Device and method for preventing crystallization of urea dissolution tank

A technology of dissolving tank and urea, applied in the directions of dissolving, dissolving, mixing, etc., can solve the problems of accelerating the crystallization and corrosion of the entire passage of the bucket elevator, so as to solve the problem of urea crystal plate dead, avoid crystal plate dead, and reduce deposition blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

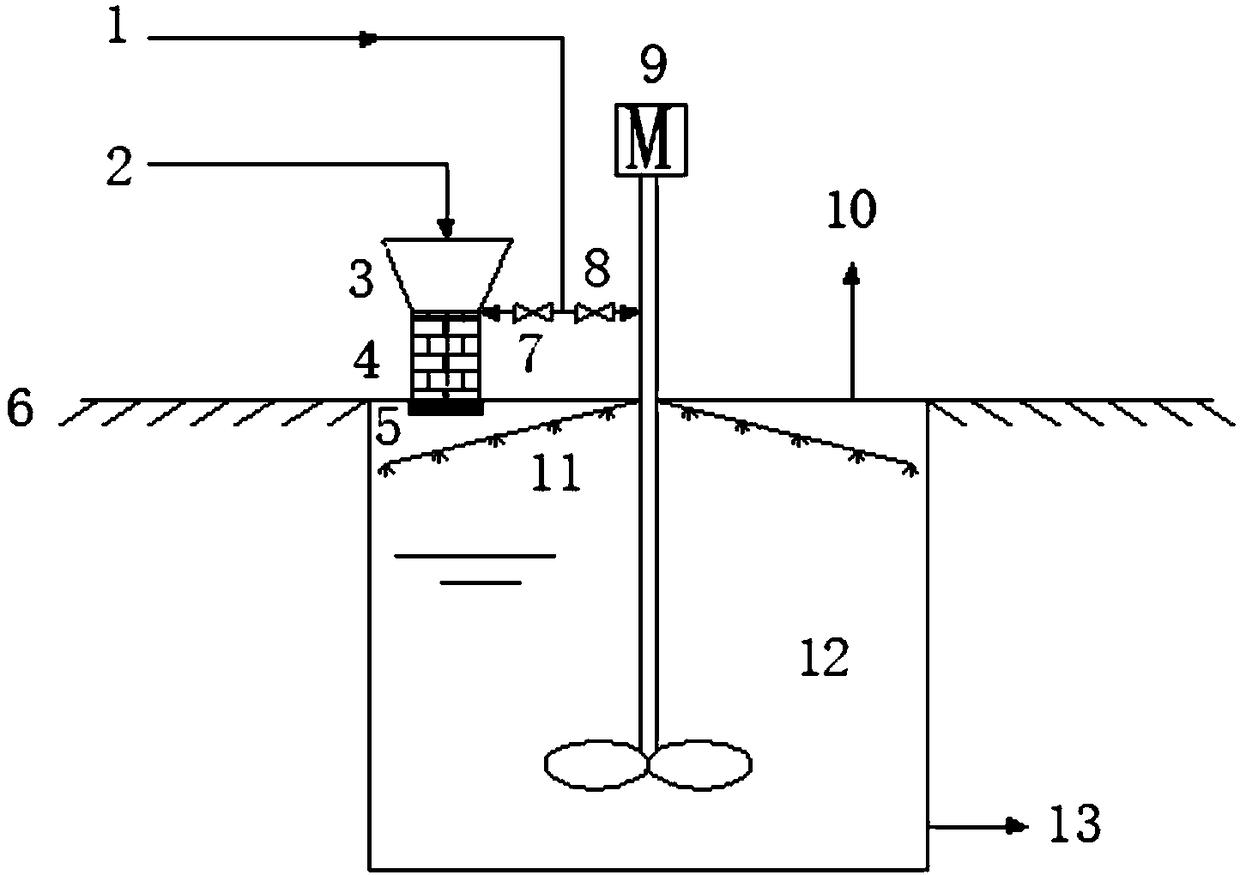

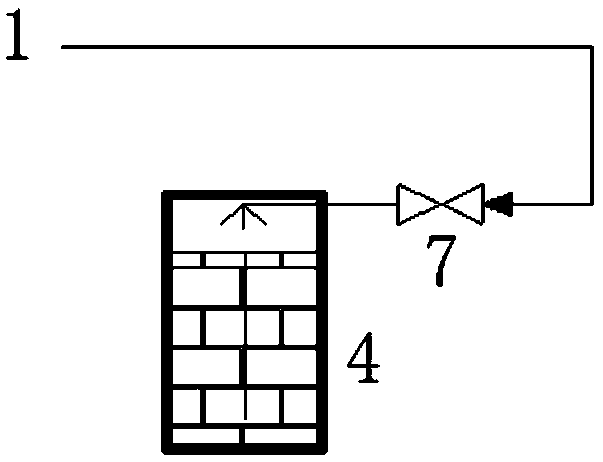

[0032] The device of the present invention, such as figure 1 As shown, it mainly consists of urea dissolving tank 12, urea crusher 3, urea feeding port 2, feed filter screen 4, dissolving tank gate valve 5, mixer 9, exhaust port 10, discharge port 13 and desalinated water flushing spray system Composition; the desalinated water flushing spray system includes a desalinated water main pipe 1, a desalinated water flushing pipe 7, a desalted water spray pipe 8 and a micro-spray rod 11; the upper part of the urea dissolving tank 12 is provided with a dissolving tank gate valve 5 and a drain The gas port 10 is provided with a discharge port 13 at the bottom; the urea feed port 2 is provided on the urea crusher 3, and the feed filter 4 is provided between the urea crusher 3 and the dissolving tank gate valve 5; the desalted water main pipe 1 is in communication with the desalinated water flushing pipe 7 and the desalinated water spray pipe 8, and the desalted water flushing pipe 7 is...

Embodiment 2

[0039] A kind of method for preventing the crystallization of urea dissolving tank of the present invention, on the basis of the device described in embodiment 1, comprises the following steps,

[0040] Step 1, first pour the desalinated water into the urea dissolving tank 12 through the desalinated water flushing pipe 7 by spraying through the feed filter 4, and then add the crushed and removed urea particles into the urea dissolving tank 12, and close it after the feeding is completed Dissolving tank gate valve 5;

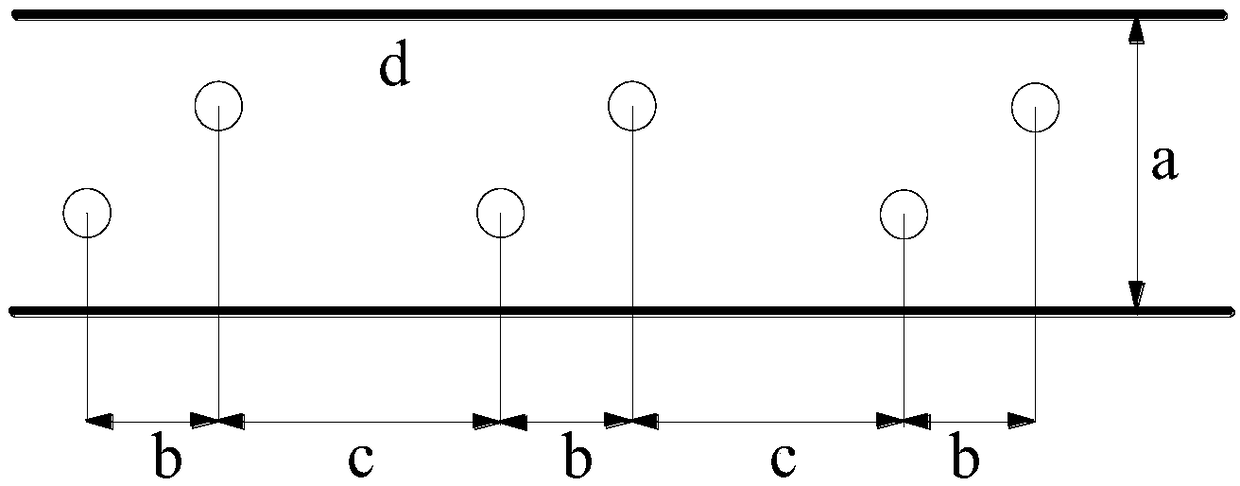

[0041] Step 2, during the stirring process for the preparation of the urea aqueous solution, the desalted water is sent into the micro-spray rod 11 through the de-salted water spray pipe 8 through the stirring axis of the mixer 9, and the working pressure of the micro-spray rod 11 is 0.05Mpa-0.1Mpa, And spray through some water spray holes to suppress the entrainment of mist caused by stirring and temperature rise in the urea dissolving tank 12, so as to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com