Multielement analysis device for on flowing detection and detection method

A technology of multi-element analysis and detection method, which is applied in the field of X-ray detection and analysis instrument devices, and achieves the effect of simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

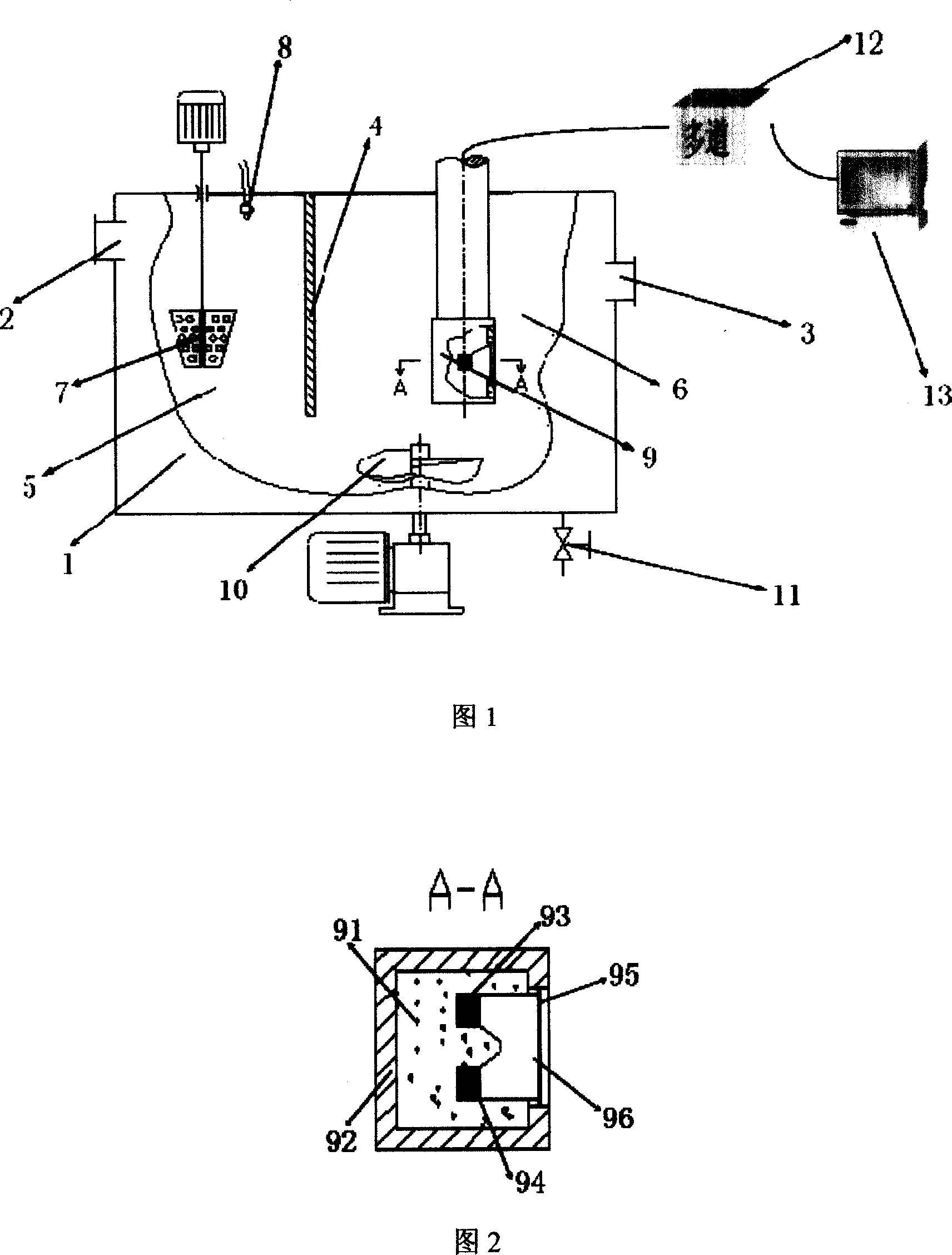

[0036] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT: The structure and usage method of the present invention will be described in detail in conjunction with the accompanying drawings.

[0037]The in-flow detection multi-element analysis device of the present invention is equipped with a partition 4 in the housing 1 of the measuring device. The housing is divided into an ore feeding bin 5 and a measuring bin 6. There is a feeding port 2 on the top of the silo, and an agitator 7 is installed in the ore feeding silo. There are many small holes on the blade of the agitator with a diameter of about 1 cm, so that the stirring force is small and the discharge of air bubbles can be promoted. . By constantly stirring the pulp, all the air bubbles in the pulp are stirred out. In the process of flotation or reverse flotation, the agent that promotes the generation of air bubbles is added to the pulp, and when the pulp is disturbed, a large number of air bubbles will be generated. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com