Method for sterilization, and eliminating accumulated calcium for electrobath

An electrolytic cell and voltage technology, applied in the direction of electrolysis process and electrolysis components, can solve the problems of easy accumulation of calcium on the cathode plate, inconvenient use, and uneconomical benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make those skilled in the art easily understand the content of the device of the present invention and the beneficial effects that can be achieved, a specific embodiment is now listed, and the detailed description is as follows in conjunction with the accompanying drawings:

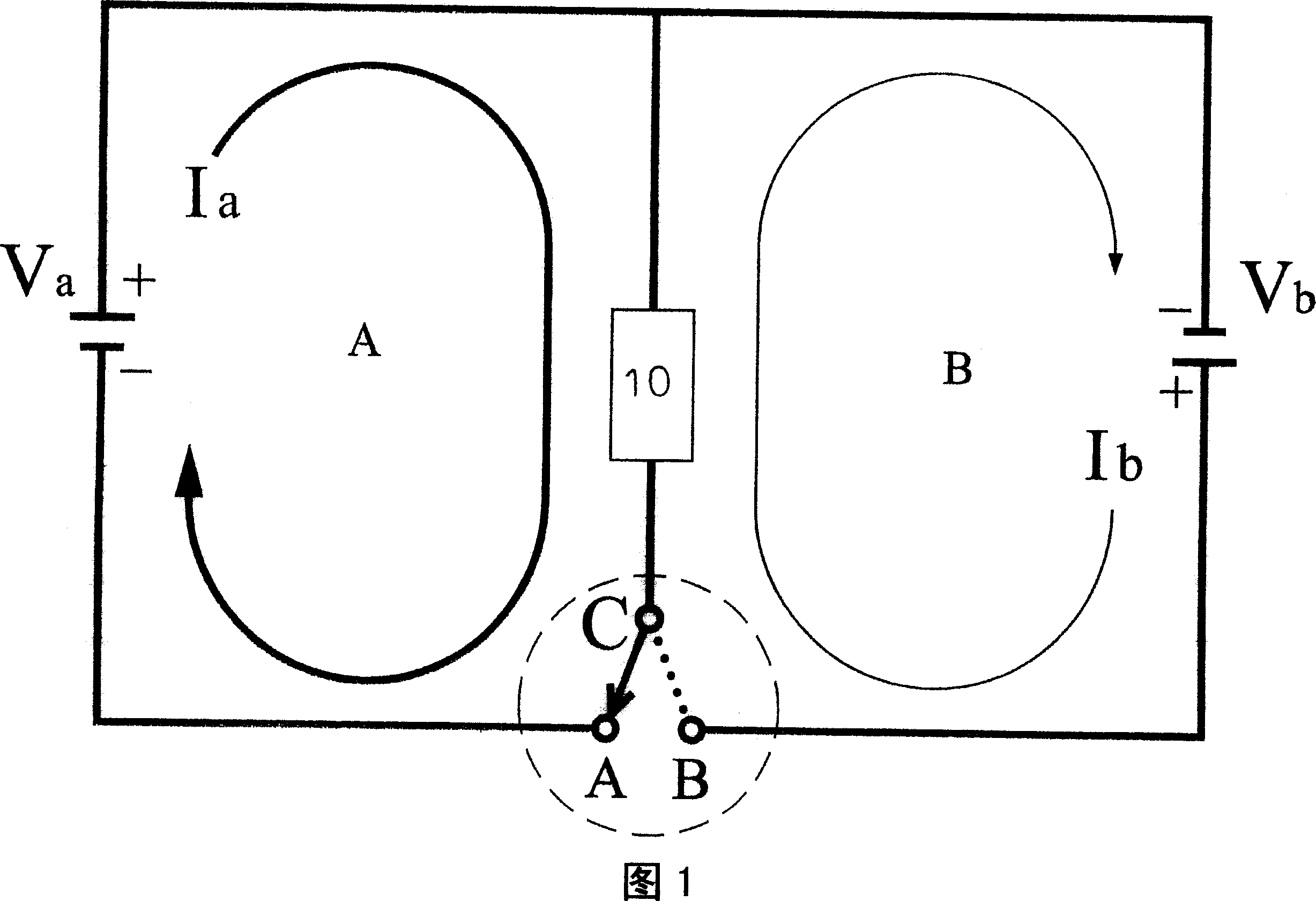

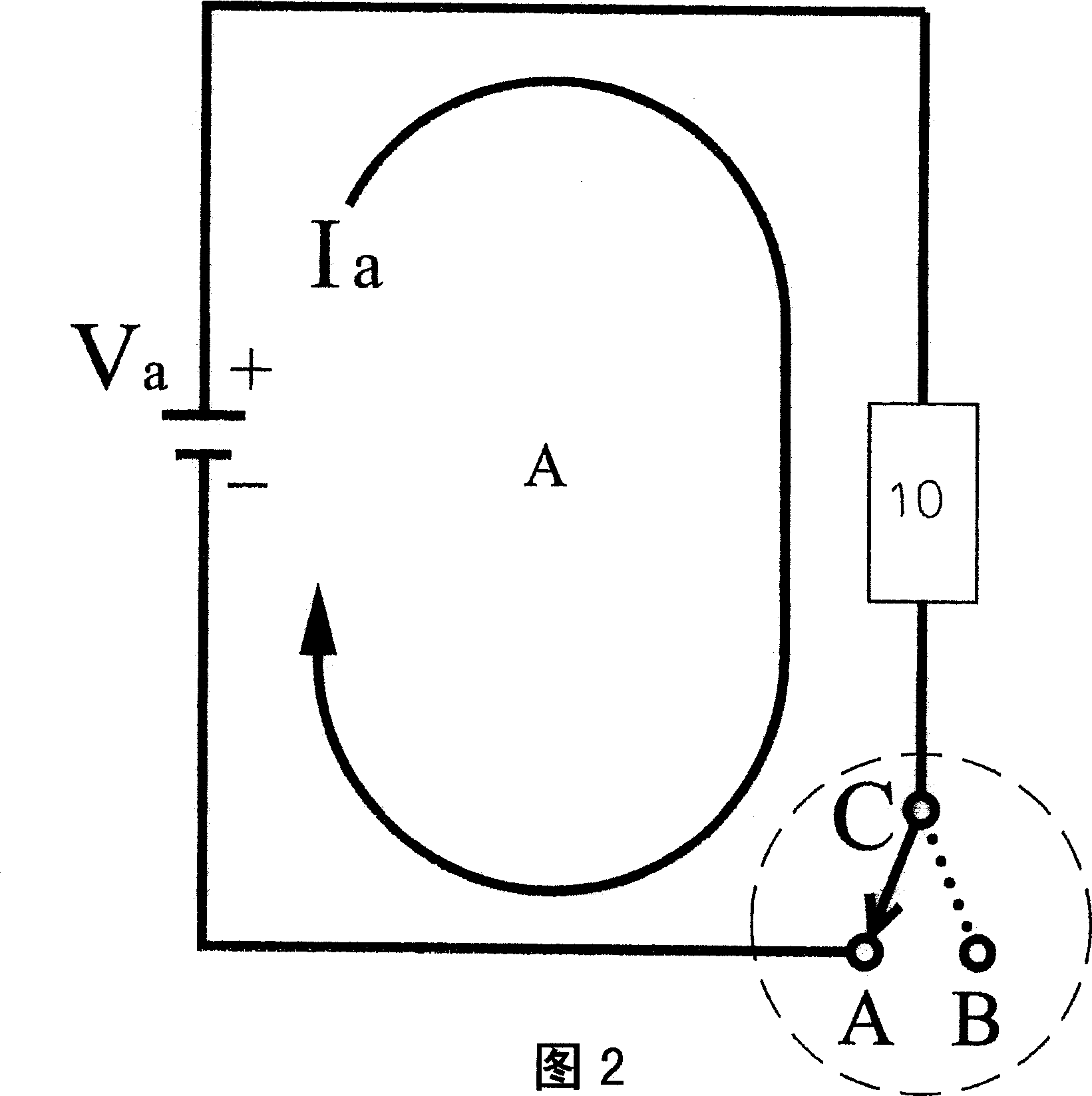

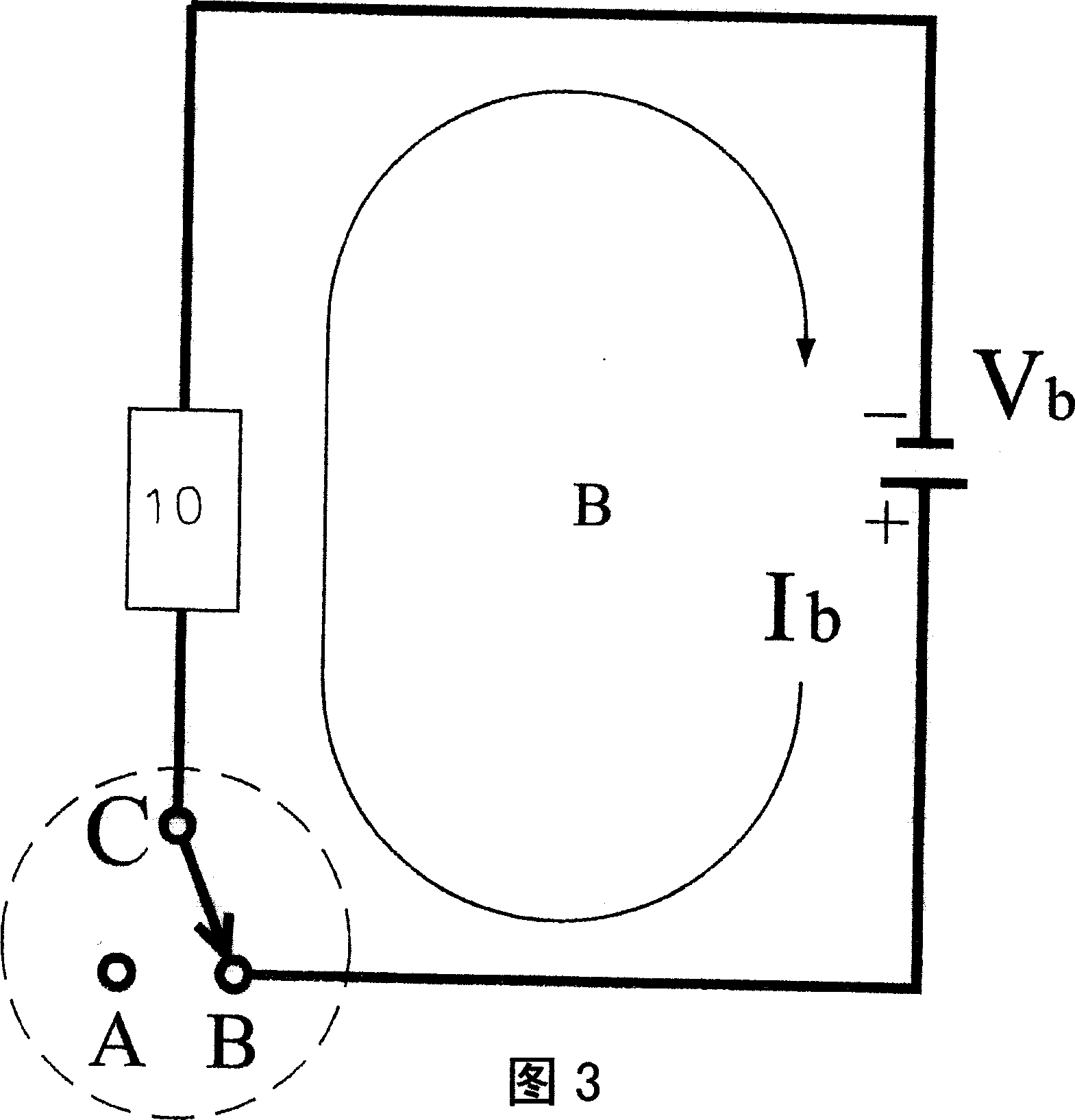

[0022] Please refer to Fig. 1 for a method for sterilizing an electrolyzer and removing calcium deposits. Fig. 1 shows a schematic circuit diagram of the present invention. The main reason is that the electroanalysis circuit (electroanalysis circuit) A of the electrolytic cell (electrode chamber) 10 is applied with a generally normal working voltage, and an electronic instant switch (electronic instant switch) C is used to select the electroanalysis circuit (electroanalysis circuit) A (as shown in the figure) 2: a schematic diagram of the electrolysis circuit of the present invention) or a pulse high voltage circuit (high voltage pulse circuit) B (as shown in Figure 3: a schematic diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com