Mechanical pipe pole connecting hoop detecting apparatus for working with pressure

A technology of pressure-bearing operation and detection device, which is used in surveying, wellbore/well components, earth-moving drilling and production, etc. Reliable work and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

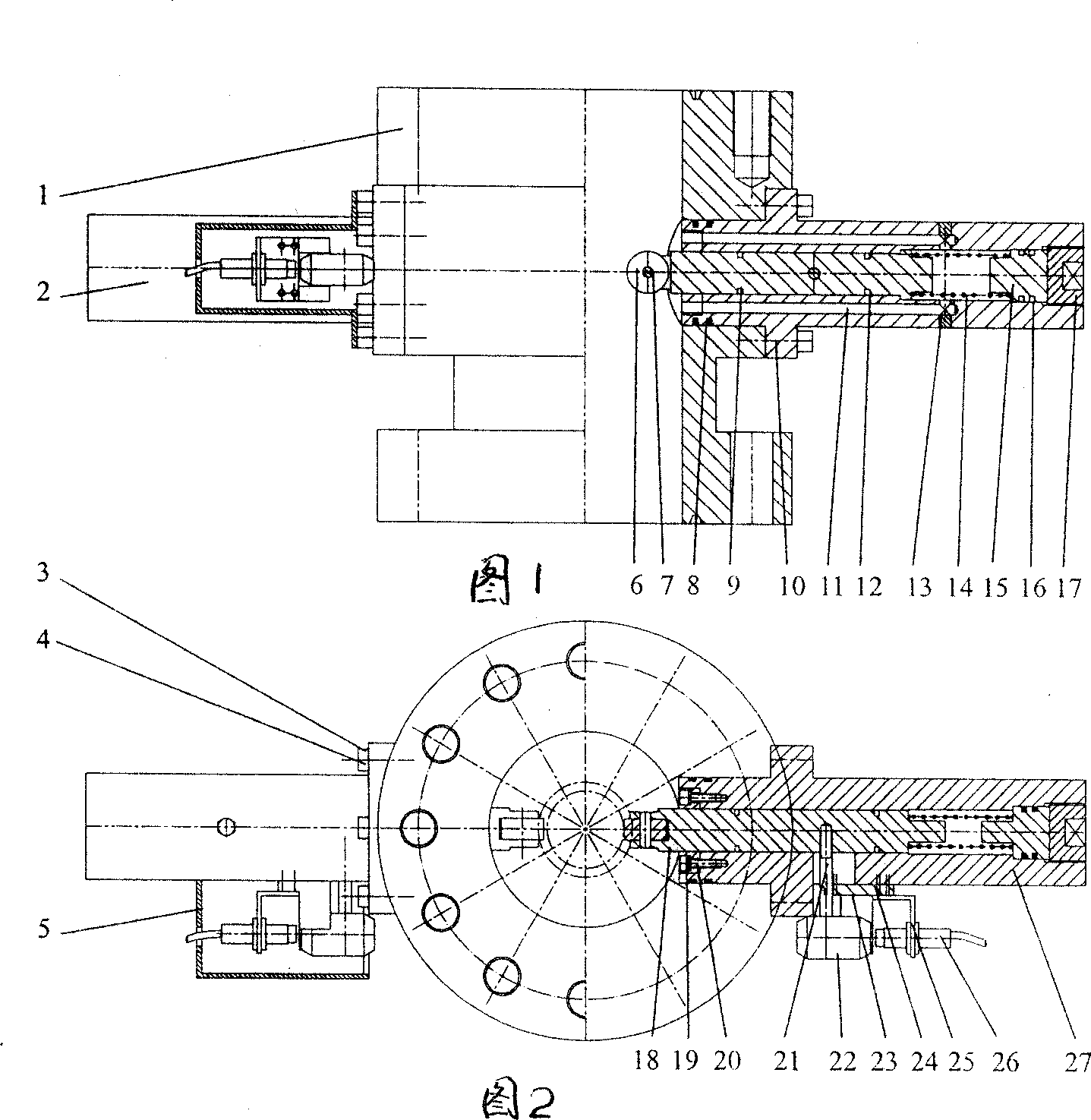

[0007] The present invention is provided by the following embodiments, and the present invention will be further described below in conjunction with the accompanying drawings.

[0008] As shown in the figure, the present invention consists of a housing 1, a detection component 2, a detection roller 6, a roller mandrel 7, a detection plunger 8, a compression spring 14, an adjustment piston 15, a plug 13, a detection component housing 27, a limit Ring 19, displacement transmission rod 21, displacement transmission guide block 22, sensor guide seat 23, sensor bracket 25, proximity displacement sensor 26, connecting screw 20, sealing ring 8, 9, 12, 16, protective cover 5 and bolt 3, nut 4 components, its structure and assembly relationship are as follows: a set of detection component housing 27, detection roller 6, roller mandrel 7, limit ring 19, detection plunger 18, compression spring 14 are arranged symmetrically on the left and right sides of the housing. , the adjusting pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com