Hydrogen energy type high-temperation, vacuum sterilizing apparatus

A technology of high-temperature vacuum and sterilizer, which is applied in the method of waste disinfection or sterilization, heating, etc., can solve the problems of large volume of cooking equipment, unsuitable for moving equipment, long processing time, etc., and achieves superior disinfection performance, simple structure, improved The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

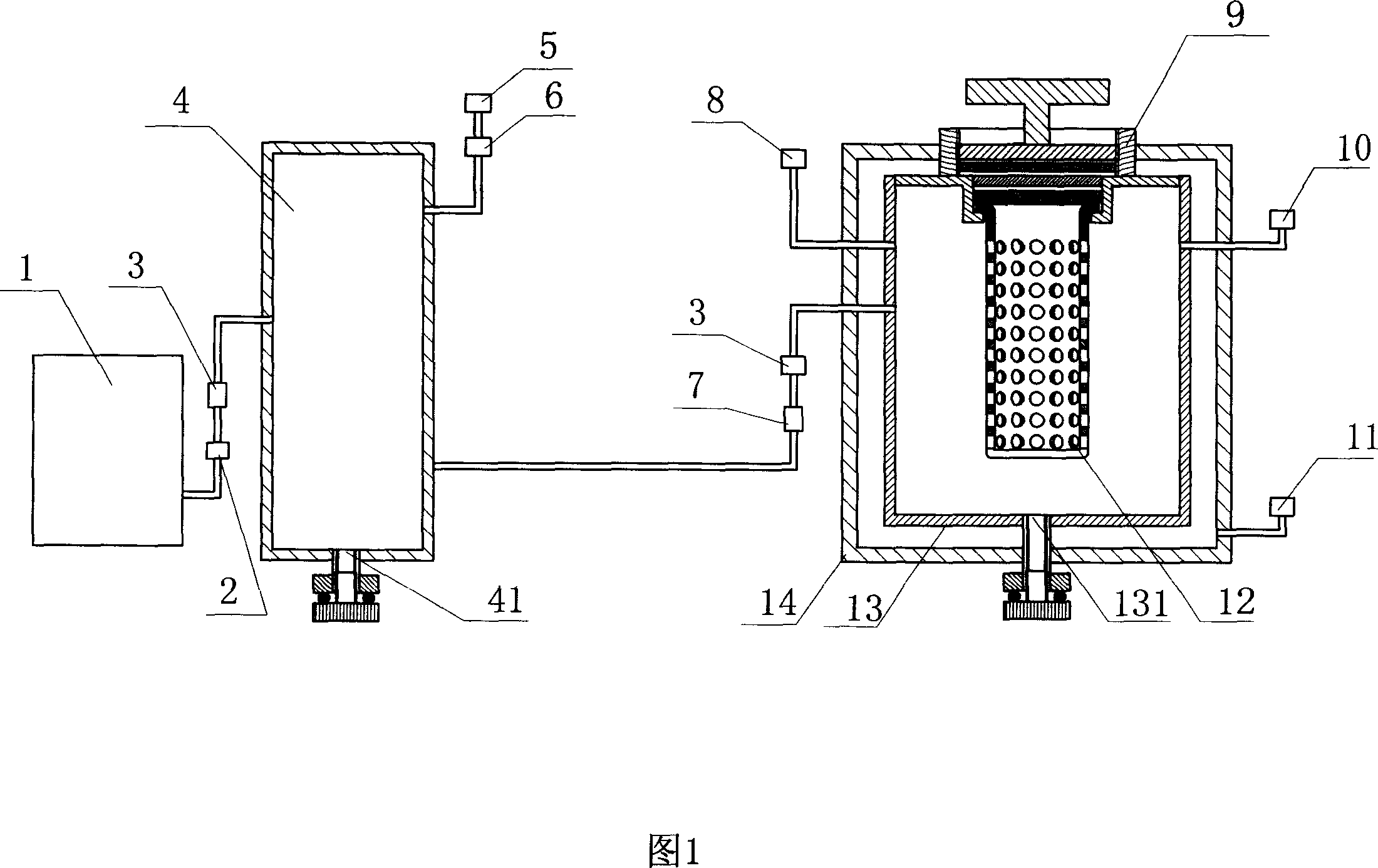

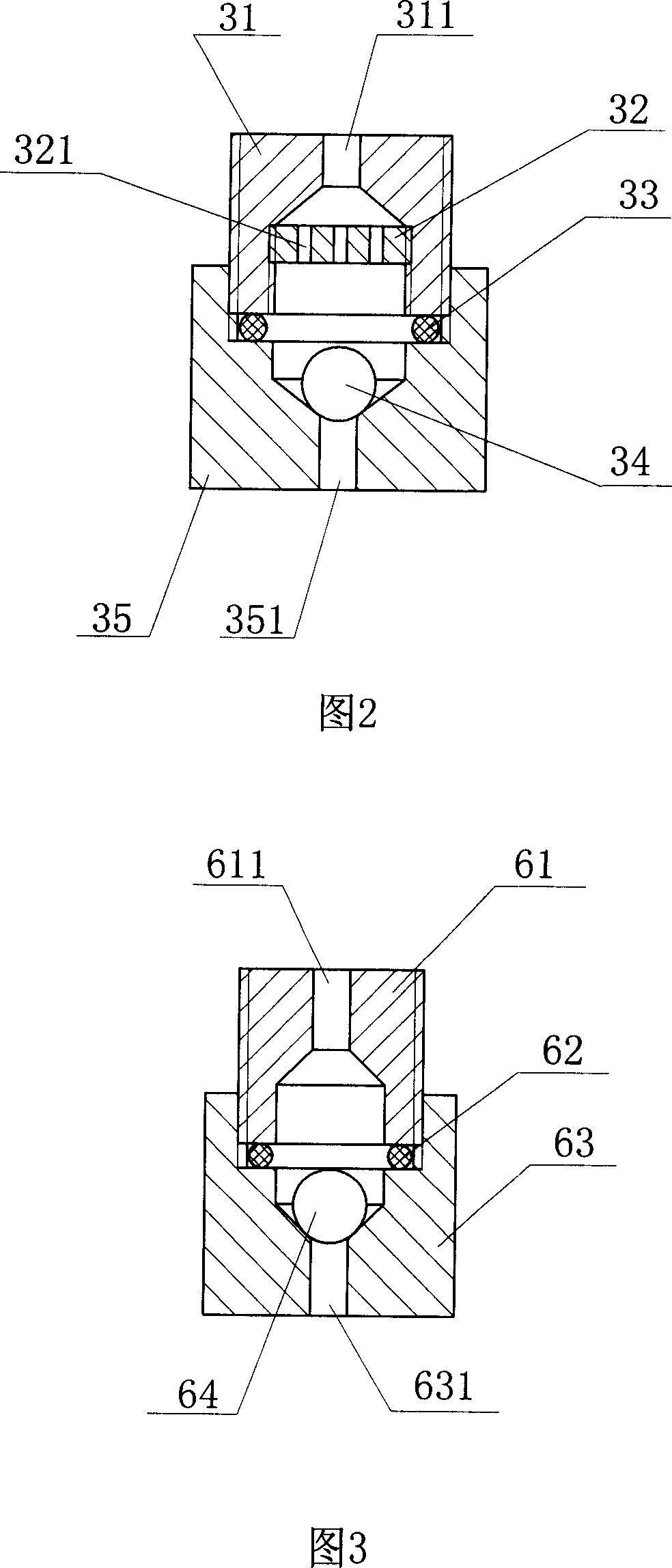

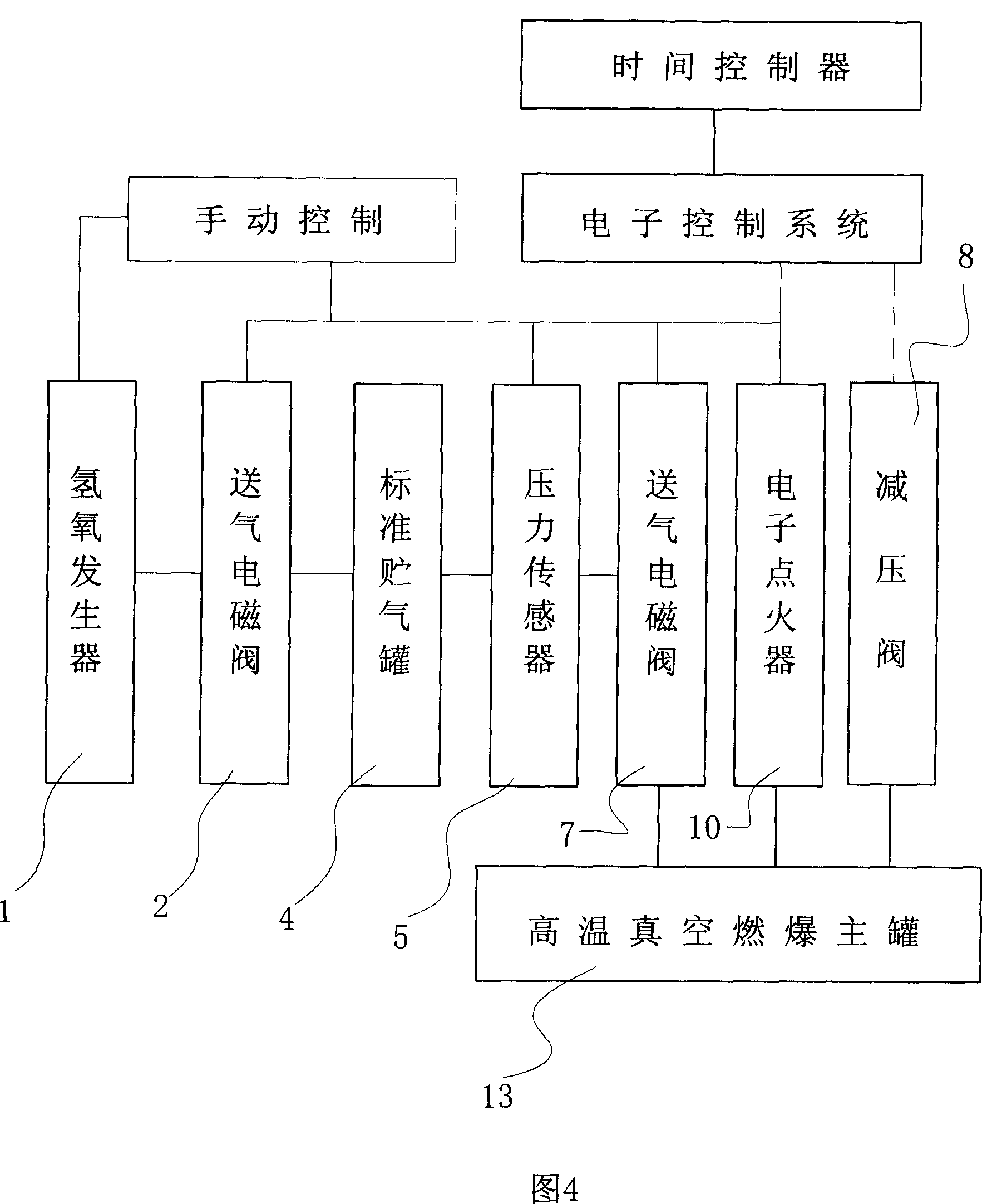

[0019] As shown in Fig. 1-Fig. 4, the hydrogen energy high-temperature vacuum sterilization and disinfection machine of the present invention mainly includes a sealed container, a hydrogen-oxygen generator 1, an air storage tank 4, a pressure sensor 5, a pressure reducing valve 8, an electronic igniter 10, Hydrogen and oxygen intake solenoid valves I7, II2 and explosion-controlled protectors I3, II6, of which:

[0020] The airtight container is mainly composed of a hydrogen-oxygen explosion main tank 13 and a stainless steel net bucket 12 through the top cover 9 and the sealing ring, which are sealed and connected with fasteners, wherein the stainless steel net bucket 12 is suspended in the explosion main tank 13 , used to place objects to be sterilized. And in order to achieve sound insulation and heat preservation better, a soundproof tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com