Electro-hydraulic servo vibration table resonance suppressing method

An electro-hydraulic servo and resonance suppression technology, which is applied in the field of mechanical engineering, can solve problems such as no one has studied, the power spectrum reproduction control error exceeds the limit, and the bandwidth of the electro-hydraulic servo vibration table is limited, so as to improve the accuracy and expand the bandwidth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

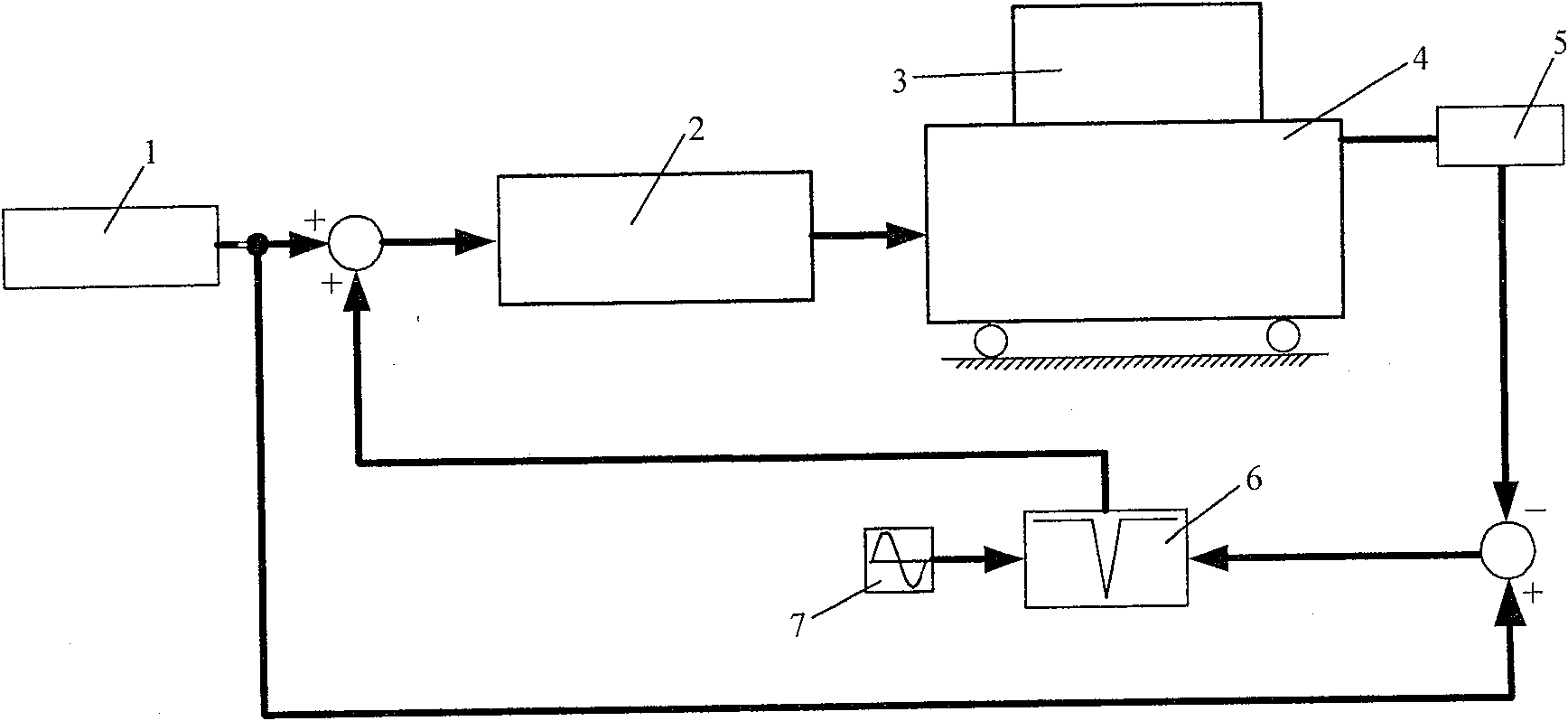

[0018] The principle diagram of adaptive suppression of the resonance peak of the electro-hydraulic servo vibration table is as follows: figure 1 As shown, the specific steps are:

[0019] 1 Use the signal generator 1 to generate a random wave signal to measure the frequency characteristic curve of the electro-hydraulic servo vibration table, and the position of its resonance peak can be known from its frequency characteristic curve.

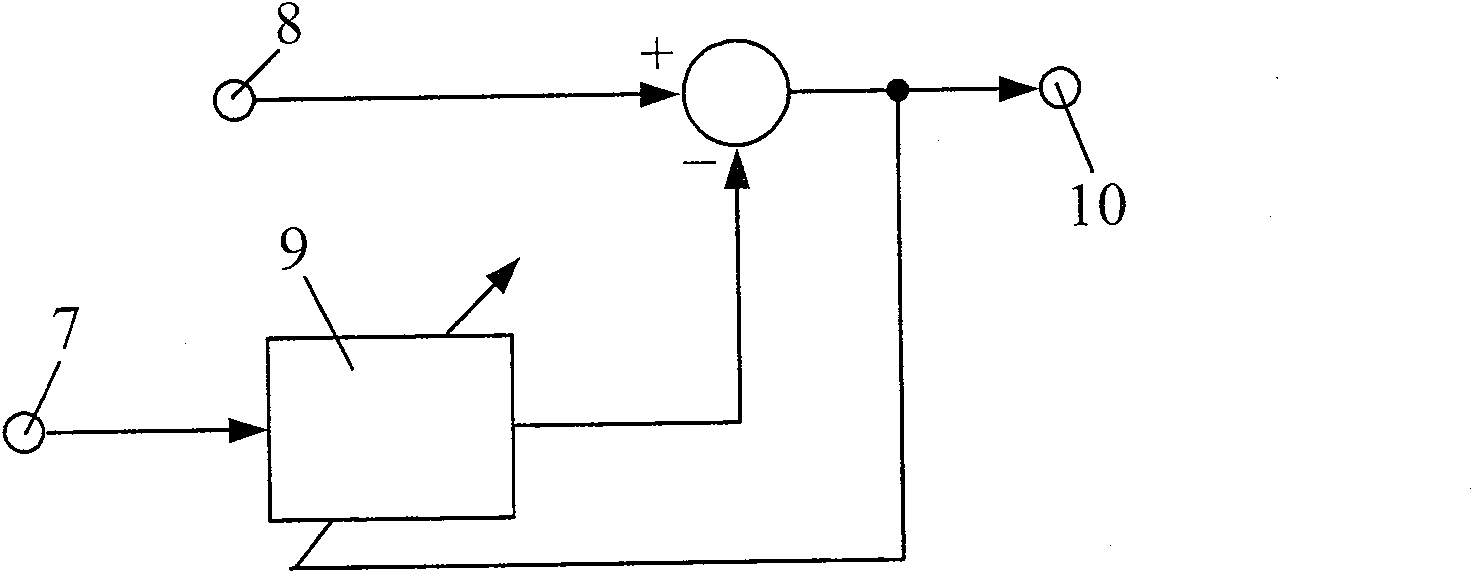

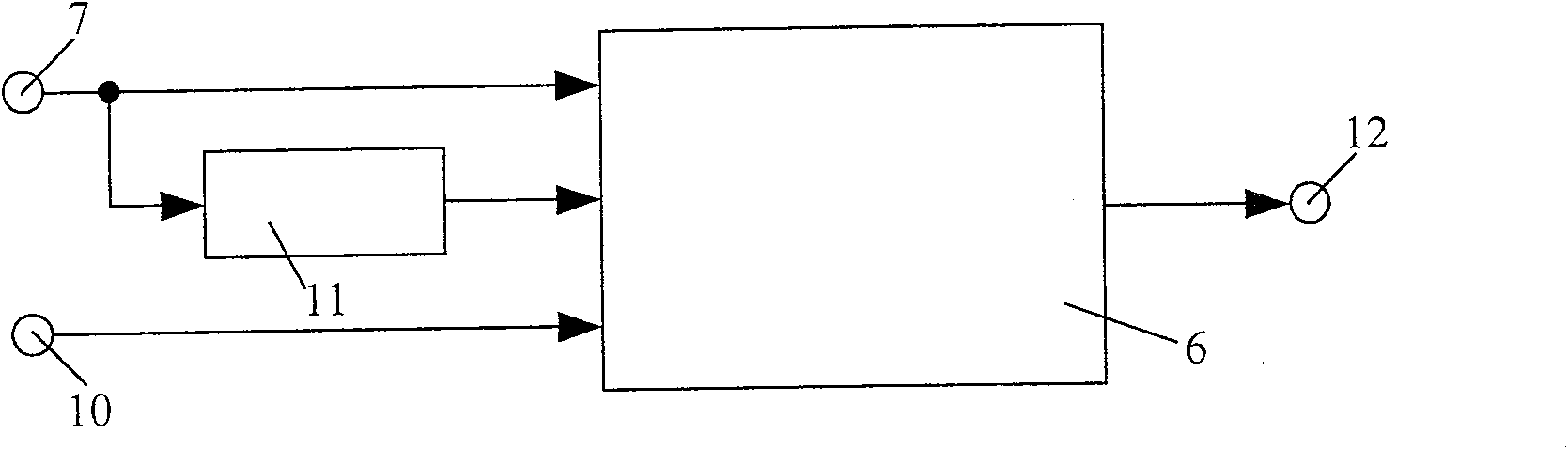

[0020] 2 The frequency of the adaptive notch filter reference signal 7 is the frequency at the resonance peak of the vibration table.

[0021] 3. The input acceleration signal of the electro-hydraulic servo vibration table is subtracted from the acceleration response signal to obtain an error signal.

[0022] The 4LMS adaptive filtering algorithm adjusts the weight of the adaptive notch filter 6 online in real time according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com