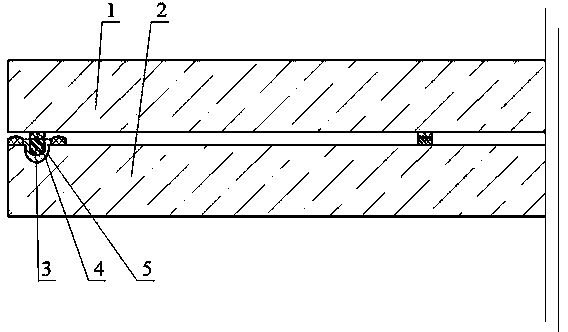

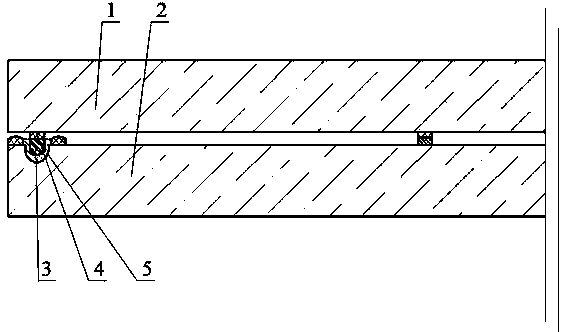

Metal-solder-welded planar toughened vacuum glass with edges being sealed by strip borders

The invention discloses metal-solder-welded planar toughened vacuum glass with edges being sealed by strip borders. The metal-solder-welded planar toughened vacuum glass is characterized in that upper glass and lower glass are planar ordinary toughened glass or coated toughened steel; the peripheries of the welding surfaces of the upper glass and the lower glass are provided with edge-sealing strip borders; the peripheries of the upper glass and the lower glass are welded together through a metal solder; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip borders and the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of the method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

Microwave-welded convex tempered vacuum glass edge-sealed with sealing groove and having getter

InactiveCN104291656AGuaranteed suction capacitySimple sealing structureGlass reforming apparatusGlass productionElastomerMicrowave oven

A microwave-welded convex tempered vacuum glass edge-sealed with sealing grooves and having a getter is characterized in that an upper glass and a lower glass are convex tempered glasses. A vacuumizing hole is arranged in the upper glass and a sealing cover is arranged on the vacuumizing hole. The getter is arranged in the vacuumizing hole. The upper glass is provided with a sealing bar and the lower glass is provided with the sealing groove. Peripheries of the upper glass and the lower glass are welded to each other in a microwave oven at a normal pressure through a glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through the seal cover and a metal solder. The getter is automatically activated during the sealing process. A vacuum layer is formed between the upper glass and the lower glass. The edge-sealing bar is manufactured from tempered glass printing ink and a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

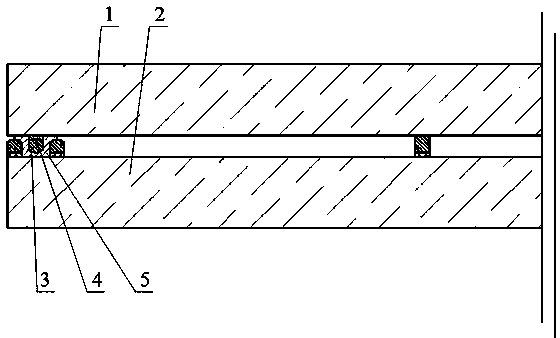

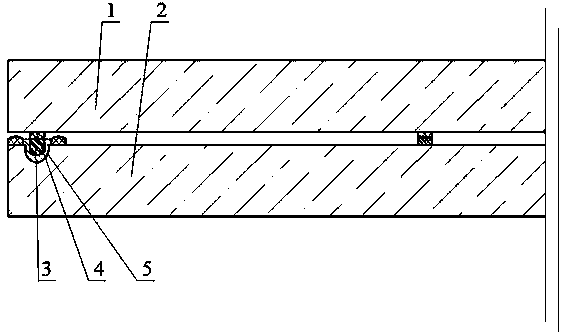

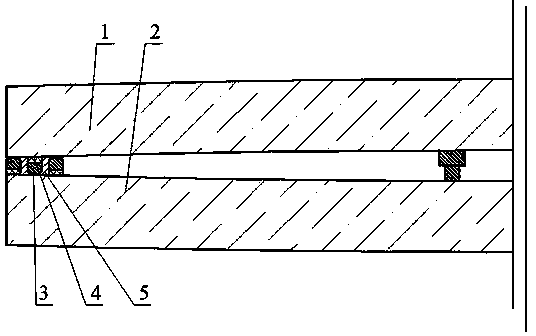

Planar tempered vacuum glass edge-sealed by using sealing strips and with getter, and preparation method thereof

InactiveCN104291604ASimple sealing structureLow costGlass reforming apparatusGlass productionElastomerRoom temperature

The invention relates to planar tempered vacuum glass which is edge-sealed by using sealing strips and which has a getter. The glass is characterized in that upper glass and lower glass are planar tempered glass. An air-exhaust port is provided on the upper glass. A sealing cap is provided on the air-exhaust port. The getter is placed in the air-exhaust port. Sealing strips are provided at the peripheries of the upper glass and the lower glass. The peripheries of the upper and lower glass are welded together by using a glass solder under normal pressure in an edge-sealing furnace. The air-exhaust port is automatically sealed in a vacuum furnace with the sealing cap and with a metal solder. The getter is automatically activated during the sealing process. A vacuum layer is formed between the upper glass and the lower glass. A supporter is provided in the vacuum layer. The sealing strips and / or the supporter is composed of tempered glass ink and / or a high-polymer. The high-polymer is first prepared into a pre-polymer. After the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapted to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum.

Owner:戴长虹

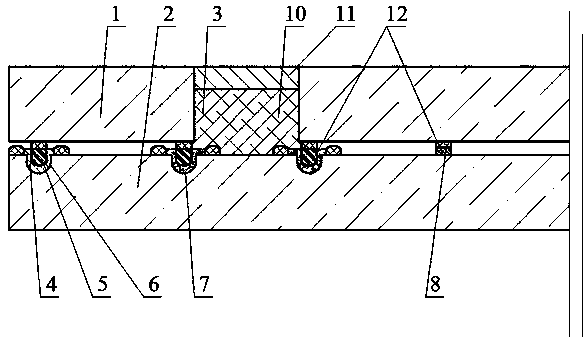

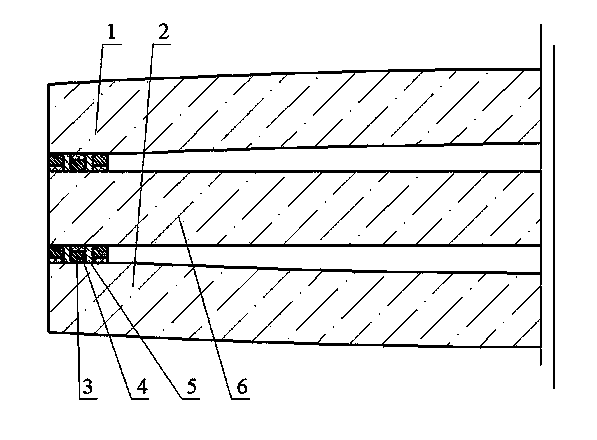

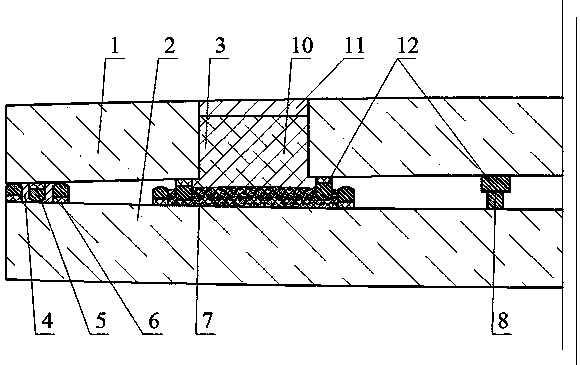

Microwave-welded planar tempered vacuum glass edge-sealed by using sealing strips and a sealing groove and provided with getter

InactiveCN104291620AGuaranteed suction capacitySimple sealing structureGlass reforming apparatusGlass productionElastomerMicrowave oven

The invention relates to microwave-welded planar tempered vacuum glass which is edge-sealed by using sealing strips and a sealing groove and which is provided with a getter. The glass is characterized in that upper glass and lower glass are planar tempered glass. An air-exhaust port is provided on the upper glass. A sealing cap is provided on the air-exhaust port. The getter is placed in the air-exhaust port. A sealing strip is provided on the upper glass, and sealing strips and a sealing groove are provided on the lower glass. The upper glass and the lower glass are welded together by using a glass solder under normal pressure in a microwave oven. The air-exhaust port is automatically sealed by using the sealing cap and with a metal solder in a vacuum furnace. The getter is automatically activated during the port-sealing process. A vacuum layer is formed between the upper glass and the lower glass. Supporters are provided in the vacuum layer. The sealing strips and the supporters are prepared by using tempered glass ink or a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapted to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum.

Owner:戴长虹

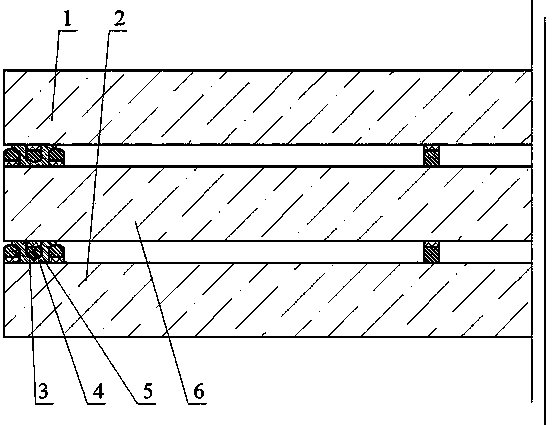

Planar tempered vacuum glass microwave-welded by using metal solder and edge-sealed by using bar frames and groove

The invention relates to a planar tempered vacuum glass which is microwave-welded by using a metal solder and which is edge-sealed by using bar frames and a groove. The glass is characterized in that upper glass and lower glass are planar tempered glass. An edge-sealing bar frame is provided on the periphery of the upper glass; an edge-sealing bar frame and an edge-sealing groove are provided on the periphery of the lower glass; the peripheries of the upper glass and the lower glass are welded together by using a metal solder, such that a sealed vacuum layer is formed. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer; when the glass is tempered, the pre-polymer is prepared on the tempered glass ink; and the pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or the elastomer can be automatically adapted to the changes of vacuum layer height. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass production of tempered vacuum glass with high performance and low cost can be realized.

Owner:戴长虹

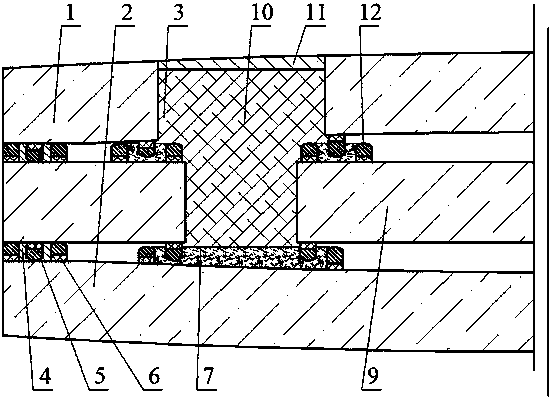

Microwave-welded planar tempered vacuum glass edge-sealed by using sealing strips and sealing grooves and provided with air-exhaust port

InactiveCN104291590AAchieving tightnessGuaranteed tightnessGlass reforming apparatusGlass productionElastomerMicrowave oven

The invention relates to microwave-welded planar tempered vacuum glass which is edge-sealed by using sealing strips and sealing grooves and which is provided with an air-exhaust port. The glass is characterized in that upper glass and lower glass are planar tempered glass. The air-exhaust is provided on the upper glass. Sealing strips are provided at the periphery of the upper glass and at the periphery of the air-exhaust port. Sealing strips and sealing grooves are provided at the periphery of the lower glass and at the place corresponding to the air-exhaust port. The peripheries of the upper glass and lower glass are welded together by using a glass solder under normal pressure in a microwave oven. The air-exhaust port is automatically sealed by using a metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. One or two layers of supporters are provided in the vacuum layer. The sealing strips and the supporters are composed of tempered glass ink or a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapt to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum.

Owner:戴长虹

Food coating for biscuits or mooncakes

InactiveCN107318929AAdjust the viscosityDelay oxidative metamorphosisBakery productsSaccharumFatty acid

The invention discloses a food coating for biscuits or mooncakes. The food coating is made from, by mass, 20-30 parts of condensed milk, 10-20 parts of white chocolate, 3-5 parts of green tea powder, 1-3 parts of soybean oil, 1-4 parts of xanthan gum, 1-2 parts of saccharose, 1-3 parts of fatty acid polyglycerol ester, 1-3 parts of isosorbide dinitrate and 1-2 parts of edible pigment. The food coating is low in production cost, safe and healthy, the raw materials are edible, the coating can coat the surfaces of most of biscuits or mooncake products, the original taste is not affected, the compact coating is formed on the surfaces of the biscuits or the mooncakes, on one hand, air can be isolated, the phenomenon that the taste is affected due to water absorption is avoided, the shelf life is prolonged, meanwhile, the food coating is bright in color and can coat the surfaces of biscuits or mooncakes to form various patterns, the appetite of people can be enhanced, and the ornamental value can be increased.

Owner:苏州稻香村食品有限公司

Planar toughened vacuum glass welded by using glass solder with edges being sealed by strip borders and groove

InactiveCN104291582AReduce stressReduce breakage rateGlass reforming apparatusGlass productionElastomerRoom temperature

The invention discloses planar toughened vacuum glass welded by using a glass solder with edges being sealed by strip borders and a groove. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar ordinary toughened glass or coated toughened glass; the periphery of the upper glass is provided with an edge-sealing strip border; the periphery of the lower glass is provided with an edge-sealing strip border and an edge-sealing groove; the peripheries of the upper glass and the lower glass are welded together through a glass solder, thereby forming an enclosed vacuum layer; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip borders and the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of the method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

Planar toughened vacuum glass welded through metal solder by means of microwaves with edges being sealed by grooves

The invention discloses planar toughened vacuum glass welded through a metal solder by means of microwaves with edges being sealed by grooves. The planar toughened vacuum glass consists of upper glass and lower glass, and is characterized in that the periphery of the upper glass is provided with an edge-sealing strip border; the periphery of the lower glass is welded with an edge-sealing groove; the peripheries of the upper glass and the lower glass are welded together through the metal solder by means of microwaves; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip border and the support objects are made by compounding toughened glass ink and / or a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature at last; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts own contained volatile gas at a high temperature and in high vacuum. Through adoption of a method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

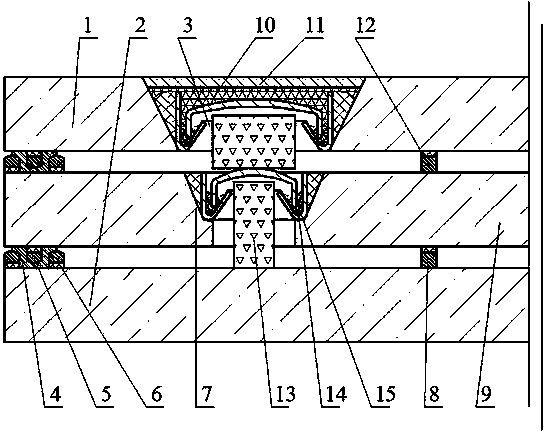

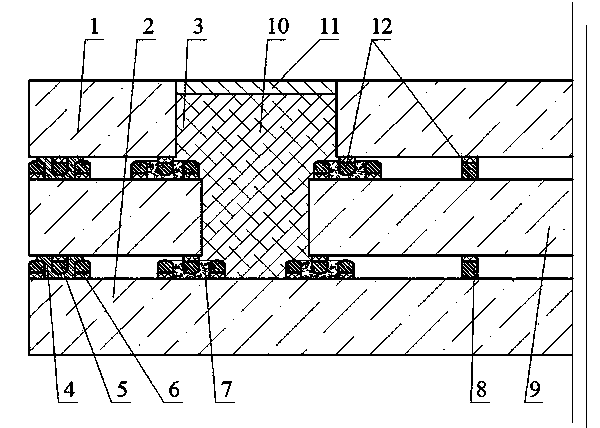

Convex tempered vacuum glass welded by using glass golder and edge-sealed by using bar frames and groove

InactiveCN104291592AHigh compressive strengthImprove flexural strengthGlass reforming apparatusGlass productionElastomerRoom temperature

The invention relates to convex tempered vacuum glass welded by using a glass solder and edge-sealed by using bar frames and a groove. The convex tempered vacuum glass has the following characteristics: upper glass and lower glass are convex common tempered glass or coated tempered glass; an edge-sealing bar frame is provided on the periphery of a welding surface of the upper glass; an edge-sealing bar frame and a sealing groove are provided on the periphery of a welding surface of the lower glass; the peripheries of the upper glass and the lower glass are welded together by using a low-temperature glass solder, such that a sealed vacuum layer is formed between the upper glass and the lower glass. The edge-sealing bar frames are prepared by using tempered glass ink and / or a high-polymer. The high-polymer is first prepared into a pre-polymer; when the glass is tempered, the pre-polymer is prepared on the tempered glass ink; and the pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or the elastomer can be automatically adapted to the changes of vacuum layer height. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass production of tempered vacuum glass with high performance and low cost can be realized.

Owner:戴长虹

Metal-solder-welded planar toughened vacuum glass with edges being sealed by strip borders and groove

The invention discloses metal-solder-welded planar toughened vacuum glass with edges being sealed by strip borders and groove. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar ordinary toughened glass or coated toughened glass; the periphery of the upper glass is provided with an edge-sealing strip border; the periphery of the lower glass is provided with an edge-sealing strip border and an edge-sealing groove; the peripheries of the upper glass and the lower glass are welded together through a metal solder, thereby forming an enclosed vacuum layer; one or two layers of support objects are arranged in the vacuum layer; the sealing strip borders and the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of a method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

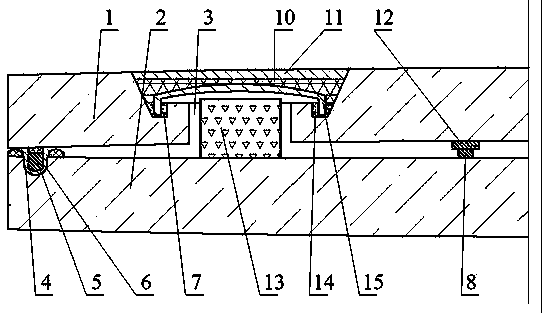

Flat tempered vacuum glass edge-sealed with sealing bar and having vacuumizing hole and manufacturing method thereof

InactiveCN104291660AExtend your lifeImprove productivityGlass reforming apparatusGlass productionElastomerRoom temperature

A flat tempered vacuum glass edge-sealed with sealing bars and having a vacuumizing hole is characterized in that an upper glass and a lower glass are flat tempered glass. A vacuumizing hole is formed in the upper glass. Peripheries of the upper glass and the vacuumizing hole are provided with the sealing bars and the periphery of the lower glass and positions corresponding to the vacuumizing hole are provided with the sealing bars. The peripheries of the upper glass and the lower glass are welded to each other in an edge-sealing oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through a metal solder. A sealed vacuum layer, with a dot-array-arranged support object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and / or the support object are composed of tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. Finally the pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Glass-solder microwave-welded planar tempered vacuum glass with edge sealed by using bar frames and groove

InactiveCN104291601AReduce stressReduce the breakage rate of glassGlass reforming apparatusGlass productionElastomerMicrowave

The invention relates to glass-solder microwave-welded planar tempered vacuum glass with the edge sealed by using bar frames and a groove. The glass is characterized in that upper glass and lower glass are planar tempered glass. An edge-sealing bar frame is provided on the periphery of the upper glass. An edge-sealing bar frame and an edge-sealing groove are provided on the periphery of the lower glass. The peripheries of the upper glass and the lower glass are welded together with a glass solder by using microwave, such that a sealed vacuum layer is formed. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the tempered glass ink. the pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapted to the changes of the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass productions of high-performance and low-cost tempered vacuum glass can be realized.

Owner:戴长虹

Convex tempered vacuum glass microwave-welded by using metal solder and edge-sealed by using bar frames and groove

The invention relates to a convex tempered vacuum glass which is microwave-welded by using a metal solder and which is edge-sealed by using bar frames and a groove. The glass is characterized in that upper glass and lower glass are convex common tempered glass or coated tempered glass. An edge-sealing bar frame is provided on the welding periphery of the upper glass; an edge-sealing bar frame and an edge-sealing groove are provided on the welding periphery of the lower glass; the peripheries of the upper glass and the lower glass are welded together by using a metal solder, such that a sealed vacuum layer is formed between the upper glass and the lower glass. The edge-sealing bar frames are prepared by using tempered glass ink and / or a high-polymer. The high-polymer is first prepared into a pre-polymer; when the glass is tempered, the pre-polymer is prepared on the tempered glass ink; and the pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or the elastomer can be automatically adapted to the changes of vacuum layer height. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass production of tempered vacuum glass with high performance and low cost can be realized.

Owner:戴长虹

A kind of Gnadma polysaccharide and its composition and preparation method

ActiveCN106432519BIncrease frequencyHigh strengthOrganic active ingredientsMetabolism disorderBiotechnologyContinuous use

Provided are a Ganoderma polysaccharide, combination thereof, and manufacturing method of same. The Ganoderma polysaccharide is a Ganoderma lingzhi polysaccharide with a potassium ligand. The polysaccharide provides the following benefits: ability to respond to a T-lymphocyte in blood, and induce accelerated and high strength multiple fission of the T-lymphocyte to generate an effector T cell; non-toxic to multiple fission of a normal cell, and toxic to multiple fission of a tumor cell; continuous use causes gradual cell death in the tumor cell, allowing an organism to restore high quality survival and continued survivability, benefiting a patient with hyperglycemia and high blood lipids.

Owner:SHENZHEN OLIMEI BIOLOGICAL ENG CO LTD

Convex toughened vacuum glass welded through metal solder by means of microwaves with edges being sealed by strip borders

The invention discloses convex toughened vacuum glass welded through a metal solder by means of microwaves with edges being sealed by strip borders. The convex toughened vacuum glass is characterized in that upper glass and lower glass are convex ordinary toughened glass or coated toughened glass; the welding peripheries of the upper glass and the lower glass are provided the edge-sealing strip borders; the peripheries of the upper glass and the lower glass are welded together through the metal solder by means of microwaves; an enclosed vacuum layer is formed between the upper glass and the lower glass; the edge-sealing strip borders are made of toughened glass ink and / or a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts own contained volatile gas at a high temperature and in high vacuum. Through adoption of a method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

Convex tempered vacuum glass welded by glass solder and edge-sealed through bar frame

InactiveCN104291641AHigh compressive strengthImprove flexural strengthGlass reforming apparatusGlass productionElastomerRoom temperature

A convex tempered vacuum glass welded by a glass solder and edge-sealed through a bar frame is characterized in that upper glass and lower glass are convex glass and are common tempered glass or film-coated tempered glasses. The peripheries of welding surfaces of the upper glass and the lower glass are provided with edge-sealed bar frames and the peripheries of the upper glass and the lower glass are welded to each other through a low-temperature glass solder. A sealed vacuum layer is formed between the upper glass and the lower glass. The edge-sealed bar frames are manufactured from tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree. The method is easy to be mechanized and automate and can be used for manufacturing the tempered vacuum glass with high performance and low cost in large scale.

Owner:戴长虹

Planar toughened vacuum glass welded by using metal solder by means of microwave welding with edges being sealed by strip borders

The invention discloses planar toughened vacuum glass welded by using a metal solder by means of microwave welding with edges being sealed by strip borders. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar ordinary toughened glass or coated toughened glass; the peripheries of the upper glass and the lower glass provided with edge-sealing strip borders; the peripheries of the upper glass and the lower glass are welded together through the glass solder by means of microwave welding; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip borders and the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of the method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

Convex tempered vacuum glass edge-sealed with sealing bars and having vacuumizing hole and manufacturing method thereof

InactiveCN104291653AEasy edge banding and sealingHigh bonding strengthGlass reforming apparatusGlass productionVacuum furnacePrinting ink

A convex tempered vacuum glass edge-sealed with sealing bars and sealing groove and having a vacuumizing hole is characterized in that an upper glass and a lower glass are convex tempered glass. A vacuumizing hole is formed in the upper glass. Peripheries of the upper glass and the vacuumizing hole are provided with the sealing bars and the periphery of the lower glass and positions corresponding to the vacuumizing hole are provided with the sealing bars. The peripheries of the upper glass and the lower glass are welded to each other in an edge-sealing oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through a metal solder. A sealed vacuum layer is formed between the upper glass and the lower glass. The edge-sealing bar is manufactured from tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. The pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Flat tempered vacuum glass welded by metal solder and edge-sealed with groove

A flat tempered vacuum glass welded by a glass solder and edge-sealed through a groove is composed of an upper glass and a lower glass and is characterized in that a periphery of the upper glass is provided with an edge-sealing bar frame and the periphery of the lower glass is provided with an edge-sealing groove. The peripheries of the upper glass and the lower glass are welded to each other through the metal solder. A sealed vacuum layer, with a supporting object therein, is formed between the upper glass and the lower glass, wherein the supporting object includes one layer or two layers. The edge-sealing bar frame and the supporting object are manufactured from tempered glass printing ink and a high polymer in a composite manner. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. Finally the pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree. The method is easy to mechanize and automate and can be used for manufacturing the tempered vacuum glass with high performance and low cost in large scale.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com