High temperature energy ball grinder

A technology of energy balls and mills, applied in furnaces, grain processing, vertical furnaces, etc., can solve the problems of difficult synthesis of quality and performance materials, high solid-phase reaction temperature, and low reaction power, and achieve simple and compact structure, Strong working ability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

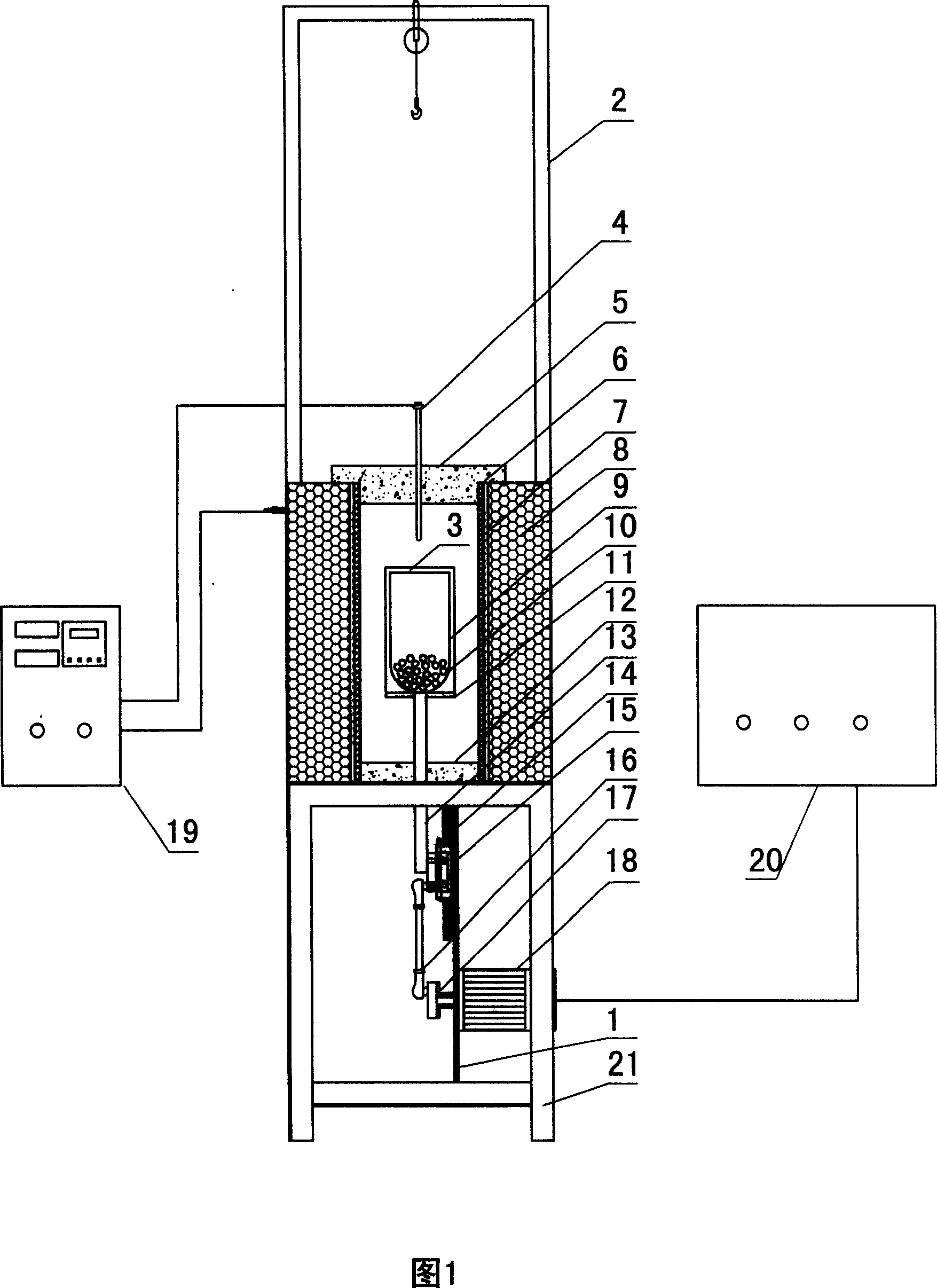

[0015] Embodiment 1: be the vibration type high-temperature energy ball mill, its structure as shown in Figure 1: comprise motor 18, ball mill tank 9, temperature controller 19, high-temperature furnace, speed governor 20 and transmission mechanism, ball mill tank 9 interiors are equipped with several Grinding balls 10, the high temperature furnace is placed on the bottom frame 21, the high temperature furnace is built with a ball mill pot 9, the ball mill pot 9 is equipped with a ball mill pot support 11, the ball mill pot support connecting rod 13 is connected with the motor 18 through the transmission mechanism, and the motor 18 is connected with the motor 18. The governor 20 is connected, and the thermocouple 4 is connected to the external temperature controller 19 through the high temperature furnace insulation cover 5 .

[0016] The transmission mechanism in this example is a vibration type, including cam 17, automatic slide block 15, automatic slide rail 14, joint bearin...

Embodiment 2

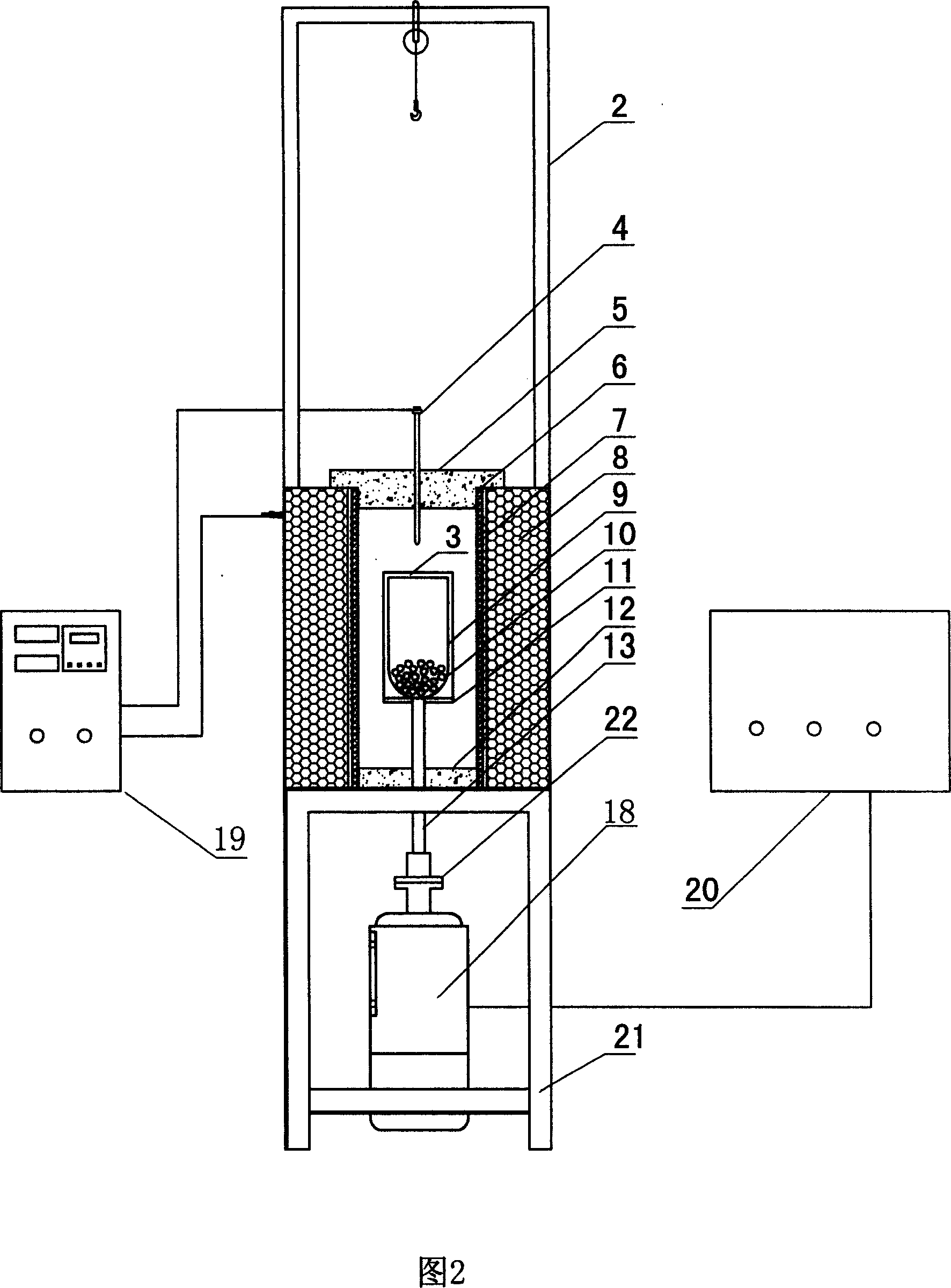

[0019] Embodiment 2: be the rotary high-temperature energy ball mill, its structure as shown in Figure 2: comprise motor 18, ball mill tank 9, temperature controller 19, high-temperature furnace, speed governor 20 and transmission mechanism, ball mill tank 9 interiors are equipped with several Grinding balls 10, the high temperature furnace is placed on the bottom frame 21, the high temperature furnace is built with a ball mill pot 9, the ball mill pot 9 is equipped with a ball mill pot support 11, the ball mill pot support connecting rod 13 is connected with the motor 18 through the transmission mechanism, and the motor 18 is connected with the motor 18. The governor 20 is connected, and the thermocouple 4 is connected to the external temperature controller 19 through the high temperature furnace insulation cover 5 .

[0020] In this example, the transmission mechanism is a rotary structure, and the opposite wheel 22 is installed on the output shaft of the motor 18, and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com