Ion injection method for producing NOR FLASH chip

A technology of ion implantation and ion implantation machine, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems that the current channel cannot be guaranteed, and achieve the effect of improving yield and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

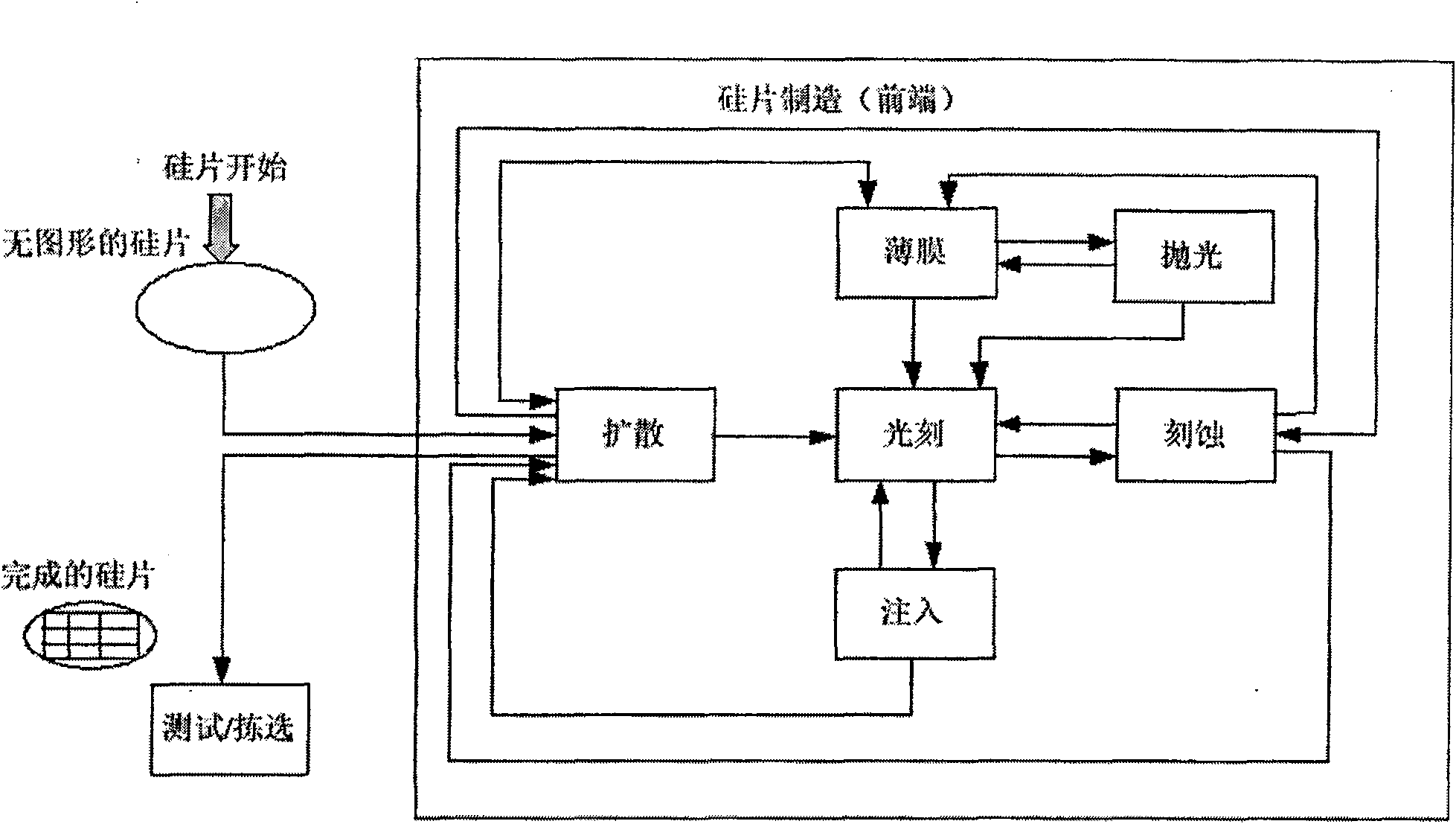

[0022] please participate figure 1 , the figure mainly introduces the flow chart of the planarization process in chip manufacturing, which mainly includes diffusion steps, photolithography steps, etching steps, ion implantation steps, film deposition steps, polishing steps, and testing and sorting steps. What the present invention improves is the ion implantation step.

[0023] The invention discloses an ion implantation method for manufacturing a NOR FLASH chip, especially an ion implantation method for a 0.18nm NOR FLASH chip. The ion implantation method includes an ion implantation step: the gas is ionized in an ion implanter with impurities such as arsenic and phosphorus to be doped, and a high voltage and a magnetic field are used to control and accelerate the ions, so that the high-energy impurity ions penetrate the rubber-coated silicon wafer s surface. In order to ensure that the current channel at the bottom of the NOR FLASH chip is unblocked in the present inventio...

Embodiment 2

[0026] In this embodiment, in the ion implantation step, the implanted arsenic ion concentration is greater than or equal to 4*10 15 Pieces / CM 2 , the speed of implanted arsenic ions is greater than or equal to 25Kev. For example, in the ion implantation step, the implanted arsenic ion concentration is 4*10 15 Pieces / CM 2 , the speed of implanted arsenic ions is 25Kev.

Embodiment 3

[0028] In this embodiment, during the ion implantation process, in the ion implantation step, the implanted arsenic ion concentration is greater than or equal to 5*10 15 Pieces / CM 2 , the speed of implanted arsenic ions is greater than or equal to 30Kev. For example, in the ion implantation step, the implanted arsenic ion concentration is 5.5*10 15 Pieces / CM 2 , the speed of implanted arsenic ions is 30Kev.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com